Small Belt Conveyor

Designed to transport small parts and light products such as packaging, food, electronic components, etc., it is suitable for installation in small spaces and is very suitable for applications with limited space.

Belt width: 200mm-400mm

Belt speed: 0.5-2.5 m/s

Conveying capacity: 100 kg/h-1500 kg/h

Product Introduction of Small Belt Conveyor

Small belt conveyor is a compact and portable conveyor system that is designed for lightweight and low-capacity applications. It is commonly used in industries such as retail, packaging, assembly lines, and small-scale production processes where there is a need to transport small items or lightweight materials efficiently.

The belt width of a small belt conveyor is usually between 100mm and 600mm, with 200mm, 300mm, 400mm, etc. being common. It is suitable for conveying light materials such as packaging, food, electronic components, etc. The conveying capacity range is generally between 100 kg/h and 1500 kg/h, depending on the design and configuration.

Types of Small Belt Conveyor

Small belt conveyors can be classified based on their design, purpose, and features. Here are some common different types of small belt conveyors:

1.Straight small belt conveyor: The most basic type of small belt conveyor, used to transfer materials from one point to another, often used in applications such as packaging, assembly lines, etc.

2.Curved small belt conveyor: Designed to run along a curve, suitable for situations where you need to turn in a limited space, such as in a factory production line.

3.Incline small belt conveyor: A small belt conveyor with an inclined design, used to transport materials from a low place to a high place or vice versa, often used for material transfer between upper and lower floors.

4.Skirt small belt conveyor: A belt conveyor equipped with skirts on the edge of the conveyor belt. These skirts help control the material on the conveyor belt, prevent spillage and dust emissions, and are often used in industries where material control and dust control are critical, such as mining, construction, and bulk material handling applications.

Model parameters

| Model | Belt width (mm) | Belt speed (m/s) | Delivery capacity (kg/h) |

| B100 | 100 | 0.5 - 2.5 | 50 - 300 |

| B200 | 200 | 0.5 - 2.5 | 100 - 600 |

| B300 | 300 | 0.5 - 2.5 | 200 - 1200 |

| B400 | 400 | 0.5 - 2.5 | 300 - 1500 |

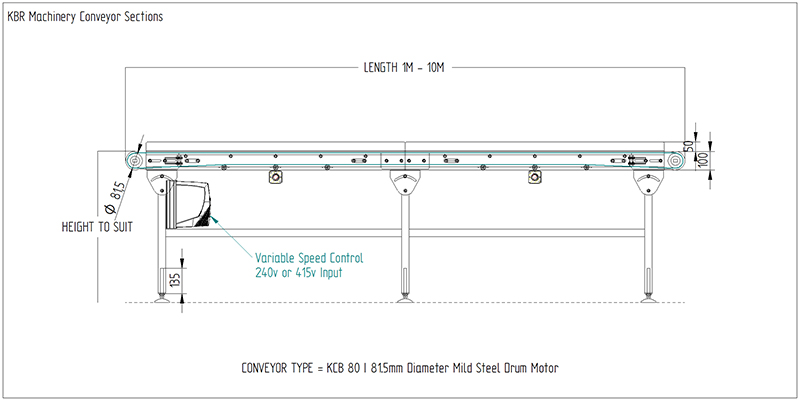

1. Conveyor length: generally 1 meter, 2 meters, 3 meters, 4 meters, 6 meters, 10 meters. Other sizes can be made.

2. Frame material: carbon steel, stainless steel, aluminum profile. Can be used in combination.

3. Conveyor side waist: height is generally 40mm, 80mm, 100mm.

4. Conveyor legs: 40×40, 40×60.

5. Conveyor feet: adjustable feet, casters.

6. Conveyor pallet: can be one-piece molding or split type.

7. Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE and PU belts are also available. Conveyor belts with other special requirements can also be selected. Belt colors are: white, green, black, etc.

8. Conveyor drive mode: adjustable speed, fixed speed, stepping, etc.

9. Conveyor speed regulation mode: frequency conversion speed regulation, electronic speed regulation, etc.

10. Accessories: A variety of customized functions can be added to the belt conveyor, such as sockets, drawers, anti-static wires, emergency stop buttons, etc.

Application

Small belt conveyors excel in multiple application scenarios due to their flexibility and adaptability. Here are some prominent application scenarios:

1. Electronic component assembly: In the production line of electronic products, it is used to transport small parts and components. The small design is easy to arrange in a small space and improve production efficiency.

2. Food processing: It is used to transport small packaged foods, fruits and vegetables, snacks, etc. It is easy to clean and maintain and meets hygiene standards.

3. Pharmaceutical production: In pharmaceutical factories, it transports small bottles of drugs and packaging materials, which can be seamlessly connected with automated equipment to ensure production continuity.

4. Logistics and warehousing: It is used to transport small items and parcels in warehouses. The flexible layout design can adapt to various cargo forms and improve sorting efficiency.

5. Plastic and metal processing: It is used to transport small processed parts and waste materials. It can quickly transfer materials during the processing process and reduce manual handling.

6. Laboratories and research institutions: It is used to transport samples and experimental materials. Small equipment takes up little space and is suitable for laboratory environments.

Video

Advantage

1. Space saving: The small design enables flexible arrangement in a small working environment, suitable for production lines or storage areas with limited space.

2. Strong flexibility: Small conveyors can be easily moved and reconfigured to adapt to different production needs and layout changes.

3. Easy installation: Due to its small size, the installation and commissioning process is relatively simple, reducing the time and cost of equipment online.

4. Economical and practical: Small belt conveyors are usually low-cost, suitable for small-scale production and start-ups, and reduce investment risks.

5. Strong adaptability: It can handle a variety of materials, including small and lightweight items, suitable for different industries and application scenarios.

6. Improve efficiency: Despite its small size, small belt conveyors can effectively improve the speed and efficiency of material transportation and optimize production processes.

7. Automation integration: It can be seamlessly connected with other small automation equipment (such as sorting machines and packaging machines) to improve the overall automation level.

Available Options

According to different conveying requirements, small belt conveyors can be customized in many ways, mainly including the following aspects:

1. Conveyor belt material

Ordinary PVC conveyor belt: Suitable for conveying general materials.

High temperature resistant conveyor belt: Suitable for conveying materials in high temperature environment.

Wear-resistant conveyor belt: Suitable for conveying materials with high wear.

Food grade conveyor belt: Suitable for the food industry and meets food hygiene standards.

2. Frame material

Carbon steel: Economical and durable, suitable for general environment.

Stainless steel: Corrosion resistant, suitable for humid or corrosive environment.

Aluminum alloy: Lightweight and high strength, suitable for equipment that needs to be moved.

3. Drive mode

Motor drive: The motor drives the roller to drive the conveyor belt to run.

Pneumatic drive: Use compressed air to drive the conveyor belt, suitable for clean environment.

5. Conveyor belt type

Flat belt: Used to convey flat materials.

V-belt: Used to convey round materials.

Mesh belt: Used to convey small items or bulk materials.

Solutions by Industry

-

Small belt conveyor for dirt

A horticultural company, focusing on plant breeding and soil processing, needed an efficient conveying system to transport the soil from the mixing area to the packaging area. The customized small belt conveyor transported the soil at a speed of 500 kg per hour, reducing manual handling and improving production efficiency.

-

Small belt conveyor for bagged flour

A large flour processing factory produces many types of flour. Bags of flour need to be transported from the production line to the storage area to improve the level of automation. The small belt conveyor can transport 300 bags of flour per hour, significantly reducing labor costs. Improved warehousing efficiency.

-

Small belt conveyor for electronic components

An electronic equipment manufacturer, focusing on the production and assembly of small electronic components, needs a precise conveying system to transport small electronic components from the assembly area to the testing area. The small belt conveyor uses anti-static material and is configured with a precise conveying speed to ensure the safety of the components.