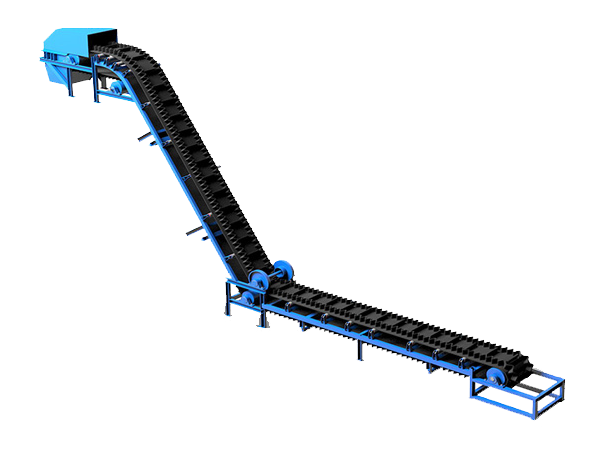

PVC Belt Conveyor

The conveyor belt is made of PVC material, which is suitable for conveying materials with a small load, mainly used in the food and packaging industries

Material: PVC

Running speed: 2-3m/s

Conveying distance: 1-20m

Conveying capacity: 4-1500m³/h

Power: 1.5-22kw

Introduction of PVC Belt Conveyor

PVC Belt Conveyor means that the material of the conveyor belt in contact with the material is food-grade polyurethane (PU), which meets food hygiene standards and can be in direct contact with food. The color of the belt is usually white or blue that matches the food or pharmaceutical industry, and has no peculiar smell. It has excellent water resistance, mildew resistance, oil resistance, acid and alkali resistance, and cutting resistance.

The carrying temperature of the PVC Belt Conveyor is -5°C~100°C, and -15°C~110°C for a short time. If there are special conveying requirements, such as conveying high temperature or extremely low temperature materials, special belt materials can also be selected.

Application

PVC Belt Conveyor is mostly used in light industries such as food, medicine, chemical industry, etc. PVC-coated conveyor belts are most suitable for material handling, bakery production applications and meat, fish and dairy products processing, and can be used in food processing plants, dessert production plants, vegetable distribution It can be used in scenarios such as picking, medicine lifting, and chemical conveying ingredients.

The temperature is required to be controlled between -40°C and 140°C, and it has the ability to resist hot water and steam, and generally resist oil and wear. According to different material processing and surface patterns, it can adapt to more production scenarios.

Features and Benefits

1. The conveying surface of the PVC belt is made of PU material that meets food hygiene standards, which is safe, oil-resistant and wear-resistant;

2. The PVC belt surface is designed with baffles and ribs, which can prevent the material from being scattered or slipped during the conveying process;

3. It has a wide range of conveying, and can convey various products in bulk, packaging, parcels and irregular shapes, with a conveying capacity of 4-1500m³/h, and a distance of 1-20m;

4. According to the actual needs, the PVC Belt Conveyor can be designed with additional silos, movable, foldable, and liftable.

Application video

PVC Belt Conveyor Conveying Nuts

PVC Belt Conveyor with Horizontal Conveyor Belt Conveying Sugar

Structure of PVC Belt Conveyor

PVC belt conveyor is mainly composed of frame, drive roller, redirecting roller, conveyor belt, tensioning device, driving device, idler and other parts.

Frame: Made of high-quality steel plate or aluminum plate, belt rollers and idlers are installed on the frame to drive and support the conveyor belt.

Drive roller: drive the conveyor belt to rotate, the drive roller is driven by a motor through a reducer, and the drive roller is generally installed at the discharge end, which can increase the traction force.

Reversing Roller: Change the running direction of the conveyor belt.

Conveyor belt: Made of PVC material, it mainly plays the role of carrying and transporting materials.

Tensioning device: make the conveyor belt generate a certain pre-tension to prevent the conveyor belt from slipping on the drive drum.

Idler: Support the conveyor belt so that the sag of the conveyor belt does not exceed the specified limit to ensure its smooth operation.

Options

1. Basic size: the length, width and height of the equipment, providing the conveying angle, etc.

2. Frame material: carbon steel spray/stainless steel/aluminum, usually choose carbon steel spray.

3. Conveying speed: V≤60 m/min, common speed is 3-~15m/min.

4. Conveyor belt material: PVC/PU/rubber belt, etc. By default, white PVC material is selected, whether to add baffles and skirts

5. Motor power: 0.2/0.4/0.75/1.5/2.2/3.7kw.

6. Power supply: AC220V/AC380V.

7. Diameter of driving roller: 38, 50, 76, 89, 120mm and so on.

8. Other accessories: whether to install guardrails on both sides, whether it is mobile, whether the speed is adjustable, whether it has lifting and lowering, other requirements, etc.

Technical Parameters

| bandwidthB(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying amountQ3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center heightH2/h(MM) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center heightH2/h(MM) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section belt heightH2/h(MM) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| Middle foot widthB2/h(MM) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidthB(mm) | 1000 | 1200 | 1400 | |||||||||||

| sidewall height(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying amountQ3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center heightH2/h(MM) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center heightH2/h(MM) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section belt heightH2/h(MM) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| Middle foot widthB2/h(MM) | 1440 | 1690 | 1890 | |||||||||||

Solutions by Industry

The excellent performance of PVC conveyor belts provides a wide range of possibilities for use, and because of its high strength, low elongation, and good temperature resistance, PVC light conveyor belts are widely used.

1. PVC Belt Conveyor is used for high temperature or low temperature food transportation

The conveyor belt made of PVC material for food has good characteristics of not melting at high temperature and not breaking at low temperature. It can transport food at a temperature of -15 degrees Celsius to 100 degrees Celsius. Moreover, the material itself is safe and non-toxic, and will not be harmful due to temperature changes. The substance precipitated.

2. PVC Belt Conveyor is used for watering vegetables and fruits conveying

In the workshop of a vegetable and fruit processing factory, the conveyor belt is an indispensable structure for conveying fruits and vegetables. It is generally used before or after cleaning the vegetables and fruits. A large amount of water is attached to the surface of the cleaned fruits and vegetables. The PVC conveyor belt is waterproof and oil-resistant, and you can choose a waterproof motor. Guarantee production safety and durability of the conveyor belt.

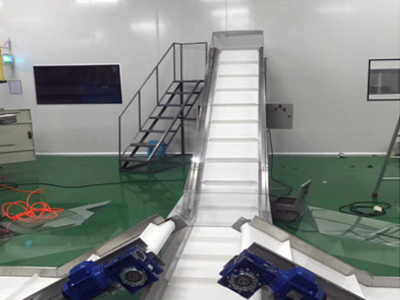

3. PVC Belt Conveyor is used for inclined lifting and conveying

The connection method of PVC conveyor belt is simple, usually using thermoplastic bonding or cold glue bonding, and steel buckle bonding can also be used. Therefore, in the case of inclined conveying bulk goods, you can choose ribs, baffles, and the combination of the two forms PVC conveyor belt to avoid slipping.

-

PVC Belt Conveyor with two belt conveyors for feeding

-

The PVC Belt Conveyor is directly conveyed upstairs through the passage

-

PVC Belt Conveyor with horizontal belt conveyor to transport dumplings

-

PVC Belt Conveyor Conveying Potatoes

-

Special Design PVC Belt Conveyor Conveying French Fries Upstairs

-

PVC Belt Conveyor with mixer to convey dough