Rubber Belt Conveyors

Configure the rubber belt according to the conveying material, wear-resistant, oil-resistant, grease-resistant, food-use, etc., for continuous or intermittent conveying of bulk or packaged products.

Conveying speed: 1.3-2.0m/s

Conveying length: 203m

Conveying capacity: 30~3000t/h

Introduction of Rubber Belt Conveyors

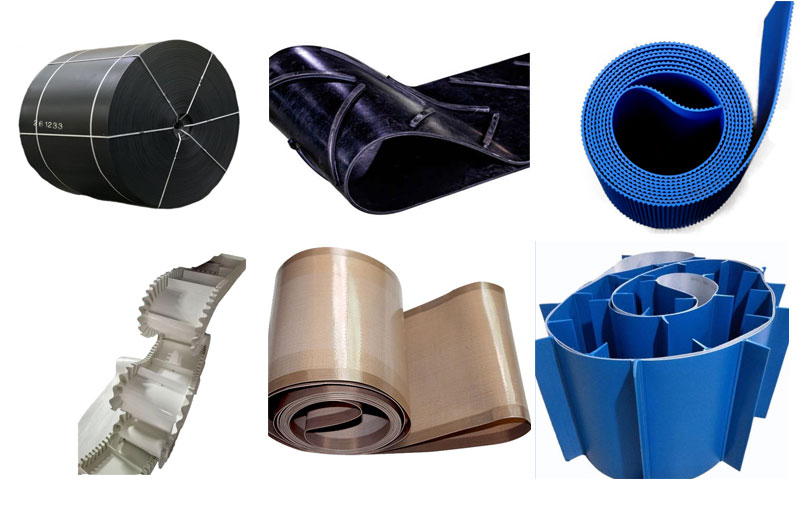

Rubber Belt Conveyors is different from other conveying equipment. It uses Rubber Belt to convey various products. According to different products, there are light Rubber Belt and Heavy Rubber Belt, which can be used in industries such as industry, agriculture, food, minerals or material recycling. Rubber Belt Conveyors have a variety of Rubber Belts to choose from, including widths, Rubber Belt constructions and profiles, such as Food Grade Rubber Belts, Wedge Rubber Belts, Sidewall Rubber Belts, Smooth Rubber Belts, and Patterned Rubber Belts.

Types of Rubber Belt Conveyors

Rubber belt conveyors have various structures, including groove belt conveyors, climbing belt conveyors, inclined belt conveyors and other forms.

Depending on the material being transported, Dahan Machinery equips its conveyors with various types of belts:

Criobelt: Conveyor belts are made of cut and abrasion resistant rubber with high resistance to atmospheric media, suitable for transporting abrasive, sharp, heavy, medium cold materials (-30° to + 90°C) and large sizes.

Termobelt: Conveyor belt with heat-resistant, abrasion-resistant, cut-resistant rubber outer layer, good resistance to atmospheric media, suitable for conveying abrasive, medium and large warm materials (110° to 130°C).

Actibelt: Conveyor belt with abrasion-resistant rubber cover, very resistant to highly aggressive substances, suitable for transporting chemically active cold materials (15° to 90° C), such as solvents, mineral oils, vegetable or animal oils and fats.

Spinabelt: Add abrasion-resistant cut-resistant rubber overlay, with V-shaped wedge surface, suitable for transporting cold bulk materials (-30° to +90° C) on steep slopes (30°/40°), abrasive Substances, medium and large, and even very heavy materials.

Boxbelt: Belt conveyors with various textures made of abrasion-resistant rubber for transporting material in packages (boxes, crates, packs, bags, etc.) in inclined sections.

special designs and designs

1. Suspension type: only used for special factory layout, limited to small belt conveyor system.

2. Movable: It is very convenient for frequent changes of transportation sites such as grain processing, wharf or loading and unloading.

3. Adjustable inclination height: suitable for situations where the conveying angle changes frequently or the conveying height is large.

4. Foldable: save the space occupied by the idle time of the conveyor, and facilitate the transportation of the machine.

5. Closed design: it is mostly used to transport powder or odorous materials to prevent dust or odor from escaping.

6. Increase the silo: increase the feeding volume at the feed end to increase the conveying output.

Different types of conveyor belt options

Conventional Rubber Conveyor Belt

The surface of the rubber conveyor belt is designed with V-shaped anti-slip patterns to provide additional friction for the conveyed materials

Conveyor belts for the food or pharmaceutical industry - hygienic

The rubber conveyor belt increases the design of sidewalls and baffles - avoiding the slipping and waste of materials in inclined conveying

Special material or coated rubber conveyor belt, high temperature, low temperature, oil resistance or corrosion resistance options

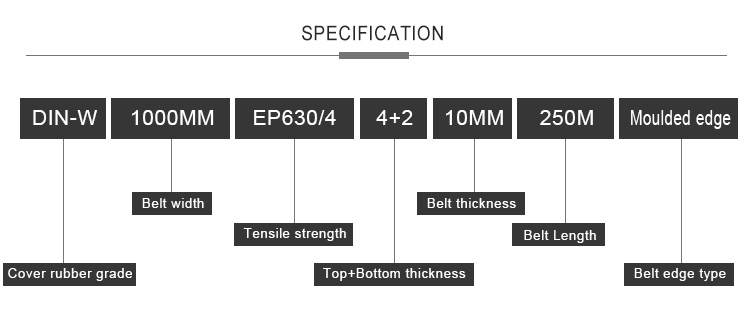

Rubber Belt Models for Regular Rubber Belt Conveyors

| Cover Rubber Grade | 8MPA,10MPA,12MPA,14MPA ,15MPA,17MPA,18MPA,20MPA,24MPA | DIN-ZDIN-N,DIN-D,DIN-W,DIN-Y,DIN-X,RMA-1,RMA-2,HR150°C,HR180°C,K, S, VT, MOR, OR |

|

Belt Width (mm) |

200,300,400,500,600.650,700,800,1000,1200,1400,1500,1600,1750,1800,2000,2200,2500 | 18",20",24",30",36",40",42",48",60",72",78",86",94" |

| Tensile Strength | CC56,TC70,EP100,EP125,EP150,EP200, EP250,EP300,EP350,EP400, | EP250/2 EP315/3,EP400/3,EP500/3,EP600/3,EP400/4,EP500/4,EP600/4,EP500/5,EP1000/5,EP1000/4,EP1250/5,EP600/6,EP1200/6 |

| Top+Bottom Thickness | 0+0,0.5+0.5,2+0,3+0,3+1.5, 4+2, 4+1.5, 4+3, 5+1.5,5+2,8+3, | 3/16"+1/16", 1/4"+1/16" |

| Belt Thickness | 6mm,7mm,8mm,9mm,10mm,12mm,15mm,20mm,25mm | |

| Belt Length | 10m,20m,50m,100m,200m,250m,300m,500m | |

| Belt Edge Type | moulded(sealed) edge or cut edge | |

video

Features and Benefits

1. The conveying material can range from fine powder to bulk ore, stone, coal or pulp wood, as well as conveying fine sieves or small droplets of fragile materials. Due to the high corrosion resistance of rubber conveyor belts, maintenance costs are relatively low when transporting strongly corroded or worn materials.

2. It can adapt to the slope transportation of 0-45°, while the truck transportation can only adapt to the original natural terrain of 6-8°.

3. The belt can be designed with anti-skid lines, ribs, baffles and other forms to enhance the friction of conveying materials and prevent slipping.

4. Compared with other transportation methods, rubber belt conveyors have high safety, low requirements for production personnel, and low probability of accidents. There will be no accidents caused by falling of bulky materials, crushing of people, or failure of large and heavy vehicles.

5. Among all the tools for transporting bulk materials, the man-hours and energy consumption per ton of belt conveyor systems for transporting bulk materials are generally lower. And with less time spent by maintenance crews, repairs and replacements of smaller parts can be done quickly in the field with low maintenance costs.

Structure of Rubber Belt Conveyors

Driving device: a device that transmits the torque of the motor to the belt to make the belt move continuously. It consists of a motor, a transmission roller, a coupling, a reducer, etc. With the improvement of the transport capacity of the conveyor and the lengthening of the transport distance, the power of the motor is increasing, and the multi-motor drive is also gradually increasing. With multi-motor transmission, the height and width of the transmission can be reduced.

Braking device: mainly refers to brakes and backstops. It is mainly used to prevent the rubber belt conveyors from reversing when the load is stopped. It causes the material to spill out (in severe cases, the belt will be broken or mechanically damaged). Generally, the inclination angle of rubber belt conveyors is used. When it exceeds 4-6 degrees, a braking device must be installed.

Supporting device: It refers to a series of equipment that carries tape and materials and completes the operation. The supporting device of the tape machine is mainly composed of an upper tip-shaped idler, a lower flat idler, a biasing and roughing, a buffer idler and a frame.

Tensioning device: Ensure that the tape has enough tension, so that the roller and the tape can generate the necessary friction, limit the sag of the tape between the brackets, and make the belt conveyor work normally.

Reversing device: It is mainly composed of reversing rollers, special brackets and pressing rollers.

Technical parameters

| Carrying roller form | Belt speed (m/s) | Bandwidth (mm) | |||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||

| Conveying capacity G (t/h) | |||||||

| Grooved idler | 0.8 | 78 | 131 | - | - | - | - |

| 1.0 | 97 | 164 | 278 | 435 | 655 | 891 | |

| 1.25 | 122 | 206 | 348 | 544 | 819 | 1115 | |

| 1.6 | 156 | 264 | 445 | 696 | 1048 | 1427 | |

| 2.0 | 191 | 323 | 546 | 853 | 1284 | 1748 | |

| 2.50 | 232 | 391 | 661 | 1033 | 1556 | 2118 | |

| 3.15 | - | - | 824 | 1233 | 1858 | 2528 | |

| 4.0 | - | - | - | - | 2202 | 2996 | |

| Parallel idler | 0.8 | 41 | 67 | 118 | - | - | - |

| 1.0 | 52 | 88 | 147 | 230 | 345 | 469 | |

| 1.25 | 66 | 110 | 184 | 288 | 432 | 588 | |

| 1.6 | 84 | 142 | 236 | 368 | 553 | 753 | |

| 2.0 | 103 | 174 | 289 | 451 | 677 | 922 | |

| 2.5 | 125 | 211 | 350 | 546 | 821 | 1117 | |

| Parallel idler | 10 meters | 15 meters |

| Belt width | 500-800(mm) | 500-800(mm) |

| conveyor belt speed | 0.8~1.6m/s | 0.8~1.6m/s |

| Delivery capacity(V=1.0m/s) | 70~278m3/h | 70~278m3/h |

| Rack Adjustment Inclination | 9°~20° | 9°~20° |

| Conveying large heights | 3910mm | 5700mm |

| Conveying small heights | 2000 | 2700mm |

| tension stroke | 300mm | 300mm |

| Motor Power | 2.2kw~5.5kw | 2.2kw~5.5kw |

| Transmission reduction ratio | 16.6 | 16.6 |

| wire ropeф12-6×19 | 17 meters | 26 meters |

| adhesive tape4(3+1.5) | 22 meters | 31.8 meters |

Application

Rubber belt conveyors are suitable for conveying powdery, granular, small block low-abrasive materials and bagged materials with a bulk density of less than 1.67/ton/cubic meter, such as coal, gravel, sand, cement, fertilizer, etc. , food, etc. The temperature of the material being sent is less than 60°C. According to the requirements of the conveying process, it can be conveyed by a single unit, or by multiple units or with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different layouts of the operation line.

Solutions by Industry