Belt Conveyors System

Used to transport materials or goods from one point to another within a manufacturing or distribution facility.

Belt width: 400-2400mm

length: 3-30 meters (extended and customizable)

Conveying speed: 1.25-2.0m/s

Belt material: PVC/rubber

Conveying capacity: 30-100 t/h

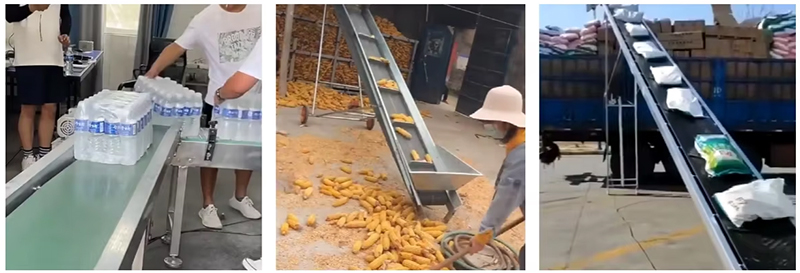

Application: Ports, docks, stations, coal yards, warehouses, construction sites, gravel yards, farms, etc., suitable for short-distance conveying and loading and unloading of bulk materials or single-piece items weighing less than 100kg.

-

Introduction of Belt Conveyors System

The belt conveyor system mainly uses the continuous or intermittent motion of the conveyor belt to transport various items of different weights.The belt conveying system can be designed in various ways, such as horizontal, inclined or vertical, turning; adding ribs to prevent falling to convey bulk materials, and can also convey various cartons, packaging products and other goods, with a wide range of types and applications.The function of the conveyor belt is to move objects from point A to point B with minimal effort.

What is the Function of Belt Conveyor System?

Material Transportation:

Bulk Materials: Conveying large quantities of materials like coal, ore, or grain.

Packaged Goods: Transporting boxes, cartons, or pallets.

Individual Items: Moving discrete items like bottles, cans, or manufactured parts.

Process Integration:

Assembly Lines: Moving components along assembly lines for various manufacturing processes.

Packaging Lines: Transporting products to packaging stations.

Inspection Stations: Conveying products to quality control points.

Material Handling:

Loading and Unloading: Facilitating the loading and unloading of materials from vehicles or storage areas.

Sorting and Distribution: Sorting and directing materials to specific locations.

Product Types of Belt Conveyors System

Features: Mainly used for conveying various bulk materials, packages or finished items in the horizontal direction.

Purpose: Suitable for horizontal or slightly inclined conveying, and can convey various granular, blocky and powdery materials.

Features: The 3-stage retractable belt (3-26m) can penetrate deep into the interior of the carriage, and the height can be adjusted to match the handling

Application: For loading and unloading of container trucks. Widely used in bagged products, logistics distribution centers, express tire handling and other industries.

Features: Movable, lightweight, with baffles, lower cost

Uses: It is used for loading, unloading and transshipment of bulk materials and packaging of wheat, corn, soybeans and other grain crops.

Features: Its design features vertical baffles on the belt surface, which helps to transport materials at various angles, especially bulk or loose items, without slipping back.

Purpose: Suitable for a variety of materials, including bulk items, packaged goods and loose products.

Features and Benefits

1. Simple structure, easy maintenance, low energy consumption and low use cost.

2. It can realize multi-point loading and multi-point unloading.

3. Low noise, suitable for occasions where the working environment is relatively quiet.

4. The main components are interchangeable and versatile.

5. The conveying is stable and reliable, and there is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed material.

6. The conveying capacity is strong, the conveying distance is long, and the operation is reliable, and it is easy to realize automation and centralized control.

7. The conveying range is wide, which can continuously convey wet, dry, powdery and bulk materials and finished items.

8. Equipment with special requirements for heat resistance, cold resistance, waterproof, anti-corrosion, explosion-proof, flame retardant, etc. can be customized according to different conveying processes and working environments.

Belt Conveyors System Structure

Frame: The structural backbone of the conveyor, providing support for the belt and other components.

Belt: The flexible material that carries the material to be transported. It can be made of rubber, PVC, or other durable materials.

Drive Pulley: Powered by a motor, this pulley drives the belt, propelling the material along the conveyor.

Idler Rollers: These support the belt and reduce friction, ensuring smooth operation.

Tensioning Device: Maintains proper belt tension, preventing slippage and ensuring optimal performance.

Motor and Gearbox: Provides the power to drive the conveyor system.

Technical Parameters of Belt Conveyors System

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Different types of conveyor belt options

The belt material of the belt conveyor system is a key factor affecting the performance and service life of the conveyor. Different conveying tasks have different requirements for belt materials, so choosing the right belt material is crucial.

Rubber belt: It has good elasticity, wear resistance and oil resistance, and is suitable for conveying general materials. It is widely used in mining, metallurgy, building materials and other industries.

PVC belt: It is acid-resistant, alkali-resistant, corrosion-resistant and oil-resistant. It is suitable for conveying in corrosive environments and is suitable for food, medicine, chemical and other industries.

PU belt: It is wear-resistant, oil-resistant and chemically resistant, and has good elasticity and cold resistance. It is widely used in electronics, food, medicine and other industries.

Cotton canvas belt: It is low-cost and easy to splice. It is mainly used for conveying light materials.

Principle of Belt Conveyor Systems

Material loading: The material is placed on the belt through the loading point (such as hopper, conveyor, etc.).

Starting the system: Start the motor and drive the belt to start moving.

Material transportation: The belt moves forward under the action of the drive wheel, and the material is transported with it.

Material distribution: The material is evenly distributed on the belt to ensure stability during transportation.

Arriving at the unloading point: The material reaches the predetermined unloading position and is unloaded from the belt by gravity or other means.

System stopping: After the transportation is completed, the motor is stopped and the belt stops moving.

Video

Grain belt conveyor for corn palletizing

PVC belt conveyor conveys capsules

Retractable Belt Conveyor for parcel loading

Climbing Belt Conveyor for garbage collection

Application

As an efficient and flexible material handling equipment, the belt conveyor system plays a vital role in modern industrial production. It is widely used in various production lines and logistics systems to achieve continuous and automatic transportation of materials.

| Industry | Application scenarios | Features |

| Food industry | Raw material transportation (grain, sugar), finished product transportation (packaged food) | Food grade material, high hygiene requirements |

| Energy industry | Coal transportation in thermal power plants, fuel transportation in nuclear power plants | High temperature resistance, wear resistance, dust resistance |

| Mining industry | Open-pit mining, underground mine transportation, material transportation in ore dressing plants | Large tonnage, long distance, wear resistance, corrosion resistance |

| Metallurgy industry | Raw material transportation (iron ore, coke), finished product transportation (steel plates, steel coils) | High temperature, high wear, large tonnage |

| Building materials industry | Cement production (raw materials, finished products), sand and gravel aggregate transportation | Large dust, high material density |

| Port logistics | Bulk cargo handling, container terminals | Large tonnage, fast loading and unloading |

| Chemical industry | Raw material transportation, finished product transportation | Corrosion resistance, explosion-proof |

| Logistics warehousing | Warehousing, outbound, sorting, distribution | Flexibility, high degree of automation |

| Electronics industry | Electronic component transportation, PCB board transportation | High precision, anti-static |

| Paper industry | Raw material transportation (wood pulp), finished product transportation (paper) | Wet environment, wear resistance |

| Wood processing industry | Log transportation, board transportation | Long-length material, wear resistance |

| Agriculture | Grain transportation, fruit and vegetable transportation | Easy to corrosion, strong seasonality |

| Waste disposal | Garbage transportation, sorting | Harsh environment, hygiene requirements |

Systematic Solution

Solutions by Industry

For bulk or packaged food, some medicine delivery

Recommended Belt Conveyors System: PVC belt conveyor

Features: safe and hygienic, in line with food safety standards, oil resistant, high and low temperature resistant, acid and alkali corrosion resistant

Conveying bulk or bagged grain, partial parcels

Recommended Belt Conveyors System: Grain Belt Conveyor/Troughed Belt Conveyor

Features: The structure is simple and light, can be operated by a single person, most of them are mobile design, the purchase cost is low, and it can save manpower input.

-

Climbing Belt Conveyor is Conveying okra

-

Two Belt Conveyors are Conveying meat

-

Retractable Belt Conveyor is delivering boxes