Horizontal Belt Conveyor

Used to move items or materials horizontally along a straight path, belts are made of durable materials, such as rubber or fabric, capable of carrying various types of loads.

Belt Width: 400/500/650/600/800/1000/1200/1500mm

Conveying length: 10-30 meters

Conveying capacity: 30-3000t/h

Conveying speed: 1.25-2.0m/s

Conveyor belt material: rubber, polyurethane, PVC, etc.

Horizontal belt conveyor is a conveyor system that uses a continuous belt to move materials horizontally. It is commonly used in industries such as manufacturing, mining, agriculture, and logistics for efficient material handling and transportation. The basic design of a horizontal belt conveyor consists of a flat, continuous belt supported by idler rollers. The belt is driven by a motorized pulley or a series of pulleys, which propels the belt forward, causing the materials on the belt to move. The materials can be loaded onto the belt manually or through automated systems such as hoppers or chutes.

-

Horizontal Belt Conveyor for Sale

Types

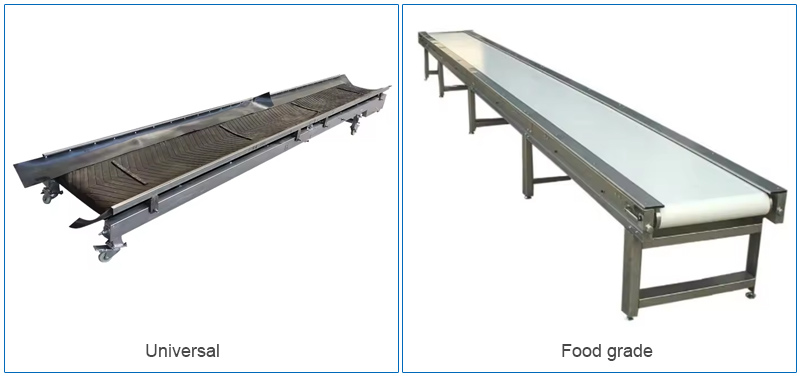

Horizontal belt conveyors can be classified according to different classification standards. Here are some common classification methods:

1. Purpose:

Universal horizontal belt conveyor: Suitable for general material transportation in a variety of industries and applications.

Special Purpose Horizontal Belt Conveyors: Designed and customized to meet specific industry or application needs, such as food grade horizontal belt conveyors for the food industry or chemical conveyors for the chemical industry.

2. Belt type:

Flat belt conveyor: Use flat belts for material transportation.

Belt-type horizontal belt conveyor: Belt-type belts are used for material transportation and are often used for longer distance transportation.

Features

Efficiency: Horizontal belt conveyors offer efficient material handling solutions, allowing for the continuous movement of goods along a straight path with minimal manual intervention.

Versatility: These conveyors can handle a wide range of products, from small items to large and bulky materials, making them versatile for various industries and applications.

Space Utilization: Horizontal belt conveyors help optimize space utilization in facilities by providing a streamlined and organized method of transporting materials horizontally.

Safety: When designed and operated correctly, horizontal belt conveyors contribute to a safer work environment by reducing the need for manual handling and minimizing the risk of injuries associated with material transport.

model

|

Width (mm) |

Conveying length(m) Power(kw) |

Transfer speed (m/s) |

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

Video

Structure

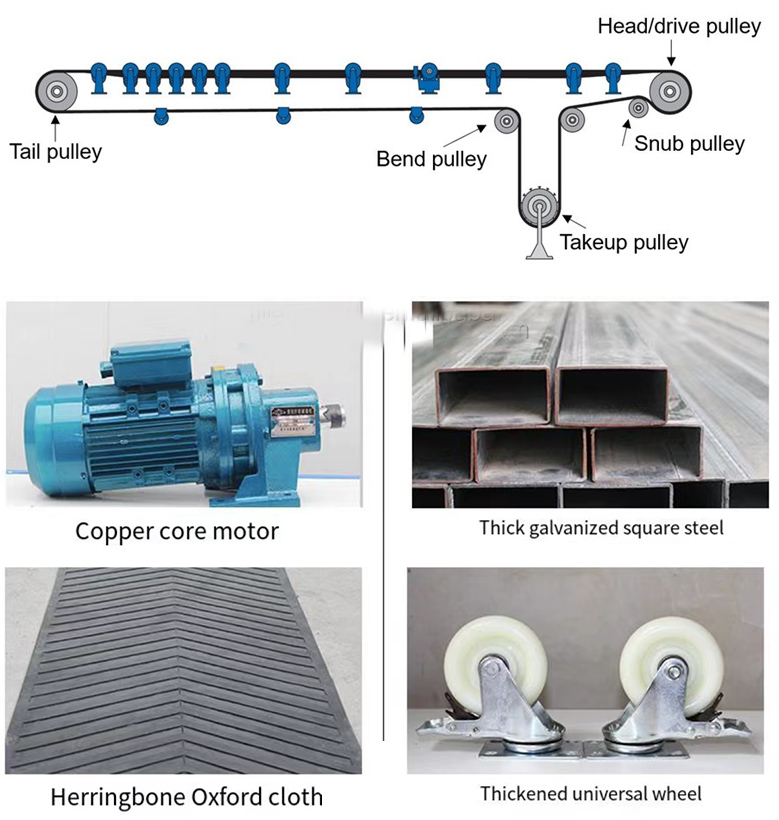

Belt: The conveyor belt is the primary component of a horizontal belt conveyor system. It is typically made of durable materials such as rubber, PVC, or fabric and is designed to carry and transport goods along a horizontal path.

Rollers or Pulleys: The belt runs on rollers or pulleys, which help support and guide the belt as it moves along the conveyor system. These components ensure smooth and consistent movement of materials.

Drive Mechanism: Horizontal belt conveyors are powered by a drive mechanism, such as a motor or gearbox, which provides the necessary force to move the belt and transport materials along the conveyor.

Options

Odd lengths and widths

Stainless steel construction

Variable speed controllers

Angle and channel guard rails

Different belt styles

Drive locations

Energy-efficient motors

Applications

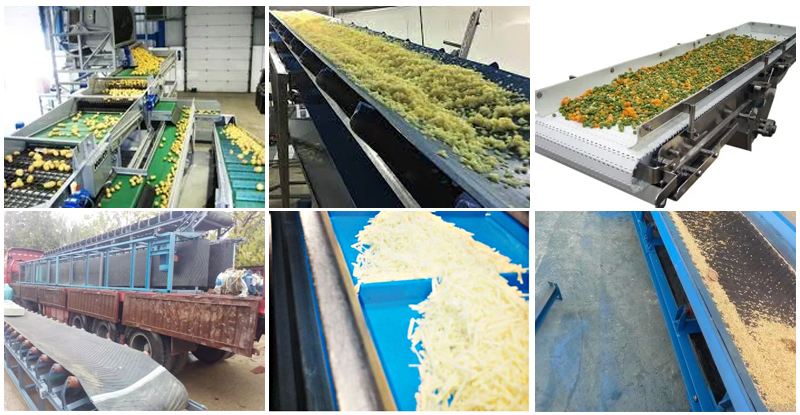

Horizontal belt conveyors are widely used in various industries for efficient material handling and transportation. Some common uses of horizontal belt conveyors include:

Manufacturing: Transporting raw materials, components and finished products between stages of production. They facilitate the movement of items on an assembly line, enabling efficient and organized manufacturing operations.

Distribution centers and warehouses: Used to move items from receiving areas to storage locations, between different processing areas, and for order fulfillment and shipping processes.

Mining and Quarrying: For transporting bulk materials such as coal, ore, aggregates and minerals. They enable the efficient and continuous movement of material from the point of extraction to processing or storage areas.

Agriculture: For handling crops, grains and other agricultural products. They are used in processes such as truck loading and unloading, storage facilities, and transport of harvested crops for further processing.

Food processing: used to transport food, packaging materials and ingredients. They are designed to meet the hygienic and hygienic requirements of the industry and can be equipped with features such as a wash down function and food grade belt material.

Solutions by Industry

Here are three customer cases of horizontal belt conveyors:

-

Food processing plants

Solution: A food processing plant in Australia produces a variety of food products, including packaged snacks and ready-to-eat meals. They needed a reliable conveying system to transport food between different processing stages and turned to a horizontal belt conveyor system specially designed for food handling. This delivery system ensures hygienic and efficient transportation of food products, maintaining product integrity and minimizing the risk of contamination. It facilitates the smooth flow of food, optimizes production lines and increases overall productivity.

-

Grain Handling and Storage

Solution: An independent Grain Storage in the United States operates a large facility for storing and processing a variety of grains such as wheat, corn, and barley. They needed an efficient system to move the grain from the receiving area to the storage silos and between the different processing units. They implemented a horizontal belt conveyor system specifically designed for handling grain. The conveyor system ensures gentle handling of the grain, preventing damage and maintaining its quality. It facilitates the smooth transfer of grain and optimizes storage and processing operations at the facility.

-

Fertilizer Production Plant

Solution: An agrochemical industry company in Iran produces various fertilizers for agricultural use. They needed a robust conveyor system to transport the large quantities of fertilizer between the different processing units and packing stations, a horizontal belt conveyor system was used, designed to handle the fertilizer safely. Conveyor systems facilitate smooth and efficient movement of fertilizer, ensuring accurate transfer and minimizing product loss or contamination. It optimizes production and packaging processes, increases overall productivity and reduces manual handling.