Z Type Belt Conveyor

The letter "Z"-shaped design, the upper and lower horizontal sections can better match the placement of the feeding and discharging equipment, and is used for continuous or intermittent conveying of powder and granular items at a large angle in the factory.

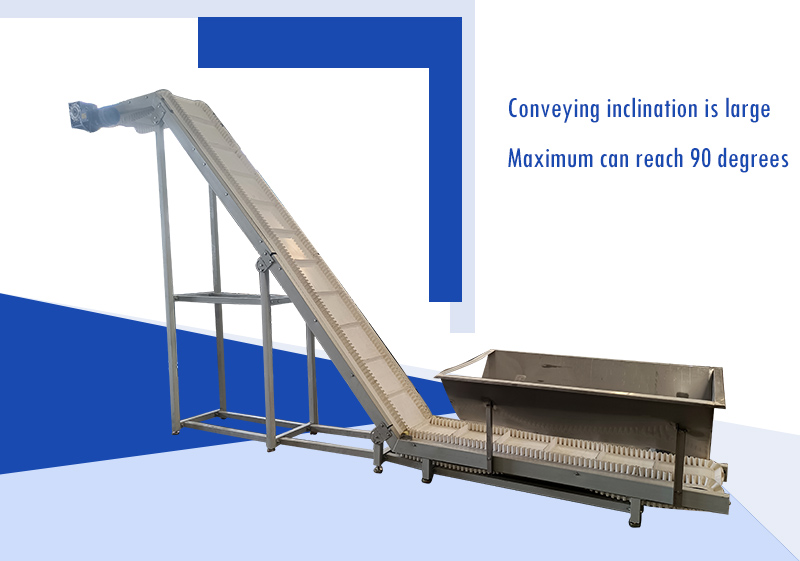

Conveying angle: ≤90 degrees

Conveying capacity: 428 cubic meters per hour

Conveying distance: 203 meters

Introduction of Z Type Belt Conveyor

The Z type belt conveyor is in the shape of the letter "Z". It is mainly composed of three parts: the lower horizontal section, the climbing section and the upper horizontal section. It is suitable for continuous transportation of goods between floors or height differences. The lower horizontal section of the Z Type Belt Conveyor can be equipped with a silo, with Vibratory Feeder, for quantitative and uniform feeding; the upper horizontal section can extend the discharge distance to better adapt to the distance between the conveyor and the silo, packaging machine or other conveying equipment the distance. Install strips, fixtures, skirts, etc. on the belt so that the objects can be lifted and conveyed at a larger angle. When conveying granular items, in order to prevent the items from rolling down due to gravity, you can add a piece at a certain distance.

Product Display

-

Z Type Belt Conveyor with vibrating feeder

-

Z Type Belt Conveyor with Linear Shaker

-

Z Type Belt Conveyor conveys bulk materials upstairs

-

Two Z Type Belt Conveyor for coordinating transportation

-

Z Type Belt Conveyor with packing machine

-

Z Type Belt Conveyor with silo

Application scenarios of Z Type Belt Conveyor

Z belt conveyors are suitable for a variety of scenarios involving the vertical or inclined transportation of products or materials. Here are some common application scenarios for Z-belt conveyors:

1. Food processing and packaging: used for vertical or inclined conveying of food during processing and packaging. They are used to transfer items such as snacks, baked goods, fruit, vegetables and frozen meals between different production levels or stages. Non-slip straps ensure safe, gentle handling of delicate foods.

2. Pharmaceutical and chemical industry: used for vertical conveying of materials such as powder, tablet, capsule and chemicals. They are used to transport these materials between different processing units, such as mixing, coating, drying and packaging equipment.

3. Recycling and waste management: used in recycling facilities and waste management centers for vertical transfer of recyclable materials. They help move materials such as plastic bottles, cans, paper and cardboard from one layer to another for sorting, processing or packaging.

4. Industrial manufacturing: suitable for various industrial manufacturing processes that require vertical or inclined transportation. They can be used to transfer assemblies, parts or products between different assembly stations, workstations or production levels.

5. Agriculture and planting: used to transport harvested crops, grains or seeds from ground storage to elevated storage silos or processing equipment. They facilitate the vertical transfer of materials, optimize storage capacity and simplify agricultural operations.

6. Material handling and logistics: Used in logistics centers, warehouses and distribution facilities for vertical transfer of items in packaging, palletizing and order fulfillment operations. They enable the efficient movement of goods between floors, reducing manual labor and improving operational efficiency.

Application video

Z Type Belt Conveyor with horizontal belt conveyor to convey candy

Z Type Belt Conveyor transports peanuts upstairs

Features and Benefits

1. It can be combined with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different layout types of operation lines.

2. The conveying inclination is large, and the maximum can reach 90 degrees. It is an ideal equipment for large inclination conveying and vertical conveying.

3. The conveying is stable, and there is no relative movement between the material and the conveyor belt, which can avoid damage to the conveyed material.

4. The Z Type Belt Conveyor can add a rib design to prevent bulk materials from falling when conveying at a large angle.

Technical Parameters

| bandwidthB(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying amountQ3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center heightH2/h(MM) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center heightH2/h(MM) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section belt heightH2/h(MM) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| Middle foot widthB2/h(MM) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidthB(mm) | 1000 | 1200 | 1400 | |||||||||||

| sidewall height(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying amountQ3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center heightH2/h(MM) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center heightH2/h(MM) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section belt heightH2/h(MM) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| Middle foot widthB2/h(MM) | 1440 | 1690 | 1890 | |||||||||||

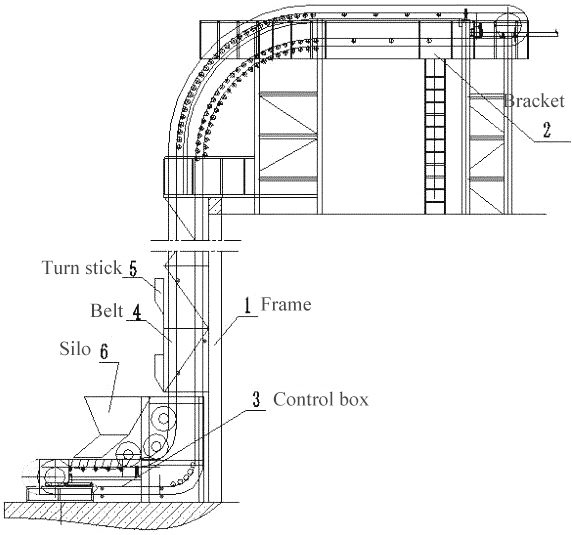

Structure of Z Type Belt Conveyor

Z type belt conveyor is composed of corrugated sidewall belt, base belt diaphragm, head drive roller, driving device, reversing pressure roller, sidewall roller, rapper and so on.

1. Upper horizontal section: In order to meet the requirements of different discharge heights, the head frame is divided into a low head frame, a Chinese head frame and a high head frame. And correspondingly, the upper horizontal section is equipped with low type convex arc section frame and low type middle frame support legs, middle type convex arc section frame and middle type middle frame support legs, high type convex arc section frame and high type. Type intermediate frame legs.

2. Inclined section: No matter whether the upper horizontal section adopts the low type, Chinese type, or high type intermediate frame legs, the inclined section adopts the low type intermediate frame legs. When the inclination of the conveyor is R45°, it is recommended to use type II low-type intermediate frame outriggers.

3. Lower horizontal section: The lower horizontal section adopts low-type intermediate frame legs.

Options

Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE, PU belts, and anti-static belts are also available.

Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Bar skirt: optional heights of 20mm, 30mm, 40mm, 50mm, 60mm, etc.

Bar spacing: 100mm-1000mm range, other sizes can also be customized.

The conveying speed is generally: 0.1 ~ 10M/min; the speed can also be adjusted or fixed according to the needs of the user.

Solutions by Industry

The z type belt conveyor is especially suitable for the vertical transportation of food in snack manufacturing, frozen food production and bakery distribution. Conveyor systems provide efficient, gentle and safe food transportation, improving productivity, product quality and customer satisfaction in respective food handling and distribution operations.

| Customer Case | Snack Production Company | Frozen Food Processing Plant | Bakery Distributor |

| Application | Food Packaging and Distribution | Frozen food processing and packaging | Bakery product sorting and loading |

| Solution | An Australian snack manufacturing company produces a variety of packaged snacks, including crisps, pretzels and popcorn. They needed a conveyor system to transport the snack bags vertically from the packing area to the different floors of the distribution center. A Z-belt conveyor system is employed to efficiently and gently transport packaged snacks between floors. The non-slip strap holds the snack bag securely and prevents product damage during vertical transportation. | A food processing plant in the United States specializes in the production and packaging of frozen foods, including frozen vegetables, fruits and prepared foods. They needed a conveyor system to transport the frozen food trays from the processing area to the packing station on different floors, a Z type belt conveyor system was used to facilitate the vertical transfer of the frozen food trays without compromising product quality. | A bakery distributor in Italy, supplying a variety of retailers with fresh baked goods. They needed a conveyor system to sort the bread pallets of different products and load them onto delivery trucks from different floors of the warehouse. They employed a Z-belt conveyor system for efficient vertical sorting and loading of bread trays. Wedge-shaped conveyor belts securely hold pallets during vertical transport, ensuring accurate sorting and minimizing product damage. |