Conveyors Belt

Consist of a continuous loop of material that rotates around two or more pulleys to move goods from one location to another.

Belt width: 400-2400mm

Conveying capacity: 40~1280 cubic meters per hour

Conveying speed: 1.3~2.0 m/s

Belt material: various materials such as rubber, PVC, PU, nylon or metal

Application: used in industries such as manufacturing, food processing, logistics, mining, agriculture and airports to transport raw materials, finished products, luggage and parcels.

Introduction of Conveyors Belt

Conveyor belts are essential components in various industries for efficient material handling and transportation. These belts consist of a continuous loop of material that rotates around two or more pulleys to move goods from one location to another.

Conveyor belts are widely used in various industrial fields, including mining, construction, metallurgy, chemical industry, grain processing, etc., for conveying raw materials, finished products, waste materials and other materials. According to the conveyor belt, there are rubber belts, plastic belts, and steel belts. According to the supporting structure, there are fixed and mobile types.

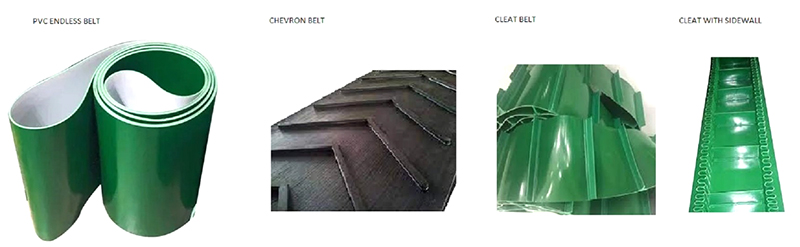

Product Display

Types of Conveyors Belts

Conveyors Belt is the general name of all belt conveyors, which are designed differently according to the conveying situation and have different characteristics and advantages.

1、Cleated Belt Conveyor

Add baffles on the sides of the conveyor belt and on the conveyor belt. Baffle prevents material from slipping during conveying.

2、Mobile Conveyor Belt

Install Brakeable Swivel Wheels. Easy to move and adapt to changes in the production site scene.

3、Z Type Belt Conveyor

"z" letter shape with added baffles and upper and lower horizontal sections. While lifting and transporting materials, it can better cooperate with other conveying equipment.

4、Retractable Belt Conveyor

Freely retractable multi-segment belt conveyor. Freely change the length according to the situation, and work flexibly.

Features and Benefits

1. It can realize 0-90° inclined conveying, the conventional conveying distance can reach 15 meters, supports customization, and the conveying capacity can reach 1280 cubic meters per hour.

2. According to the situation of the conveying site, there are two types of support structures: fixed type and mobile type. According to different conveying materials, the conveyor belt is divided into tape, plastic belt and steel core belt.

3. According to the requirements of the process flow, the material can be received at a single point or at multiple points, and it can also be discharged to multiple points or several sections.

4. Accessories such as ribs and skirts can be added according to user requirements to meet various process requirements.

5. The maintenance and replacement of smaller parts can be completed quickly on site, and the maintenance cost is low.

Video

Technical Parameters

| Project | DY5051 | DY5071 | DY50101 | DY50102 | DY50102A | DY50151 | DY50152 | DY50152A | |

| Captain(m) | 5 | 7 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Bandwidth(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Belt speed(m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| *large conveying height(m) | 1.63 | 1.59 | 1.77 | 4.52 | 4.52 | 1.61 | 6.32 | 6.32 | |

| Delivery capacity | m3>h | 160 | 160 | 160 | 125 | 125 | 160 | 125 | 125 |

| /h | 145 | 145 | 145 | 112 | 112 | 145 | 112 | 112 | |

| Tilt angle (degrees) | 13°59′ | 9°16′ | 6.5° | 10°~>22° | 10°~22° | 3.81° | 10°~22° | 10°~22° | |

| Electric drum | Model | DY1.4 | DY1.4 | DY1.4 | DY1.5 | DY1.3 | DY1.4 | DY1.6 | DY1.3 |

| Power KW | 2.2 | 2.2 | 2.2 | 3.0 | 1.1 | 2.2 | 4.0 | 1.1 | |

| Gross weight(kg) | 518 | 604 | 892 | 1126 | 1071 | 1225 | 1491 | 1491 | |

The conveyors belt produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Structure of the Conveyors Belt

Belt: The continuous loop of material that carries the load.

Pulleys: Drive the belt and guide its movement.

Idlers: Support the belt and reduce friction.

Frame: Provides structural support for the entire system.

Drive Motor: Powers the system.

Belt Tensioning System: Maintains proper belt tension.

| Product | PVC belt |

| Model | B-500 |

| Material | Polyvinyl Chloride |

| Color | Green, white, black, blue & red |

| Thickness | 1mm-8mm |

| Pattern | Smooth, matt |

Special Customization of Conveyors Belt

1. Trough conveyor belt: 2-3 upper rollers are used to form a V-shaped trough body, so that the conveyor belt runs in the rolling V-shaped trough body, and guide trough guards are installed on both sides of the belt to ensure that bulk materials will not fall to both sides of the conveyor belt during transportation. It is suitable for horizontal or climbing transportation of bulk and bagged materials in industries such as domestic waste, kitchen waste, waste plastics, chemicals, and food.

2. Skirt conveyor belt: Adding accessories such as lifting baffles and skirts to ordinary belt conveyor belts can meet the lifting process requirements of particles and powders.

3. Lifting conveyor belt: It can not only realize the horizontal transportation of materials, but also change the height of the conveyor belt through the lifting mechanism to realize the lifting or lowering of materials. This kind of conveyor is widely used in production lines, especially in situations where materials need to be transported in multiple layers or vertically.

4. Curved conveyor belt: Its conveyor belt is not a straight line, but a certain arc, which can realize the curved movement of materials in the horizontal plane. This type of conveyor plays an important role in the layout of the production line, especially when it is necessary to change the conveying direction or achieve a compact layout.

5. Double-wing hydraulic lifting conveyor belt: It combines the continuous conveying capacity of the belt conveyor and the height adjustment function of the hydraulic lifting platform, and can realize the flexible conveying of materials in the horizontal and vertical directions.

6. Enclosed conveyor belt: Its conveyor belt is completely wrapped in a closed shell, with better sealing, which can effectively prevent material leakage and dust flying, and can also reduce noise and improve the working environment.

Conveyors Belt Material

Conveyor belts are made from a variety of materials, and the choice of material depends on the specific requirements of the application. Here are some common materials used when manufacturing conveyor belts:

Rubber: Abrasion resistance, flexibility, and durability make it suitable for a variety of applications from general material handling to heavy industrial use.

PVC (Polyvinyl Chloride): Resistant to chemicals, oils, and abrasion, it is often used in industries where hygiene and cleanliness are important, such as food processing and pharmaceuticals.

PU (Polyurethane): It has strong resistance to oils, greases, and abrasion, and is often used in applications that require resistance to cuts and tears, such as the recycling and wood industries.

Nylon: High strength and durability, suitable for heavy-duty applications in industries such as mining, construction, and agriculture.

Metal: Made of stainless steel, it is used in high-temperature applications such as ovens, industrial furnaces, and cooling and freezing processes in the food industry.

Cotton or fabric: Lightweight and flexible, suitable for conveying lightweight materials. They are often used in industries such as packaging and textiles.

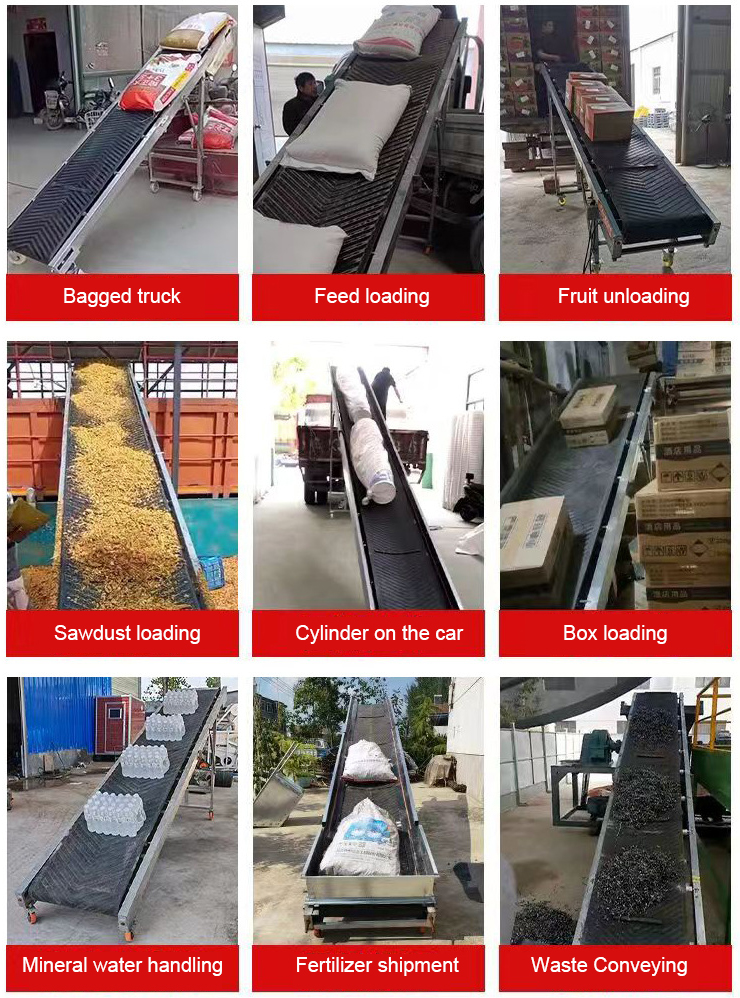

Application

Where can the Conveyors Belt be used? My answer is everywhere. They're versatile and adaptable, and their simple construction and rock-bottom price point allow Conveyors Belt to go from high-end factories making chips to delivering waste at waste disposal stations. Conveyors Belt not only improves work efficiency but also saves labor costs. The following are just some examples of the use of some industries and products, I hope to help you:

1. Logistics center: handling express boxes, woven bags, parcels; express loading and unloading, etc.

2. Mine: conveying bulk ore, coal, sand, stone, etc.

3. Farm: conveying haystacks, straw, agricultural and sideline products, grains, etc.

4. Food processing plants: conveying beverages, biscuits, potato chips, fruits, nuts, etc.

5. Airport baggage check and security check

Conveyors Belt can form the production line of the factory together with pallet conveyors, roller conveyors, packaging machines, etc.

Solutions by Industry

Here are three customer cases of conveyor belts:

-

A manufacturing company producing auto parts needed to increase efficiency and reduce manual labor in the production process. They installed a conveyor belt system that automatically transports parts between different stages of the production process, reducing the need for manual handling and increasing productivity. The conveyor belt system is customized to meet the specific requirements of the production process and is equipped with sensors to monitor belt tension, speed and alignment.

-

A mining company that produces coal and other minerals that require material to be transported over long distances and on steep slopes. They installed an inclined belt conveyor system to transport the coal from the bottom of the mine to the top of the hill. The conveyor system is customized to handle the weight and size of the coal and is equipped with skid plates to prevent the coal from slipping during transport.

-

A retail company's distribution center needed to increase the efficiency of warehouse operations and reduce manual labor. They installed a conveyor belt system that automatically transports boxes and pallets between different areas of the facility, reducing the need for manual handling and increasing productivity. Conveyor belt systems are customized to meet the specific requirements of your facility and are equipped with safety features such as emergency stop switches and guardrails.

Conveyors Belt Manufacturers

Dahan conveyor belt manufacturer produces TD conveyor belt, tilt conveyor belt, mobile conveyor belt, telescopic conveyor belt, lifting conveyor belt, climbing conveyor belt, conveyor belt for mining and other equipment, with models of 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, etc., and can be specially designed according to user needs. The product stock is sufficient, and conventional models can be shipped within 7 days, with perfect pre-sales, in-sales and after-sales services.