Troughed Belt Conveyor

U-shaped or V-shaped belt groove design keeps bulk materials such as coke, grain, sand and gravel in the center during transportation.

Conveying Angle: 0-25 degree

Belt Speed: 0.5-2m/s

Conveying capacity: ≤100kg

Introduction of Troughed Belt Conveyor

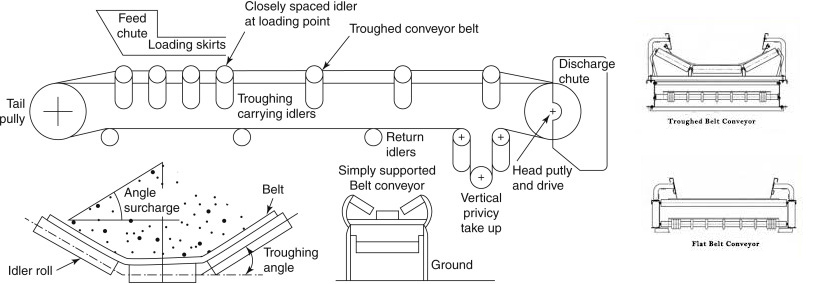

Troughed belt conveyors are where the belt forms a trough on the conveying side while running on idler rollers in 5-, 3- or 2-roller groups. The groove angles used are: 15°, 20°, 25°, 30°, 35°, 40°, 45°.

Trough belt conveyors are designed to help keep loose or bulk materials in the center of the conveyor. Belts come with rollers, guides or a sliding bed to which the belt conforms. Grooved belts are ideal for conveying loose or bulk materials, especially if the material is abrasive, but also for conveying over long distances while minimizing spillage.

Features and Benefits

1. The supporting industrial conveyor belt products have uniform force, low friction and long service life;

2. Compared with ordinary flat conveyor belts, the Troughed Belt Conveyor can accommodate more materials per unit length and is not easy to deviate and scatter.

3. The structure is simple, the inclined conveying within 25° can be realized, and the belt can be designed with anti-skid pattern.

4. It can turn in the horizontal plane with a certain curvature radius, which can realize the space curve conveying, and can reduce the transfer link, civil construction investment and operators, and improve the reliability of the conveying system.

Video

Structure of the Troughed Belt Conveyor

The special structure of the Troughed Belt Conveyor lies in the grooved belt conveying surface formed by him. The belt on the working surface is supported by a grooved roller frame composed of two or three rollers, and the return belt is supported by flat rollers.

As shown in the structure diagram, the combination of three rollers, the greater the inclination of the rollers on both sides, the larger the groove formed, and the depth of the groove determines the amount of material to be held to a certain extent. The horizontal roller in the middle is almost Withstands the full pressure from the conveyed material.

The design of the two rollers is only for small Troughed Belt Conveyor, and the conveying capacity and load-bearing capacity are relatively small.

Design features include:

At the same time, the Troughed Belt Conveyor is equipped with grooves to prevent belt deviation, parallel self-aligning rollers, spring cleaners and empty section cleaners, which can realize 25-degree inclined lifting and conveying.

Optional accessories for Troughed Belt Conveyor include feeding structure, reverse conveying, closed structure, folding design, etc.

Belt material selection: PVC, PU (food and medicine), rubber, special coating.

Belt drive mode: geared motor drive, electric drum drive.

Belt conveyor speed regulation mode: frequency conversion speed regulation, stepless speed change.

Belt frame material: carbon steel, stainless steel, aluminum profile.

AVAILABLE BULK HANDLING TROUGHED BELT CONVEYOR AND SYSTEMS

| Project | DY5051 | DY5071 | DY50101 | DY50102 | DY50102A | DY50151 | DY50152 | DY50152A | |

| Captain(m) | 5 | 7 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Bandwidth(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Belt speed(m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| *large conveying height(m) | 1.63 | 1.59 | 1.77 | 4.52 | 4.52 | 1.61 | 6.32 | 6.32 | |

| Delivery capacity | m3>h | 160 | 160 | 160 | 125 | 125 | 160 | 125 | 125 |

| /h | 145 | 145 | 145 | 112 | 112 | 145 | 112 | 112 | |

| Tilt angle (degrees) | 13°59′ | 9°16′ | 6.5° | 10°~>22° | 10°~22° | 3.81° | 10°~22° | 10°~22° | |

| Electric drum | Model | DY1.4 | DY1.4 | DY1.4 | DY1.5 | DY1.3 | DY1.4 | DY1.6 | DY1.3 |

| Power KW | 2.2 | 2.2 | 2.2 | 3.0 | 1.1 | 2.2 | 4.0 | 1.1 | |

| Gross weight(kg) | 518 | 604 | 892 | 1126 | 1071 | 1225 | 1491 | 1491 | |

Application

The Trough Belt Conveyor can be used for horizontal or inclined conveying within 25° of almost all bulk materials, such as:

Agriculture and feed industry transportation: corn, wheat, beans, rice, hay, feed raw materials

Recycling industry conveying: rubber granules, waste wood chips, paper scraps, plastic waste, recyclables

Wood industry: wood chips, woody biomass, small pieces, bark

Foundry, forging plant conveying: sand, ceramic particles, coal ash, limestone, ore, biomass

Solutions by Industry

-

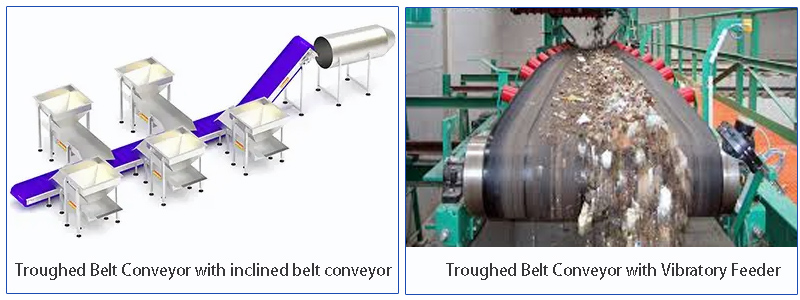

1、Trough Belt Conveyor Inclined Conveying of Chipped Wood Chips

-

2、Two Trough Belt Conveyors Conveying Bulk Candy in Tandem

-

3、Trough Belt Conveyors for dock loading and unloading

-

4、Trough Belt Conveyors Conveying Waste

-

5、Trough Belt Conveyors Conveying Grain