Loading belt conveyor

A conveyor system specifically designed to efficiently transfer goods or materials onto trucks, trailers, or containers.

Belt width: 400-1200mm

Fixed length: 3-26 meters

Extended length: 2.8-14 meters (can be customized)

Application: Widely used in various industries such as logistics, warehouses, distribution centers and manufacturing facilities.

product description

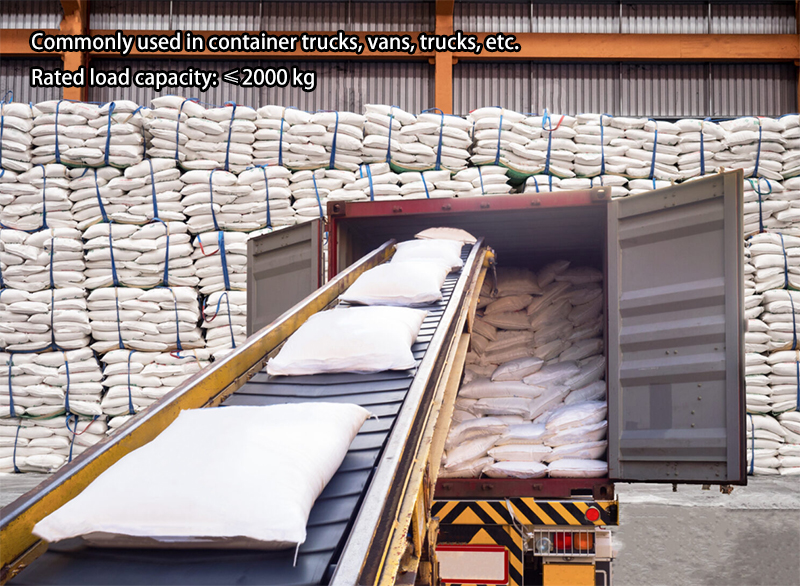

Loading belt conveyor, also called truck loading belt conveyor, is a type of conveyor system commonly used in industries for the efficient and automated loading of materials onto trucks, containers, or other transportation vehicles. These conveyors consist of a continuous belt that moves along a designated path, carrying materials from one point to another. Loading belt conveyors play a crucial role in streamlining the loading process, reducing manual labor, and improving efficiency in material handling operations.

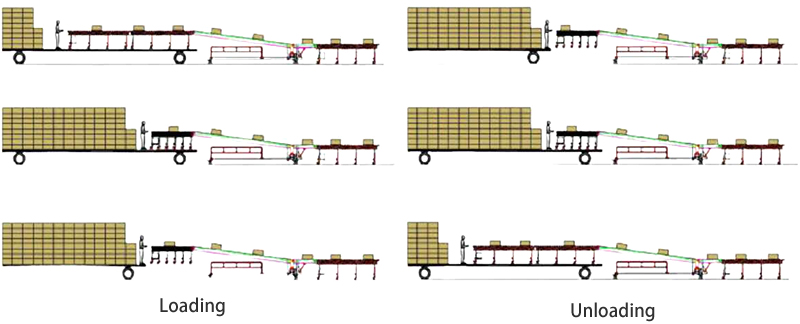

Types of loading belt conveyor

Loading belt conveyors come in various types, each designed to suit specific loading requirements. Some common types of loading belt conveyors include:

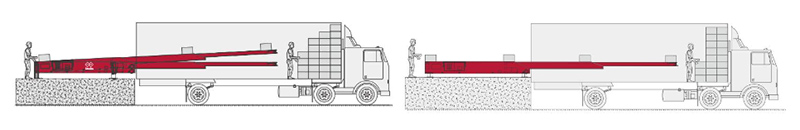

1.Portable truck loading belt conveyor: Used to load and unload trucks and containers at different locations, these conveyors are usually lightweight and equipped with wheels for easy mobility. Their height and angle can be adjusted to accommodate different truck sizes and loading requirements.

2.Climbing loading belt conveyor: Used to transport materials up and down ramps or vertical surfaces, these conveyors are equipped with cleats or baffles on the belt to prevent products from sliding back during transportation on inclined surfaces.

3.Telescopic loading belt conveyor: Adjustable length to reach different areas of the loading dock or truck for efficient loading and unloading. These conveyors have sections that can be extended or retracted to reach different distances, allowing flexibility to handle different truck sizes and loading scenarios.

Applications

Loading belt conveyors are versatile systems used in a variety of industries to enable efficient loading processes. Here are some key application scenarios that highlight the “loading” aspect of these conveyors:

Truck loading docks: Typically used in truck loading docks at warehouses, distribution centers, and manufacturing plants to efficiently load goods onto trucks for transportation.

Container handling: Used to load and unload containers onto ships and trucks, facilitating the rapid and orderly transportation of goods.

Distribution centers: Used to load products onto trucks for delivery to retail stores or customers, ensuring timely and accurate order fulfillment.

Mining and quarrying operations: Loading mined materials (such as ore, gravel, or aggregates) onto trucks or processing equipment for transportation.

Construction sites: Used to load construction materials (such as sand, gravel, or concrete) onto trucks for transportation to the job site.

Working principle

Here’s how a loading belt conveyor works:

Material Loading: Products are placed on the infeed end of the conveyor belt. This can be done manually or automatically using other conveyor systems feeding into the loading conveyor.

Belt Movement: The conveyor belt is powered by a motor and drive system, causing it to continuously move in a forward direction. The belt material is typically made of rubber or PVC with cleats or grips to improve traction and prevent items from slipping during transport.

Material Elevation (Optional): Some loading belt conveyors can be adjusted to an incline, allowing them to elevate materials to the height of the truck bed. This is particularly useful for high-profile trucks or containers.

Product Discharge: Once the materials reach the end of the conveyor belt, they discharge onto the waiting truck or trailer.

Features

Efficient loading operations: The ability to efficiently transfer materials to trucks, containers or other conveyor systems, simplifying the loading process and reducing manual labor.

Increased loading speed: Loading speed can be significantly increased by automating cargo transfers, thereby reducing loading times and increasing productivity.

Reduced risk of damage: By providing a smooth and controlled loading process, these conveyors help minimize the risk of product damage during loading, especially for fragile or sensitive goods.

Flexible Loading Configurations: These conveyors can be customized with various loading configurations such as adjustable height, angle and extension to suit different loading requirements.

Labor Savings: By automating the loading process, loading belt conveyors reduce the need for manual labor, thereby saving costs and increasing work efficiency.

video

Model parameters

| Type | section | Fixed Length (A) | Extension length (B) | Total Length (C) | Belt Length (W) |

| DH-2-6A/4B | 2 | 6000 | 4000 | 10000 | 600/800 |

| DH-3-5A/7B | 3 | 5000 | 7000 | 12000 | 600/800 |

| DH-3-6A/8.6B | 3 | 6000 | 8600 | 14600 | 600/800 |

| DH-4-5A/10B | 4 | 5000 | 10000 | 15000 | 600/800 |

| DH-4-6A/12.6B | 4 | 6000 | 12600 | 18600 | 600/800 |

Options

Loading belt conveyor has many custom design options to meet the specific needs of different industries and applications:

Length and width customization: The length and width of the conveyor can be customized according to specific needs to accommodate different sizes of loading areas and materials.

Height adjustment: The height of the conveyor can be adjusted to accommodate loading vehicles or containers of different heights.

Tilt angle adjustment: Some loading belt conveyors can adjust the tilt angle to effectively load materials under tilt.

Mobility: Some loading belt conveyors are designed to be movable with wheels for flexible movement and positioning in the work area.

Speed adjustment: The speed of the conveyor can be adjusted to achieve optimal loading speed and efficiency.

Additional functions: Safety functions and additional functions such as emergency stop buttons, protective covers, sensor detection, etc. can be customized as needed.

product structure

1. Steel plate: 16Mn steel plate, strong rigidity, high bending strength, stable structure and strong impact resistance.

2. Interface: The connection of the side plate and cover plate is connected by countersunk head screws above grade 8.8, and the welding place is tight and smooth.

3. Copper core motor: high-quality copper core motor is processed with high-quality steel, high-power all-copper wire, fast, accurate and durable.

4. Terminal: The terminal is designed with anti-collision function. When the anti-collision resistance is greater than 5kg, the equipment will automatically stop.

5. Liftable bracket: The bracket can be lifted and lowered freely, matching the height of cargo loading and unloading, making work easier and more efficient.

6. Belt deviation correction structure: The belt deviation correction structure design prevents the belt deviation from affecting the conveying, which is convenient and easy to maintain.

Solutions by Industry

-

Logistics Warehouse

A large logistics warehouse that handles the loading and unloading of various goods for distribution. They utilize loading belt conveyors at their loading docks to efficiently load trucks and trailers with packages, cartons, and palletized goods. The loading belt conveyors are integrated with their warehouse management system, allowing for seamless tracking and coordination of shipments.

-

Manufacturing Facility

A manufacturing plant that produces consumer goods and packages them for shipment. They employ loading belt conveyors as part of their packaging line to load finished products onto trucks. The loading belt conveyors are designed with adjustable heights to accommodate different truck bed heights, and they ensure a smooth and continuous flow of products for efficient loading.

-

Port Terminal

A busy port terminal that handles the loading of bulk materials onto ships for export. They rely on loading belt conveyors to transfer bulk commodities such as grains, ores, and coal from storage facilities onto the vessels. The loading belt conveyors are equipped with specialized features such as dust suppression systems and heavy-duty construction to withstand the harsh port environment and ensure safe and efficient loading operations.