Corn Bucket Elevator

Used to lift corn and other granular materials vertically from low to high, suitable for material transportation during corn storage, processing and transportation.

Material particle size: 25-70mm

Lifting capacity: 5.4-30 tons/hour

Lifting height: ≤40 meters

Application: Widely used in corn processing plants, corn storage facilities and corn production lines.

Introduction of Corn Bucket Elevator

Corn bucket elevator is a specialized type of conveyor system designed to transport corn (maize) vertically. It uses a series of buckets attached to a belt or chain to lift the corn from one level to another, typically from storage bins to processing areas or packaging lines.

Bucket elevators are suitable for lifting corn particles with a particle size range of 1 to 10 mm. They can transport everything from fine corn flour to larger corn kernels. The bucket design and conveying method of bucket elevators can effectively maintain the integrity of corn kernels, avoid particle breakage or damage, and ensure product quality.

Applications

1. Grain Processing Plant: The corn bucket elevator is widely used in grain processing plants, which is used to transport corn from the ground to process equipment in different places to improve processing efficiency.

2. Grain warehousing: The corn bucket elevator can be used to transport corn from the ground to the top of the granary to achieve automated management of grain storage.

3. Corn processing production line: The corn bucket elevator can be used as an important part of the corn processing production line, and the corn is transported from a process equipment to the next process equipment to improve production efficiency.

4. Grain logistics and warehousing: The corn bucket elevator can be used in the corn storage and transportation process in the grain storage storage system to achieve rapid and efficient material improvement.

In short, the corn bucket elevator has the advantages of efficient, fast, space savings, good sealing, simple operation, reliable and stable and other advantages. There are extensive application prospects in the scenarios such as grain processing plants, grain storage, corn processing lines, and grain storage storage storage.

Videos

Working Principle

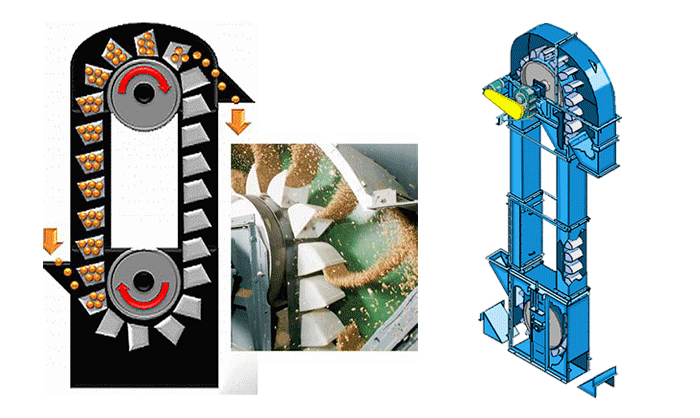

First, install corn and other materials into the feed inlet at the bottom. When the driver is activated, the motor provides power, and the power is passed to the transmission wheel through the reducer and a shaft. The rotation of the transmission wheel will drive the dragging chain, and the lift barrel on the dragging chain performs a lifting movement through the guidance of the guide rail.

When the increase in the barrel drops to the bottom, the feed inlet is opened, and the material is installed in the lift in the barrel. As the raising barrel rises, the material is raised to the top. When the barrel is raised to the position of the storage or storage equipment, the pour of the barrel is poured and the material is dumped into it. Then raise the barrel to continue to move down, and return to the bottom through the guide rail to prepare the next material loading.

Advantages

Applicable to a variety of granular materials: In addition to corn, bucket elevators are also suitable for conveying various granular materials. They are versatile and can meet the conveying needs of different materials.

Vertical conveying needs: Bucket elevators are suitable for vertical material conveying and are very effective for corn conveying tasks that need to be lifted from the bottom to the top.

Maintaining particle integrity: The bucket design and conveying method of the bucket elevator can effectively maintain the integrity of corn particles, avoid particle breakage or damage, and ensure product quality.

Efficient and stable conveying: Bucket elevators can continuously and stably convey corn particles, improve production efficiency, and ensure the smooth progress of the production process.

Space saving: Bucket elevators take up little space in the vertical direction, which can save production space and are particularly suitable for production environments with limited space.

Technical Parameters of Corn Bucket Elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

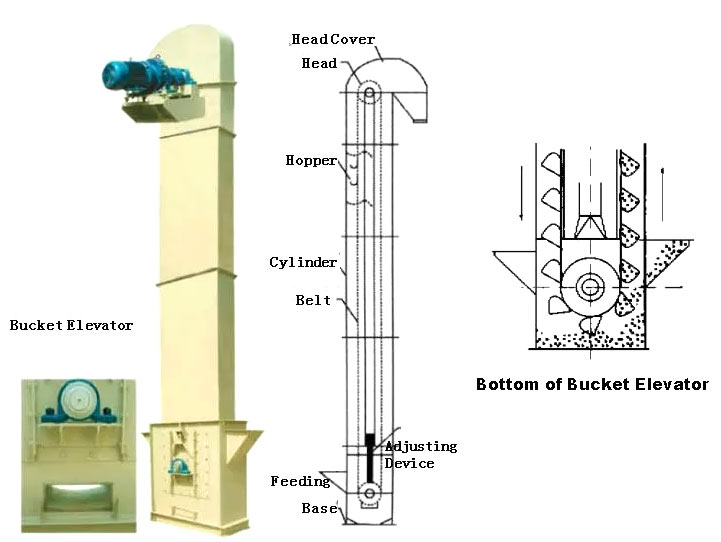

Composition Structure

1. Rangers: The rack of the racket is formed by the steel plate welded, which has sufficient strength and stability to support and fix other components.

2. Driver device: It is mainly composed of electric motors, reducers, coupling and transmission wheels. The motor provides power, and the transmission wheels use the rotation of the dragging chain to achieve the lifting and lifting movement of the barrel.

3. Enhanced barrel: It is a loading device for corn, which is made of metal or plastic. The shape is bucket. The raising barrel moves through the guidance of the guide track, exercise along the lifting movement trajectory of the lifter, and transports the material from the lower part to the upper part.

4. Drag chain: consisting of multiple high -intensity chains, continuously surrounds the transmission wheel and guide rail. The role of the dragging chain is to connect the lift barrel together and drive the movement of the barrel through the rotation of the transmission wheel.

5. Search: Located on both sides of the elevator, used to guide the motion of drag chains and enhance barrels. The design and installation of the guide rail is stable, and it is matched with the size of the increasing barrel and the dragging chain to ensure that it runs normally.

What are the different types of buckets used in corn bucket elevators?

In corn bucket elevators, various types of buckets can be used based on the specific requirements of the application. Some common types of buckets used in corn bucket elevators include:

Standard Buckets: These are the most common type of buckets used in bucket elevators. They have a traditional shape and are suitable for general-purpose lifting of corn and other grains.

Deep Bottom Buckets: These buckets have a deeper bottom compared to standard buckets, allowing them to hold more material. They are often used when higher capacities or larger volumes of corn need to be lifted.

Non-Spill Buckets: Non-spill buckets are designed to prevent material from spilling back into the elevator. They are often used for materials that tend to stick or create dust during handling, ensuring a cleaner operation.

Venting Buckets: Venting buckets have additional vent holes or slots to allow air to escape during the lifting process. They are useful for reducing material degradation or dust accumulation during vertical transportation.

How to choose a Corn Bucket Elevator?

Corn bucket elevators are usually suitable for conveying corn with medium to fine particle sizes, including corn kernels, crushed corn, etc. For corn with different particle size ranges, you can select according to the following suggestions:

Medium-sized corn kernels: usually have moderate bucket capacity and appropriate conveying speed, suitable for general corn kernel conveying tasks.

Fine-sized corn kernels or crushed corn: consider using a deep bottom bucket or low-profile bucket elevator. These types of elevators are designed with a deeper bucket bottom or a lower bucket height, which helps to accommodate more fine particles or fragments and improve conveying efficiency.

Wet or sticky corn kernels: consider choosing an elevator with a bucket. The bucket is designed with a wider top opening, which helps to handle wet and sticky particles and reduce clogging or adhesion problems.

When choosing a suitable corn bucket elevator, you need to consider the particle size, moisture content, and conveying capacity requirements of the corn to ensure that the selection matches the actual application needs, so as to achieve efficient and stable corn conveying operations.