Clinker Bucket Elevator

It is a device used to transport granular materials such as clinker (such as cement clinker) and is commonly used in cement production lines.

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-40 tons/hour

Lifting height: ≤20 meters

Lifting speed: 1.4-2 m/s

Introduction of Clinker Bucket Elevator

Clinker bucket elevator is a type of vertical conveyor used in cement plants or other industrial facilities for transporting clinker, which is a coarse, granular material produced during the cement manufacturing process. The clinker bucket elevator is specifically designed to handle the challenging characteristics of clinker, such as high temperatures, abrasiveness, and irregular particle sizes.

Clinker bucket elevators are essential for the smooth operation of cement production processes. They help in conveying the clinker from one process stage to another, such as from the kiln to the grinding mills or storage silos. The design and construction of clinker bucket elevators need to consider factors such as the required lifting capacity, the height and distance of vertical transportation, and the specific characteristics of the clinker being handled.

Types

Bucket elevators can generally be divided into the following types for different types of clinker:

1.Sintered clinker elevator: used to transport sintered clinker such as sintered ore, usually requiring the equipment structure to be sturdy and durable to cope with high temperature and wear.

2.Cement clinker elevator: specially used for conveying cement clinker, it is necessary to consider the characteristics of the material to prevent agglomeration and blockage.

3.Other special clinker elevators: according to actual needs, other types of bucket elevators can also be customized to meet the needs of conveying different types of clinker, such as silicate clinker, iron ore clinker, etc.

| Clinker type | Features | Applicable bucket elevator types |

| Ordinary clinker | The particle size distribution is wide, containing a certain amount of fine powder and coarse particles, and the abrasiveness is average. | TD type, TH type, TB type |

| High-aluminum clinker | The aluminum content is high, the melting point is high, and the temperature resistance of the equipment is high. | TH type, TB type, NE type |

| Low-alkali clinker | The alkali content is low, and the corrosion resistance of the equipment is high. | TH type, TB type, NE type |

| Special ingredient clinker | The composition is complex, and it may contain impurities such as iron and sulfur, and the wear resistance and corrosion resistance of the equipment are high. | TB type, NE type |

Uses

Below we will provide a detailed introduction to specific application scenarios in the clinker industry:

1. Transport between clinker cooler and mill: clinker can be lifted from the bottom of the cooler to the mill silo for grinding.

2. Transport between clinker storage and mill: When the mill needs clinker, the bucket elevator transports the clinker in the storage to the mill.

3. Transport before clinker packaging: clinker is transported from the storage or mill to the packaging machine.

4. Transport of clinker admixtures: During the cement production process, bucket elevators can transport admixtures to the batching system.

5. Clinker recovery: these lost clinkers can be recovered and sent back to the production line.

In addition to the common applications mentioned above, bucket elevators can also be used in the following occasions, such as conveying clinker to the kiln tail, conveying clinker to the screening system, etc.

video

Vertical Bucket Elevator for sand loading

Vertical Bucket Elevator with multiple outlets vertically lifts nuts to multiple silos

Technical parameters

| Model | Large feed sizemm | Hopper | lift heightm | Lifting capacity (m3/h) | Hoist weight | ||

| Bucket distancemm | WidthMM | CapacityL | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | Check and determine according to the specific vertical bucket elevator ordering general drawing |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

| Note: The maximum conveying capacity in the table is calculated according to the filling factor ψ-0.8, which is for reference only. | |||||||

Choosing a suitable clinker bucket elevator requires comprehensive consideration of the following factors:

1. Characteristics of clinker: particle size, density, abrasiveness, etc.

2. Conveying capacity: The amount of clinker that needs to be conveyed per hour.

3. Lifting height: The height to which the clinker needs to be lifted.

4. Working environment: temperature, humidity, etc.

Advantages

Sealing: Clinker may generate dust during the lifting process. The equipment usually adopts a closed structure to effectively prevent material leakage and reduce environmental pollution.

Anti-caking: The clinker bucket elevator adopts a suitable bucket shape and bucket barrel structure to prevent clinker caking and ensure continuous transportation.

Wear and corrosion resistance: Use materials with good wear and corrosion resistance to manufacture equipment components to extend the service life of the equipment.

Heat insulation design: For high temperature environments, design heat insulation measures or use high temperature resistant materials to ensure the normal operation of the equipment.

Flexible configuration: It can be customized and adjusted according to the needs of the production line to adapt to different process requirements.

Composition Structure

The clinker bucket elevator is mainly composed of a hopper, a frame, a transmission chain, a lifting rod and a driving device. The hopper is used to accommodate materials, the frame is used as the supporting structure of the entire hoist, the transmission chain transmits power to the lifting rod through the transmission wheel and the chain, the lifting rod is responsible for loading and transporting materials, and the driving device provides power for the hoist.

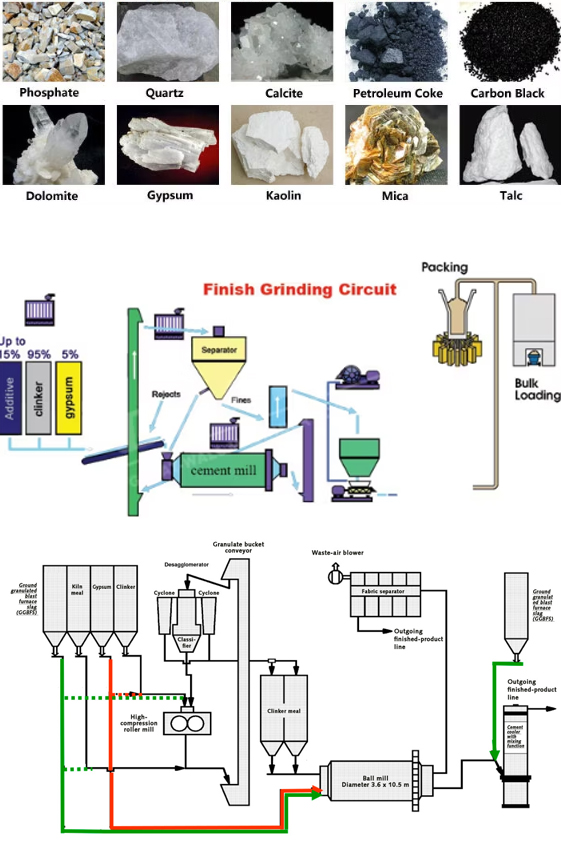

Systematic solution

In cement plants, bucket elevators are mainly used to transport raw materials such as limestone, clay and sand to the kiln, where they are heated to form clinker. The clinker is then ground into cement powder. Bucket elevators also play a vital role in the recycling process, transporting clinker to storage silos and then to the grinding mill.

Working Principle

The working principle of the clinker bucket elevator can be briefly described as follows: After the driving device is started, the power is transmitted to the lifting rod through the transmission chain, and the lifting rod starts to move, and the material is lifted from the hopper to a high place. During the lifting process, due to the effect of gravity, the material will fall naturally, and at the same time, the movement of the transmission chain will also drive the lifting rod to drop. When the material reaches the target position, the driving device stops working, the lifting rod stops moving, and the material is dumped to the target position.