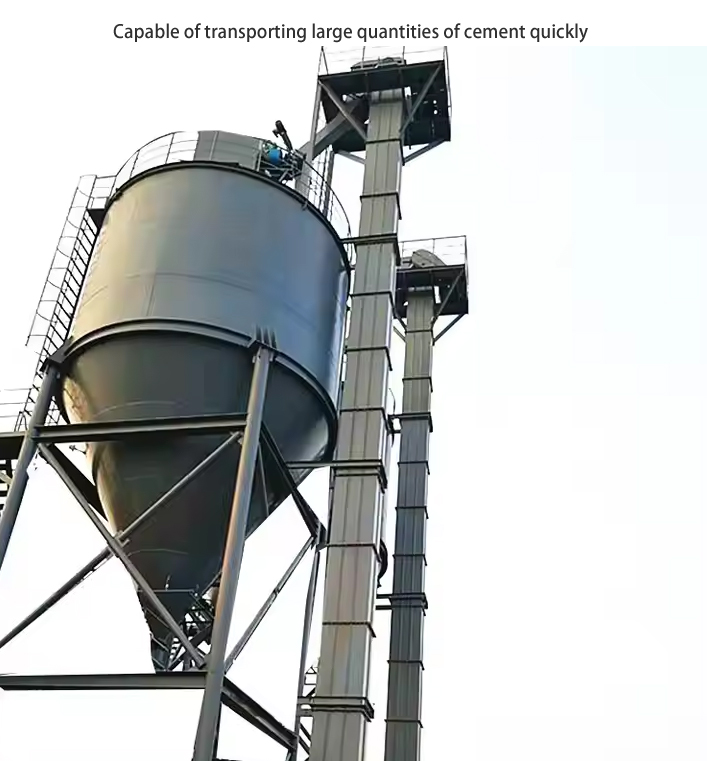

Cement Bucket Elevator

Typically used in cement plants for a variety of purposes, including feeding raw materials into the production process, transporting finished cement to storage silos, and other material handling tasks.

Lift height: 40 meters

Conveying capacity: 16-400m³/height

Motor power: 1.5-90KW

Application: Applicable to cement plants, cement production lines, construction sites, mines and other occasions that require vertical transportation of cement.

What is cement bucket elevator?

SCement bucket elevator is an essential piece of equipment in cement plants, used to move materials between different processing stages, such as from raw material storage silos to grinding mills, or from clinker coolers to cement silos.

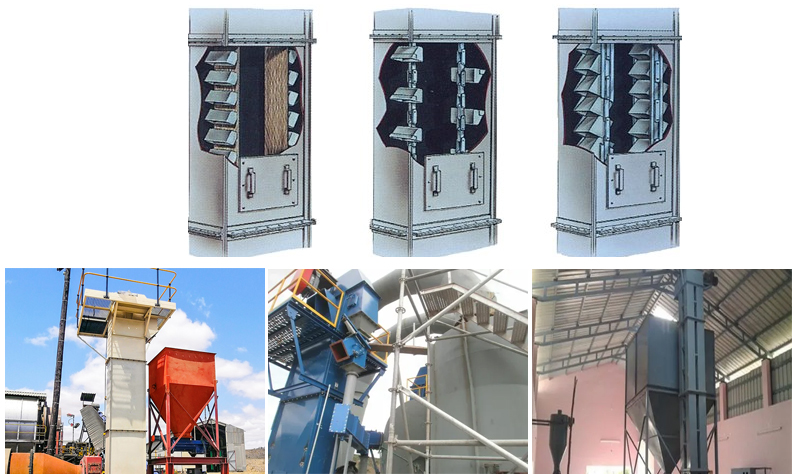

Cement bucket elevator consists of a continuous loop of chain or belt with attached buckets that scoop up the material at the bottom, lift it vertically, and then discharge it at the top.

Application scenarios of cement bucket elevator

Cement bucket elevator is a kind of equipment used for vertical transportation of bulk materials such as cement. It is widely used in cement plants, construction sites, mines and other occasions where materials need to be transported vertically. The following are some of the main applications of cement bucket elevator:

1. Cement production line: used to transport raw materials (such as limestone, clay, iron ore, etc.) from the ground to crushers, coal mills and other equipment, and to transport finished cement from mills to storage bins or packaging devices.

2. Construction site: used to transport materials such as concrete and mortar from the ground to high floors or other required locations to facilitate construction workers to carry out construction work.

3. Mixing station: used to transport different types of concrete mixing materials (such as cement, sand, aggregates, admixtures, etc.) from different storage locations to mixers or batching machines for mixing.

4. Concrete batching plant: vertically transport raw materials such as cement, sand, aggregates from the ground or storage area to concrete mixers or batching machines for concrete batching.

Videos

Working principle of cement bucket elevator

The working principle of a cement bucket elevator involves the following key steps:

Material Loading: The buckets of the elevator are filled with the material to be conveyed (such as cement, clinker, or other granular materials) at the bottom of the elevator.

Elevation: As the elevator starts operating, the loaded buckets are raised vertically through the action of a belt or chain that runs over a series of pulleys or sprockets.

Discharge: At the top of the elevator, the buckets tip over and discharge the material into a discharge chute, conveyor, or another receiving device.

Advantages of cement bucket elevator

Dust-proof design: Cement is prone to generate dust during the lifting process. Bucket elevators use sealed design and dust suppression devices to reduce dust dispersion and protect the environment and operator health.

Long service life: The wear of cement particles will accelerate the wear of elevator components such as buckets, chains or belts. Cement bucket elevators are usually made of strong materials such as steel to withstand the heavy load and abrasiveness of cement and other conveyed materials.

Load monitoring and protection: Load sensors and overload protection devices are installed to detect and avoid equipment overload operation in time to protect equipment safety.

Gentle handling: The bucket design reduces the collision and damage of materials, which can reduce the risk of breakage or degradation during transportation.

Technical parameters of cement bucket elevator

| Model |

Capacity m3/h |

Max. size of material (mm) |

||||

| Percentage % | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | 15 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 32 | 60 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 170 | 130 | 105 | 80 | 65 | 55 |

| NE200 | 210 | 170 | 135 | 100 | 85 | 70 |

| NE300 | 320 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 380 | 205 | 165 | 125 | 105 | 90 |

How to choose a cement bucket elevator?

Effects of different types of cement on bucket elevators

Particle size: Cement with larger particle size, such as cement clinker, has greater wear on the bucket and chain plate, so it is necessary to select materials with strong wear resistance.

Density: Cement with higher density requires higher drive power for the elevator, so it is necessary to select a model with higher motor power.

Water content: Cement with higher water content is easy to adhere to the bucket and chain plate, affecting the conveying efficiency, so it is necessary to select a bucket with self-cleaning function.

Corrosiveness: Some cements contain corrosive substances, which have a corrosive effect on the materials of the elevator, so it is necessary to select corrosion-resistant materials.

Different types of cement bucket elevators

According to the characteristics and process requirements of cement, the following types of bucket elevators can be selected:

TD belt bucket elevator: suitable for vertical transportation of cement powder, especially for occasions requiring smooth transportation and low noise.

Chain bucket elevator: suitable for conveying cement raw materials or clinker with larger particles, etc., and requiring simple equipment structure and strong wear resistance.

NE plate chain bucket elevator: suitable for conveying cement raw materials or finished products with larger particles and blocks, and requiring strong and durable equipment structure.

Solutions by Industry

-

A large cement plant

Use a cement bucket elevator to lift cement from storage tanks to the packaging area. The design of the elevator takes into account efficient transportation and space utilization, and can maintain a stable material flow during peak production, reducing material losses and maintaining high cement quality.

-

Building construction projects

Bucket elevators are used at construction sites to lift cement from the ground to high-rise concrete pouring areas. The equipment is designed to be mobile to adapt to the construction needs of different floors. Due to its closed design, dust is reduced and the construction environment is improved.

-

Concrete Mixing Plant

Bulk cement is lifted from the transport truck to the mixer using a bucket elevator. Equipped with an automatic control system, it achieves unattended operation. The low maintenance requirements of the equipment reduce operating costs and increase overall profitability.