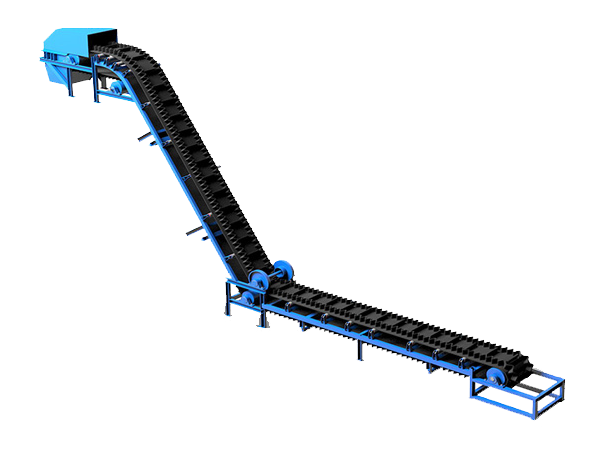

Adjustable Belt Conveyor

Adjustable height, the height of the lift can be adjusted according to the height of the silo or truck

Conveying length: 5-20 meters

Conveying capacity: 160 cubic meters per hour

Adjustable height: 1.7-6 meters

Introduction of Adjustable Belt Conveyor

Adjustable belt conveyor is equipped with a lifting device, which can control its end height at any time. According to your needs, the lifting device can be designed as automatic or manual. The automatic type is more convenient, fast and labor-saving, and the manual type requires a lower budget.There are 5 meters, 8 meters, 10 meters, 12 meters, 15 meters, 18 meters, 20 meters and other specifications. It can move freely and flexibly, and it can be installed on both sides of the rack. There is a side pipe to prevent the material from falling off during transportation, and there are adjustment handles on both sides of the feeding hopper to support the side plate to prevent the material from spilling, which is convenient for the transportation of bulk materials.

Lifting height of 6 meters: 1.7-2.7 meters

Lifting height of 8 meters: 2.5-3.7 meters

Lifting height of 10 meters: 2-4 meters

Lifting height of 12 meters: 2-4.5 meters

Lifting height of 15 meters: 3-6 meters

-

Adjustable Belt Conveyor

Adjustable Belt Conveyor

Video

Adjustable Belt Conveyor with ribs to transport grain

Removable trough Adjustable Belt Conveyor bagged feed truck

Features and Benefits

1. Height adjustable: You can adjust the button to control the length of the conveyor according to your own requirements. If the machine is equipped with a lift, you can also control its end height at any time. Loading and unloading can be done by simply pulling the cargo by the operator's side. The belt can be rotated forward for loading, and the belt can be reversed for unloading. Its processing efficiency can reach 30 pieces per minute, and the lifting height can reach 6 meters.

2. Reduce costs: greatly shorten the distance for manual material handling. It reduces laying time, labor intensity and cargo damage, thereby reducing handling costs and improving work efficiency.

3. Flexible collocation: it can be used in conjunction with feeding equipment, mixers, trucks and other conveying equipment to continuously and stably load and unload goods.

4. Operation safety: reduce accidents caused by excessive fatigue in manual loading and unloading of goods.

Structure of Adjustable Belt Conveyor

Adjustable belt conveyor is composed of main frame, walking wheel, universal wheel, lifting device and so on. Among them, the large frame of the fuselage is usually made of steel pipes to reduce its own weight and improve the mobility and lightness of the belt conveyor.

There are two types of lifting devices: manual and electric. The price of manual lifting is low, and the electric lifting is easier and more convenient.

Lifting device: its end height can be controlled at any time.

Technical Parameters

| Model |

Delivery volume (t/h) |

Bandwidth | Belt speed | Conveying length | Drum diameter | Ldler diameter | Belt length | Tail length | Lap gauge | Installed power |

| DSJ65/20/2×30 | 200 | 650 | 1.63 | 600 | φ450 | φ89 | 50 | 12 | 900 | 2×30 |

| DSJ65/20/2×37 | 200 | 650 | 1.63 | 800 | φ450 | φ89 | 50 | 12 | 900 | 2×37 |

| DSJ65/10/40 | 100 | 650 | 2 | 600 | φ500 | φ89 | 100 | 12 | 900 | 40 |

| DSJ65/20/2×40 | 200 | 650 | 2 | 800 | φ500 | φ89 | 100 | 12 | 900 | 2×40 |

| DSJ65/20/2×55 | 200 | 650 | 2 | 1200 | φ500 | φ89 | 100 | 12 | 900 | 2×55 |

| DSJ80/30/2×30 | 300 | 800 | 1.63 | 500 | φ450 | φ89 | 50 | 12 | 1100 | 2×30 |

| DSJ80/40/40 | 400 | 800 | 2 | 250 | φ500 | φ89 | 100 | 12 | 1100 | 40 |

| DSJ80/40/2×40 | 400 | 800 | 2 | 500 | φ500 | φ89 | 100 | 12 | 1100 | 2×40 |

| DSJ80/40/2×40P | 400 | 800 | 2 | 500 | φ500 | φ89 | 100 | 12 | 1100 | 2×40 |

| DSJ80/40/2×55 | 400 | 800 | 2 | 700 | φ500 | φ89 | 100 | 12 | 1100 | 2×55 |

| DSJ80/50/2×75 | 500 | 800 | 2 | 800 | φ500 | φ89 | 50 | 12 | 1100 | 2×75 |

| DSJ80/40/2×90 | 400 | 1200 | 2 | 1200 | φ630 | φ89 | 50 | 12 | 1100 | 2×90 |

| DSJ80/40/2×110 | 500 | 800 | 2 | 1400 | φ630 | φ89 | 100 | 15 | 1100 | 2×110 |

| DSJ100/63/2×75 | 630 | 1000 | 2 | 650 | φ630 | φ108 | 50 | 12 | 1362 | 2×75 |

| DSJ100/63/125 | 630 | 1000 | 2 | 500 | φ630 | φ108 | 100 | 15 | 1362 | 125 |

| DSJ100/80/2×125 | 800 | 1000 | 2 | 900 | φ1000 | φ108 | 100 | 15 | 1362 | 2×125 |

| DSJ100/80/132 | 800 | 1000 | 3 | 900 | φ100 | φ108 | 100 | 15 | 1362 | 2×132 |

| DSJ100/80/2×160 | 800 | 1000 | 3.15 | 1100 | φ1000 | φ133 | 100 | 15 | 1362 | 2×126 |

| DSJ100/80/2×200 | 800 | 1000 | 3.15 | 1300 | φ1000 | φ133 | 130 | 15 | 1362 | 2×200 |

| DSJ100/80/2×250 | 800 | 1000 | 3.15 | 1700 | φ1000 | φ133 | 130 | 15 | 1362 | 2×250 |

| DSJ120/100/2×75 | 1000 | 1200 | 2 | 600 | φ630 | φ108 | 50 | 15 | 1562 | 2×75 |

| DSJ120/180/2×200 | 1800 | 1200 | 3.3 | 650 | φ1080 | φ133 | 130 | 15 | 1562 | 2×200 |

| DSJ120/200/3×250 | 2000 | 1200 | 3.3 | 1100 | φ1080 | φ133 | 130 | 15 | 1562 | 3×250 |

| DSJ120/150/2×315 | 1500 | 1200 | 3.3 | 1200 | φ1080 | φ133 | 130 | 15 | 1562 | 2×315 |

Application

Adjustable belt conveyor is suitable for continuous or intermittent conveying of items below 100KG or powder and granular items. The height of the lift can be adjusted according to the height of the silo or truck. It is mainly used in loading, shipping, reloading or stacking various bulk materials The bulk density at room temperature is 500~2500kg/m3 of various bulk materials or articles. The materials are transported by a single or multi-machine combined transportation system, which can be arranged in a horizontal or inclined form according to the process requirements.

In addition to meeting the requirements of horizontal or inclined conveying, it can also adopt a conveying form with a combination of convex arc sections, concave arc sections and straight sections. The block size of the material that the conveyor allows to convey depends on the bandwidth, belt speed, groove angle and inclination angle, and also Depends on how often the chunks appear.

Solutions by Industry

Application of two common scenarios

1. Adjustable Belt Conveyor is used for grain or cargo loading

As you can actually see, the carriages often have different heights. The purpose of the Adjustable Belt Conveyor is that it can be adjusted according to different carriage heights, making it more widely applicable.

2. Adjustable Belt Conveyor is used for palletizing bags and haystacks

The height of cartons, bags and haystacks will undoubtedly continue to change and increase with accumulation. At this time, the function of Adjustable Belt Conveyor is to adjust the height at any time to reduce the labor intensity during work.