Mobile Conveyor Belt

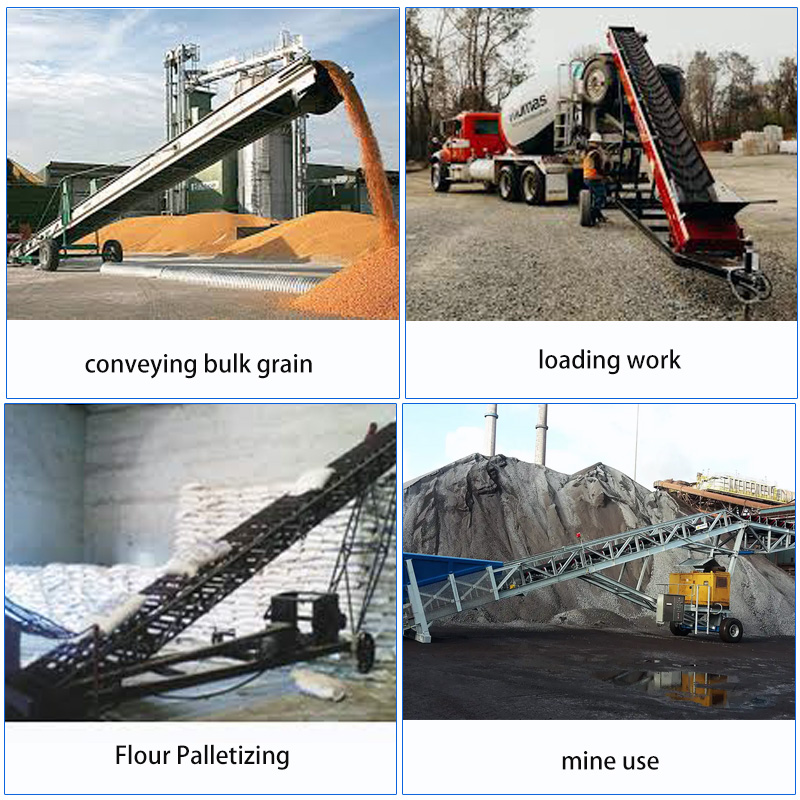

The perfect solution for mobile, temporary, short-term, and portable conveying, it can be used for conveying grains, terminals, express stations, small mines and other scenarios.

Length: 5-20 meters

Belt speed: 1.6m/s

Conveying capacity: 145t/h

It can move freely, and there are side conduits on both sides of the frame to prevent the material from falling off during transportation

The mobile conveyor belt is a conveyor system designed to be easily transported and relocated to different locations as needed, and is suitable for scenarios where the conveyor needs to be set up quickly and the conveyor site needs to be changed frequently. , mobile conveyor belts are commonly used in industries such as mining, quarrying, agriculture, construction and recycling, where materials need to be transported over short distances or between different processing points.

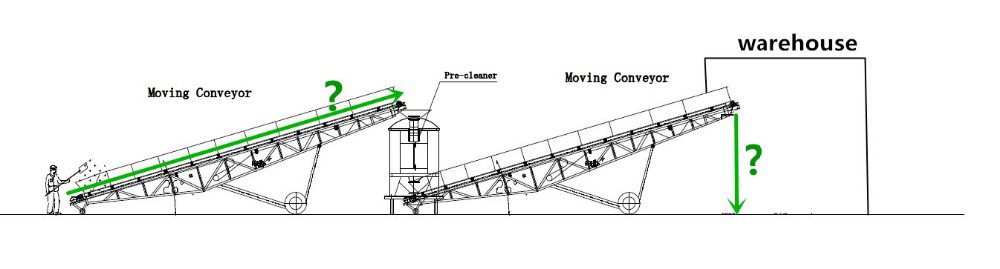

The mobile conveyor belt usually consists of a series of rubber belts or chains, which are mounted on a frame with wheels or tracks, so that the conveyor system can be easily moved from one location to another. There are 5 meters, 8 meters, 10 meters, 12 meters, 15 meters, 18 meters, 20 meters and other specifications. Side guides are provided on both sides of the frame to prevent material from falling off during transportation.

Features and Benefits

1. According to the different environment and conditions of use, moving wheels, pneumatic tires and sliding wheels can be installed at the bottom, which can be moved at will according to the stacking position of materials, and can be pushed into and out of the warehouse manually.

2. The mobile design is flexible and convenient, can be quickly arranged, and can be quickly folded after the conveying is completed, which is extremely suitable for the frequently changing on-site environment.

3. The conveying height of the Mobile Conveyor Belt is adjustable (1.7-6 meters adjustable), occupies a small space, and can be used in series with a variety of conveying equipment, mixing equipment and screening equipment.

4. The Mobile Conveyor Belt can carry bagged or bulk materials under 100kg, and the conveying capacity can reach 160t/h.

5. The type with the simplest structure in the conveying system, the floor area is relatively small, which can be reduced by more than 50%, and the product with the lowest price among the conveying equipment with the same conveying capacity.

Application

Mobile conveyor belt has practical applications in many industries, the following are some common practical application scenarios:

Mines: Used to transport bulk materials such as coal, ore and minerals from mining areas to processing plants.

Construction: Materials such as concrete, sand, bricks and construction waste can be transported from one construction site to another construction site or waste disposal station.

Agriculture: It is used to transport grain, seeds, fertilizers and other agricultural products, and plays an important role in agricultural production.

Logistics: used in logistics and distribution centers to transport goods from warehouses or loading stations to means of transport.

Recycling: Can be used to transport waste, used electronics and other recyclable materials from recycling sites to processing centers.

Food processing: Used for various transportation and conveying needs during food processing, such as conveying raw materials from one process to another, or conveying finished products from a processing line to a packaging area.

Video

Technical Parameters

|

Width (mm) |

Conveying length(m) Power(kw) |

Transfer speed (m/s) |

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

The mobile conveyor belt produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Structure of the Mobile Conveyor Belt

Mobile conveyor belt is composed of main frame, walking wheel, universal wheel, lifting device and so on. Among them, the large frame of the fuselage is usually made of steel pipes to reduce its own weight and improve the mobility and lightness of the belt conveyor. The lifting device is electric lifting, which reduces the danger and working intensity of manual lifting. The fixed universal wheel design provides convenient conditions for the movement of the Mobile conveyor belt.

Mobile Conveyor Belt different forms of mobile wheel selection

The key structure of the Mobile Conveyor Belt that can be flexibly and easily arranged lies in the design of the mobile wheels on the bracket, which provides the ability to reposition the Mobile Conveyor Belt when transporting in different scenarios. According to changes in actual usage, the choice of mobile wheels is also different.

1. Small universal wheels: used on small and medium-sized Mobile Conveyor Belts, which can be rotated and conveyed in any direction at 360°, with low purchase cost and easy replacement and maintenance.

2. Rubber pneumatic tires: Used in heavy-duty Mobile Conveyor Belt or when Mobile Conveyor Belt is used to transport heavy items, it can provide greater support for Mobile Conveyor Belt and avoid excessive pressure on unhardened ground. Causes the Mobile Conveyor Belt to sink into the ground.

Solutions by Industry

-

Construction Company

A construction company that needed a flexible and efficient way to transport construction materials such as sand, gravel and concrete between different job sites chose a mobile belt conveyor system consisting of a series of rubber belts mounted on a wheeled frame to help increase productivity and efficiency on the job site.

-

Farm

Farms require mobile conveyor systems to move feed and fertilizer between different areas of the farm. They opted for a mobile belt conveyor system that is mounted on a trailer and can be easily moved to different locations as needed. Conveyor systems help improve the efficiency of your farm.

-

Mining Company

A mining company needed a mobile conveyor system to transport ore and minerals from the mine to the processing plant. They opted for moving conveyor belts, a system mounted on tracks that move easily along the mine floor.