Air Cooling Vibrating Spiral Conveyor

The fan is used to dry and cool the material through the holes on the center column. It is suitable for cooling and drying high-temperature materials in modified plastic production lines.

Cooling method: fan blowing

Conveyor trough diameter: 300-900mm

Height: ≤6 meters

Conveying capacity: 3-5 tons/hour

Power: 2* (0.4-3)kw

Application: It can be used to cool, dry and lift materials. These machines are widely used in the processing of plastics, chemicals, mining and other processing industries.

Introduction of Air Cooling Vibrating Spiral Conveyor

Air cooling vibrating spiral conveyor is a specialized piece of equipment designed to cool materials while simultaneously conveying them. It combines the functions of a vibrating conveyor and an air cooling system, making it an efficient solution for various industrial applications.

Air cooling vibrating spiral conveyor uses fans to dry and cool materials through the holes on the center column. It is suitable for cooling and drying high-temperature materials in modified plastic production lines. It can provide vibrating conveyors with a conveying capacity of 500-4000kg/h.

What is Air Cooling Vibrating Spiral Conveyor used for?

Air cooling vibrating spiral conveyor is typically used for transporting materials in a continuous flow while simultaneously providing a cooling effect. The main functions and applications of this equipment include:

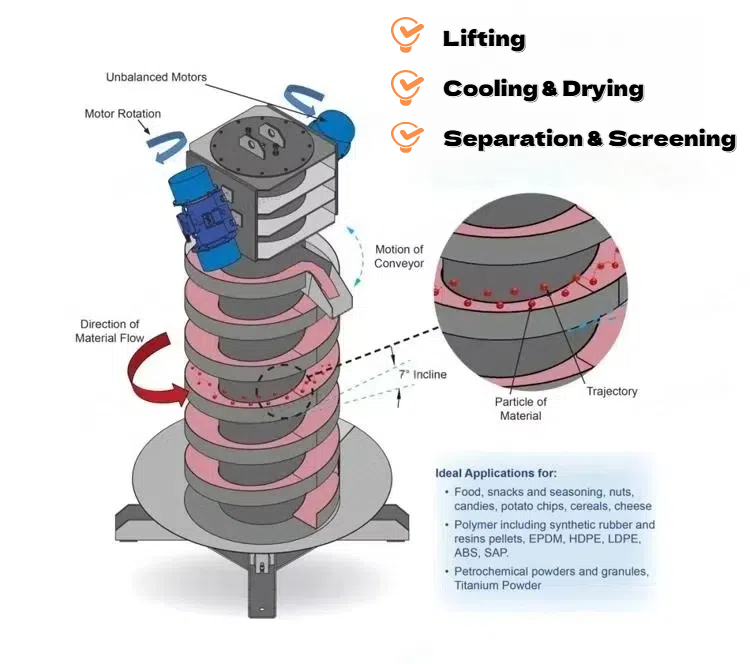

Material Lifting: The vibrating spiral conveyor efficiently transports materials from one point to another in a controlled and continuous manner.

Cooling: The integrated air cooling system helps in reducing the temperature of the materials being conveyed. This cooling feature is particularly useful for heat-sensitive materials or processes where maintaining a lower temperature is critical.

Separation and Screening: The vibrating action of the conveyor can also aid in the separation and screening of materials based on size, shape, or other characteristics.

Working Principle of Air Cooling Vibrating Spiral Conveyor

1. Material loading: Material is loaded onto the conveyor at the top or at a designated entry point. This can be done manually or automatically, depending on the system design.

2. Vibration generation: The conveyor is equipped with a vibration motor or exciter that generates controlled vibrations, which cause movement that moves the material up the conveyor trough.

3. Air cooling systems integrate ducts or fans to blow cool air over the material as it moves along the conveyor belt. This cooling effect is critical for temperature-sensitive products.

5. Discharge: The cooled material leaves the conveyor at the top or at a designated discharge point. This can be used for further processing, packaging or storage.

Advantages of Air Cooling Vibrating Spiral Conveyor

High conveying efficiency: The vertical lifting height can reach 6 meters, and the conveying capacity can reach 4 tons/hour.

Good cooling effect: The external fan can provide cooling during the material lifting process. By cooling, thermal damage is prevented, ensuring that the material maintains an ideal temperature during the lifting process, which is particularly suitable for temperature-sensitive products.

Gentle handling: The vibrating motion is gentle, minimizing material damage and degradation.

Space saving: The vertical lifting design makes the equipment occupy a small space, which is suitable for efficient use of plant space.

Closed design: The closed hoist can effectively prevent dust and harmful gases from polluting the working environment.

Reduction-oriented: Fewer moving parts compared to traditional conveyor systems, leading to lower maintenance needs.

Videos

Technical Parameters of Air Cooling Vibrating Spiral Conveyor

| Model | Lifting Capability(t/h) | Diameter of spiral chute(mm) | Lifting height(m) | Speed(rpm) | Double amplitude(mm) | Power(kw) |

| DZC300 | Up To 1.0 | 300 | ≤2.0 | 960 | 6-7 | 2*0.4 |

| DZC500 | Up To 2.0 | 500 | ≤3.0 | 960 | 6-8 | 2*0.75 |

| DZC550 | Up To 3.0 | 550 | ≤3.5 | 960 | 6-8 | 2*1.5 |

| DZC600 | Up To 3.0 | 600 | ≤4.0 | 960 | 6-7 | 2*1.5 |

| DZC800 | Up To 4.0 | 800 | ≤4.5 | 960 | 6-8 | 2*2.2 |

| DZC850 | Up To 4.0 | 850 | ≤5.0 | 960 | 6-9 | 2*2.2 |

| DZC900 | Up To 3.5 | 900 | ≤6.0 | 960 | 6-9 | 2*3.0 |

| DZC950 | Up To 4 | 950 | ≤8.0 | 960 | 6-9 | 2*3.7 |

Structure of Air Cooling Vibrating Spiral Conveyor

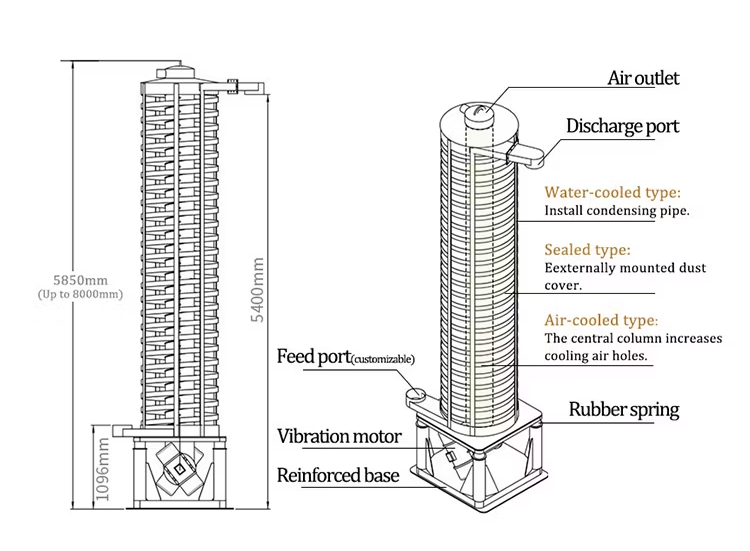

Frame: The basic framework of the equipment, usually made of steel, providing stable support and structural strength.

Vibration motor: The core component responsible for generating vibration, usually installed in a specific position of the frame. The motor generates vibration through an eccentric block or exciter.

Hoisting trough: The part along its surface along which the material is lifted, usually with an inclined or vertical design, and the surface may have an anti-slip treatment to prevent the material from sliding.

Fan system: Includes fans and air ducts to provide cooling air. The fan is usually installed on the top or side of the hoisting trough to ensure that the cooling air is evenly distributed.

Feed port: The part where the material enters the hoist, which can be manually or automatically fed, and is usually designed to facilitate the rapid loading of materials.

Discharge port: The part where the material is discharged after being lifted, designed to ensure smooth material flow, and may be equipped with an adjustment device to control the discharge speed.

Application of Air Cooling Vibrating Spiral Conveyor

Air cooling vibrating spiral conveyor combined with fan cooling function can play a role in the following applications:

Food processing industry: It can be used to quickly cool down heat-treated food to ensure product quality and safety.

Chemical industry: It is used to vertically transport chemical raw materials or products, and control the product temperature through fan cooling to avoid overheating or maintain a specific temperature range.

Metallurgical industry: It can be used to vertically transport molten metal or other heat-treated materials combined with fan cooling function, and reduce its temperature during transportation.

Plastic processing industry: It can be used to vertically transport molten plastic particles or products, and control the temperature of molten plastic through fan cooling to ensure production quality.

Glass manufacturing industry: It can be used to vertically transport molten glass and reduce its temperature during transportation to meet production needs.

Solutions by Industry

Additional Considerations

Material Properties: The type of material being cooled will influence the design and operation of the air cooling system.

Cooling Requirements: The desired cooling temperature and rate will determine the capacity and configuration of the cooling system.

Maintenance: Regular maintenance is essential to ensure optimal performance and longevity of the equipment.

By combining efficient conveying and cooling capabilities, air cooling vibrating spiral conveyors offer a valuable solution for industries that require precise temperature control during material handling.