Grain Belt Conveyor

Widely used on farms, grain elevators and storage facilities for transporting grains such as wheat, corn and soybeans.

Belt width: 400mm-2400mm

Length: 5-40 meters

Conveying capacity: 2-100 tons/hour

Application: Commonly used in agriculture, food processing plants, grain storage facilities and other industries that require efficient grain transportation

Introduction of Grain Belt Conveyor

Grain belt conveyor are specifically designed to transport a variety of grain types, including wheat, corn, soybeans, etc., on farms and grain processing plants, and can load grains onto trucks, trains and ships.

Grain conveyor belts are available in a variety of widths (e.g. 400mm-2400mm) and lengths to meet different operational needs. They can be configured for horizontal or inclined transport according to the layout of the facility and can handle different capacities, typically ranging from a few tons to hundreds of tons per hour.

Application

Grain belt conveyors are widely used in the grain industry. Their main function is to be used in the conveying, processing, storage and transportation of grain.

Field to granary: The harvested grain is directly conveyed from the harvester to the transport vehicle or granary via a belt conveyor.

Grain processing plant: The raw grain is conveyed from the storage area to the processing production line, such as wheat, corn, rice, etc.

Grain storage and outbound: The grain on the transport vehicle can be quickly unloaded into the granary and transported to different storage areas as needed. The stored grain can be directly conveyed to the packaging machine, milling machine and other equipment via a belt conveyor, or loaded and transported to the market.

Loading and unloading: The grain is conveyed from the warehouse to the transport vehicle, or the grain on the transport vehicle is unloaded into the warehouse.

Feed mill: It is used for the transportation and processing of grain products such as flour and feed.

Video

Grain Belt Conveyor Conveys Sand Stacks

Grain Belt Conveyor conveying bagged grain loading truck

Difference Between Grain Belt Conveyor and Other Grain Conveyor

Grain belt conveyors are a popular choice for efficient grain handling, but they're not the only option. Let's compare them to other common grain conveyor systems:

| Features | Grain belt conveyor | Grain screw conveyor | Grain bucket conveyor | Grain suction machine |

|

|

|

|

|

| Conveying method | Horizontal or inclined conveying | Horizontal, inclined or vertical conveying | Vertical conveying | Suction and conveying |

| Conveying speed | Medium speed | Adjustable speed | Higher speed | Adjustable speed |

| Applicable occasions | Grain harvesting, storage, and delivery, horizontal conveying of large and medium-sized grain warehouses | Grain metering, batching, lifting, powder material conveying | Vertical lifting of grain, high-density material conveying | Grain loading and storage |

| Safety | Higher | Higher | Higher | Higher |

| Installation flexibility | Lower | Higher | Higher | Higher |

| Footprint | Occupancy is large | Small footprint | Small footprint | Small footprint |

| Breakage rate | Minimum | Maximum | Minimum | Small |

| Cost | Lower | Lower | Higher | Minimum |

Features and Benefits

Strong applicability: Suitable for various types of grains, such as wheat, corn, rice, etc., as well as granular materials of different shapes and sizes.

Protecting grains: The loss and wear of grains can be reduced during transportation, protecting the quality of grains and ensuring product quality.

Adjustable height: With adjustable height and inclination to adapt to various layouts and loading and unloading requirements.

Safety functions: Safety functions such as emergency stop buttons, guards and sensors are usually integrated to ensure safe operation.

Capacity and speed: There are various sizes and capacities to handle different volumes of grains. The speed of the conveyor can also be adjusted to meet specific requirements.

Flexibility: It can be transported horizontally, inclined or vertically as required, suitable for a variety of process layouts and site conditions.

Versatility: Grain belt conveyors can be customized with features such as covers, side skirts and discharge chutes to adapt to different applications and environmental conditions.

Technical Parameters

| Project | DY5051 | DY5071 | DY50101 | DY50102 | DY50102A | DY50151 | DY50152 | DY50152A | |

| Captain(m) | 5 | 7 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Bandwidth(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Belt speed(m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| *large conveying height(m) | 1.63 | 1.59 | 1.77 | 4.52 | 4.52 | 1.61 | 6.32 | 6.32 | |

| Delivery capacity | m3>h | 160 | 160 | 160 | 125 | 125 | 160 | 125 | 125 |

| /h | 145 | 145 | 145 | 112 | 112 | 145 | 112 | 112 | |

| Tilt angle (degrees) | 13°59′ | 9°16′ | 6.5° | 10°~>22° | 10°~22° | 3.81° | 10°~22° | 10°~22° | |

| Electric drum | Model | DY1.4 | DY1.4 | DY1.4 | DY1.5 | DY1.3 | DY1.4 | DY1.6 | DY1.3 |

| Power KW | 2.2 | 2.2 | 2.2 | 3.0 | 1.1 | 2.2 | 4.0 | 1.1 | |

| Gross weight(kg) | 518 | 604 | 892 | 1126 | 1071 | 1225 | 1491 | 1491 | |

Options

Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE, PU belts, and anti-static belts are also available.

Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Bar skirt: optional heights of 20mm, 30mm, 40mm, 50mm, 60mm, etc.

Bar spacing: 100mm-1000mm range, other sizes can also be customized.

The conveying speed is generally: 0.1 ~ 10M/min; the speed can also be adjusted or fixed according to the needs of the user.

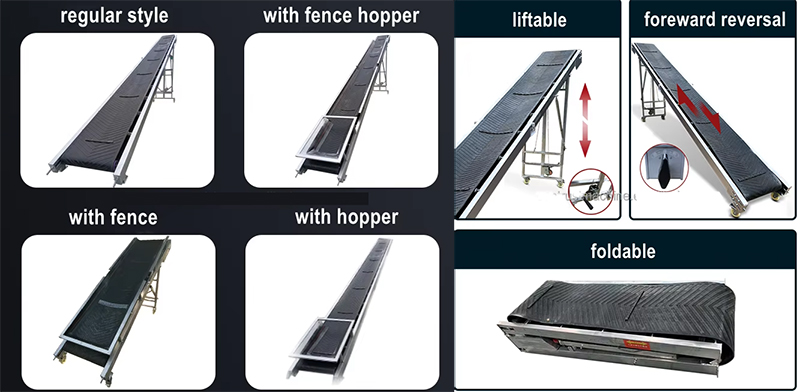

Grain Belt Conveyor Layout Forms

Grain belt conveyor layout forms are varied, and different layout forms are suitable for different working conditions and conveying requirements. Let us introduce several common layout forms in detail below:

1. Horizontal layout: The center lines of the rollers at the head and tail of the conveyor are on the same horizontal plane, which is suitable for conveying materials in the same height plane, such as conveying materials from one workstation to another in the production workshop of the factory; horizontal handling of goods in the logistics warehouse, etc.

2. Inclined layout: The center lines of the rollers at the head and tail of the conveyor are in the same inclination plane, which is suitable for lifting or lowering materials, such as lifting grain from the pit to the high-level silo, or from the high-level silo to the low-level equipment.

3. Vertical layout: The center lines of the rollers at the head and tail of the conveyor are in a vertical position, which is suitable for vertical lifting or lowering of materials, such as lifting grain from the pit to the high-level silo, or directly dropping from the high-level silo into the packaging machine.

4. Curved layout: The conveyor belt is curved, which is suitable for occasions with narrow space or the need to change the conveying direction, such as conveying around obstacles in the workshop, or conveying materials to equipment at different heights.

5. Combined layout: Combine multiple layout forms such as horizontal, inclined, and vertical to meet complex conveying process requirements. For example, in large grain warehouses or food processing plants, combined layout is often used to achieve multi-station and multi-level material transportation.

Solutions by Industry

-

Farm storage facility

Background: Customers need to efficiently store and transport harvested corn kernels on their farms.

Solution: Choose the B200 grain belt conveyor to quickly transport corn kernels from the harvester to the storage bin.

Effect: Customers reported that the transportation efficiency has been significantly improved, manpower has been saved, and work safety has been improved.

-

Wheat Processing Plant

Background: The client’s processing plant needs to transport wheat from the receiving area to the processing equipment.

Solution: Use B300 grain belt conveyor, designed to adapt to the characteristics of wheat and ensure smooth transportation.

Result: The overall efficiency of the production line has been improved, and the client said that the equipment runs stably and the maintenance cost is low.

-

Corn Harvesting and Processing Center

Background: The customer needs to process corn cobs of different specifications and requires high equipment flexibility.

Solution: Use B400 grain belt conveyor, which can quickly adapt to the transportation needs of different materials.

Effect: Reduced material loss, the customer is satisfied with the adaptability and efficiency of the equipment.