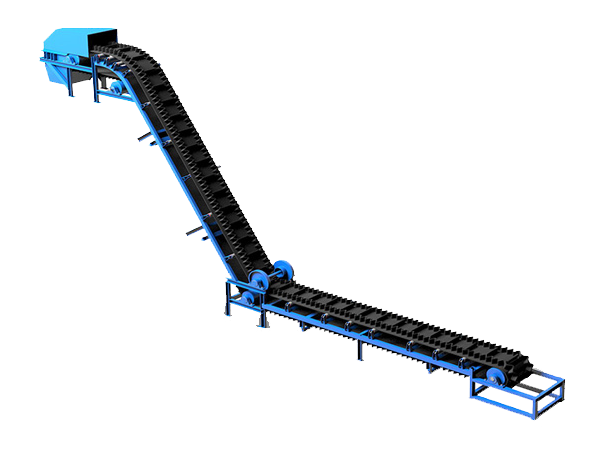

Climbing Belt Conveyor

The Climbing Belt Conveyor can realize the transportation of goods such as climbing slopes, mezzanines, and overhead equipment within an inclination angle of 30°-90°.

Belt width: 20-2000mm

Belt material: rubber belt, PVC belt, canvas belt, food belt, etc.

Conveying speed: 0.1-10M/min

Conveying capacity: 428m3/h

Conveying height: 500m

Tilt angle: 30°-90°

Introduction of Climbing Belt Conveyor

The Climbing Belt Conveyor can realize the transportation of bulk materials, packages or irregular-shaped materials at any inclination angle of 30°-90°, and realize the continuous transportation of goods between floors or height differences. The belt is designed with unique partitions and ribs to create conditions for the realization of large inclined angle conveying.

Climbing belt conveyor has a maximum load-bearing capacity of 60kg and a height of 500mm. It is generally suitable for loading and unloading of various models. The belt can run forward and reverse, the belt drive speed is adjustable, up to 36m/min, with a universal wheel, movable.

Climbing Belt Conveyor Options

1.Ordinary plane belt Climbing Belt Conveyor

It is usually used at home, and it is undoubtedly a good helper for grain grain loading and storage or other goods handling, which can greatly reduce your work intensity.

2. Climbing Belt Conveyor with black non-slip pattern

It is more suitable for transporting large-volume products such as parcels, cartons, and bags. It is usually foldable and liftable to easily adapt to height changes.

3. Climbing Belt Conveyor

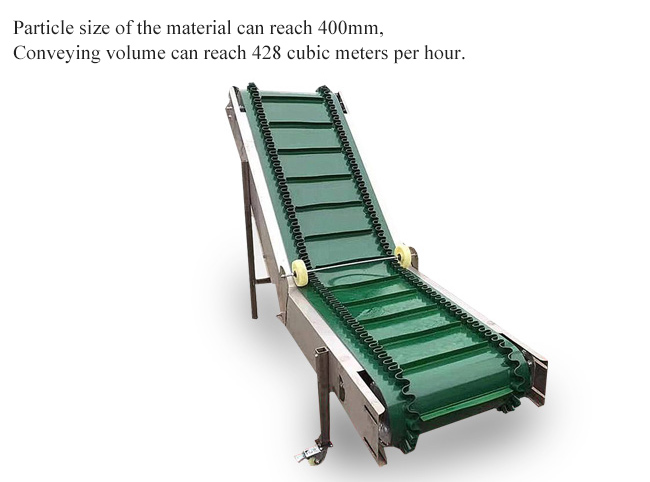

The design of the belt surface partition and sidewall is usually used to convey granular bulk materials, such as candy, fruit, etc., and is mostly used in food processing plants.

Belt width: Usually the width is 20-2000mm. Can also be customized according to customer requirements.

Belt rack material: carbon steel, stainless steel, aluminum profiles.

Conveyor belt material: PVC belt, rubber belt, plastic belt, canvas belt.

The conveying speed is generally 0.1-10M/min, which can also be adjusted or fixed according to user needs.

The belt drive modes are: geared motor drive, electric drum drive.

Belt conveyor speed regulation mode: frequency conversion speed regulation, stepless speed change.

special design

Layout of Climbing Belt Conveyo

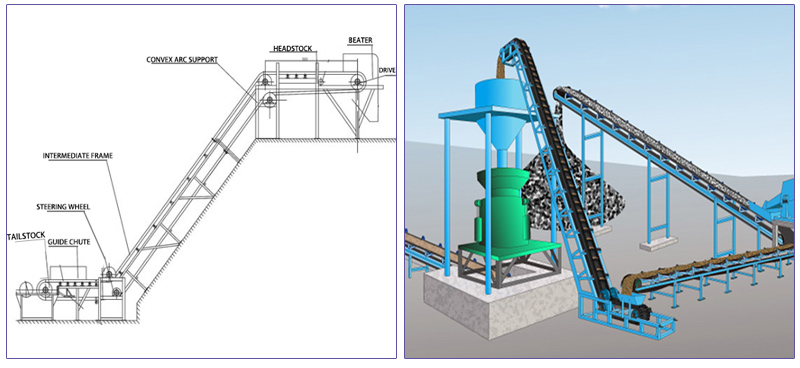

The layout of the Climbing Belt Conveyor mainly includes 4 layout forms: inclined, lower end horizontal-inclined, inclined-upper horizontal, and Z-shaped.

1、Inclined Belt Conveyor with Inclined Faces Only:The most common type of Inclined Belt Conveyor is usually used independently for household or small-volume material transportation, with the lowest cost budget.

2、Inclined Belt Conveyor with Horizontal Feed End:Increase the reserved space at the horizontal feeding end, usually used with feeding equipment such as screw feeder or vibrating feeder at the feeding end, and multiple feeding equipment can be placed.

3、Inclined Belt Conveyor with Horizontal Discharge End:Increase the reserved space at the horizontal discharge end, usually used in conjunction with packaging machines, screening machines or other conveying equipment, to fill the conveying gap between the lower end machines.

According to the unloading requirements of different heights, the height of the head frame used is different, and the legs of the middle frame should be matched according to the head frame. For example, a low-profile convex section frame with low-profile center frame legs. (head frame height H0=1000mm); Chinese-style convex arc cross-section frame is equipped with Chinese-style middle frame legs (head frame height H0=1100~1500mm); high-type convex arc cross-section frame is equipped with high-type middle frame legs (head frame The height is 1600~2000mm). Materials can transition smoothly through the convex arc section, reducing the loss of the climbing belt conveyor.

4、Z-Type Inclined Belt Conveyor:The shape of the machine is similar to the letter "Z", and it is usually used in the production line of a food processing factory, and it is used with the feeding system and the packaging processing system.

Application

The climbing belt conveyor can be used for feeding and discharging of almost all kinds of bulk materials. It can transport bags or bulk goods in the working environment of -15°C--+40°C, and the conveying angle can be from 30° to 90°. It can be used in food, agriculture, medicine, chemical industry, logistics and other industries to lift materials from low to high, such as snack food, frozen food, vegetables, fruits, grains, capsules, chemical raw materials, feed and other granular products, etc. It can also transport packaging products such as cartons, parcels, drums, etc.

Features and Benefits

1. It can transport all kinds of bulk materials or packaged goods. The partitions and ribs on the surface of the belt prevent the items from falling when conveyed on a large slope.

2. The conveying inclination is in the range of 0°-90°. When the material is conveyed vertically, the particle size of the material can reach 400mm, and the conveying volume can reach 428 cubic meters per hour.

3. It can be designed as a mobile type according to the customer's on-site requirements, and can also be transported by a single unit or multiple units according to different conveying process requirements;

4. There is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed material.

5. The length, width, height and angle of inclination of the conveyor can be selected according to customer needs.

Video

Technical Parameters

| Belt Width | 600mm |

| Belt Type | 5mm thick rough top green PVC belt |

| Adjustable Height | 850-2320mm |

| Adjustable Speed | 10-20m/min |

| Load Capacity | 50kg/m |

| Belt Driven Motor | 1.5kw |

| Hydraulic Power Pack | 1.5kw, Hydro-tek |

| Frequency Inverter | Delta |

| Main Electric Elements | Schneider |

| Caster | 200mm heavy duty lockable swivel PU casters |

| Frame Construction | Carbon steel, powder coated in BLUE RAL 5015 |

| Power Supply | 220V, single phase,50Hz/380V,three phase,50Hz |

Structure of Climbing Belt Conveyor

Climbing belt conveyor is mainly composed of head frame, pinch pulley, drive roller, corrugated conveyor belt and other components.

Conveyor length: generally 1m, 2m, 3m, 4m, 6m, 10m, other sizes can be customized.

Belt wire rack material: carbon steel, stainless steel, aluminum profiles.

Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE, PU belts, and anti-static belts are also available.

Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Bar skirt: optional heights of 20mm, 30mm, 40mm, 50mm, 60mm, etc.

Bar spacing: 100mm-1000mm range, other sizes can also be customized.

The conveying speed is generally: 0.1 ~ 10M/min, and can also be adjusted or fixed according to user needs.

Solutions by Industry

-

Climbing Belt Conveyor with Vibrating Feeder to transport materials upstairs

Slope: 80°

-

Climbing Belt Conveyor with horizontal belt conveyor to complete continuous conveying work

Slope: 45°

-

Small Climbing Belt Conveyor with mixer for material mixing

Slope: 50°

-

Climbing Belt Conveyor used with silo and mixer in chemical plant

Slope: 70°

-

Two Climbing Belt Conveyor Inclined Feed Conveyor

Slope: 45°, 55°

-

In the factory, the Climbing Belt Conveyor in a variety of inclination angles and designs is used with

Slope: able to adapt to all angles of production