Flour Bucket Elevator

Designed to efficiently and safely transport large quantities of flour from one level to another within a processing plant or facility.

Material: SUS304/316L stainless steel

Height: ≤40 meters

Transport capacity: 5.4-40 tons/hour

Application: Flour mills, video mills, bakeries, baking plants, biscuit production plants, etc. to transport flour from the ground to different floors or process equipment.

Introduction of Flour Bucket Elevator

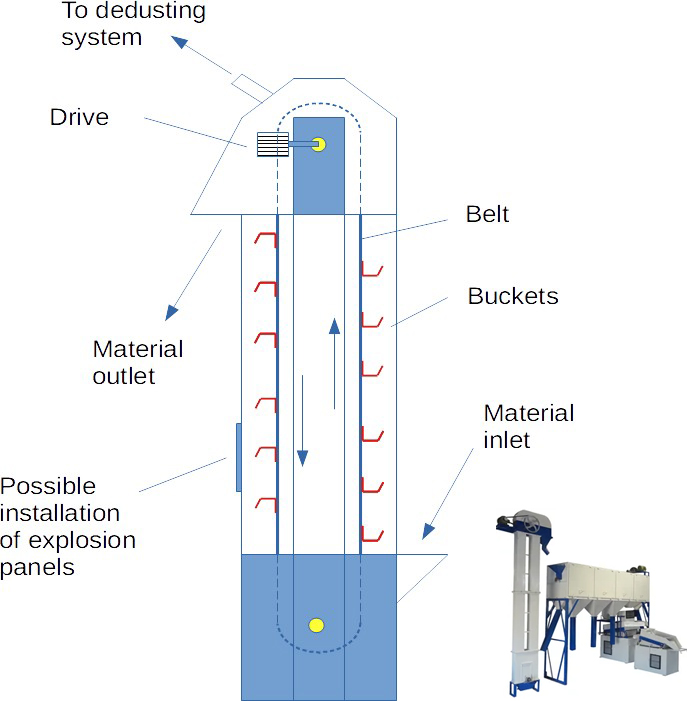

Flour bucket elevator is a common material conveying equipment, which is mainly used to lift powdery or granular materials such as flour from a low place to a high place, so as to achieve the purpose of transportation and storage. It consists of a hoist body, a power unit, a vehicle or material transportation device, and a safety device.

Flour bucket elevators can be used in flour production to transport grain from storage silos to the milling process, to move flour between different stages of the grinding process, such as from the mill to the sieve, or to lift flour to the packaging machine.

Use

Flour bucket elevators can convey flour of various mesh sizes, depending on the design and configuration of the equipment. Generally speaking, bucket elevators are suitable for the following flours:

Low-gluten flour (such as cake flour): usually between 70-90 mesh, suitable for light materials.

Medium-gluten flour (such as bread flour): generally between 90-110 mesh, suitable for daily baking.

High-gluten flour (such as noodle flour): usually between 110-130 mesh, suitable for making noodles and high-gluten pasta.

Application scenarios

Flour bucket elevator is a common conveying equipment, mainly used for vertical conveying of powdered materials such as flour. The following are some specific applications of flour bucket elevator:

Flour mill: used to convey flour from the ground to different floors or process equipment.

Food processing factory: used for conveying and lifting powdered raw materials such as flour and starch.

Bakery: convey flour from the warehouse or mixing area to the mixer or other processing equipment.

Baking factory: used for conveying raw materials such as flour and sugar, and conveying the mixed dough to the furnace equipment.

Biscuit production plant: used for conveying raw materials such as flour to ensure smooth supply of raw materials on the production line.

Grain processing plant: used for vertical conveying of raw materials such as wheat flour.

Videos

Working principle

The working principle of the flour bucket elevator is to lift the material from a low place to a high place through the elevator body. When the motor is started, the power is transmitted to the sprocket or screw fitting on the upper part of the hoist body through the reducer to make it move. The material is caught by the chain plate or screw fittings on the upper part of the elevator body. With the rotation of the sprocket or screw, the material is lifted to a high place along the movement direction of the elevator body, and finally transported to the destination by a trolley or material transportation device.

Advantages

1. Hygiene: Flour bucket elevators are usually made of stainless steel and other food-grade materials, which can ensure that flour is not contaminated during transportation and meet food processing hygiene standards.

2. Maintain flour quality: The elevator is reasonably designed to prevent flour from being squeezed or contaminated during transportation, which helps to maintain the quality and taste of flour.

3. Avoid blockage: The bucket design makes it difficult for flour to be blocked during transportation, ensuring the continuity and stability of the production line.

4. Efficient transportation: The elevator can quickly and efficiently transport a large amount of flour vertically, saving manpower and time costs.

5. Save space: Compared with traditional inclined conveying equipment, the vertical conveying method of the elevator can save space and make the production line layout more flexible.

Technical parameters

| Model | Large feed sizemm | Hopper | lift heightm | Lifting capacity (m3/h) | Hoist weight | ||

| Bucket distancemm | WidthMM | CapacityL | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | Check and determine according to the specific vertical bucket elevator ordering general drawing |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

| Note: The maximum conveying capacity in the table is calculated according to the filling factor ψ-0.8, which is for reference only. | |||||||

Composition structure:

Flour bucket elevator is mainly composed of the following parts:

(1) Elevator body: including the upper and lower parts, with scraper chains or screw fittings connected in the middle for lifting materials;

(2) Power device: usually driven by a motor, which transmits power to the hoist body through a reducer;

(3) Personnel vehicle or material transportation device: used to transport materials to the elevator port or discharge port;

(4) Safety devices: including upper and lower limit switches, power-off protection, etc.

To sum up, the flour bucket elevator has the advantages of simple structure, high lifting efficiency, and wide applicability. It is suitable for flour production lines, grain storage systems, chemical plants, and construction sites. During use, it is necessary to pay attention to the setting of safety devices and regular maintenance to ensure the safe and normal operation of the hoist.

Solutions by Industry

-

Flour bucket elevator for a large flour mill

Application: Use bucket elevator to transport ground flour from the grinder to the storage bin.

-

Flour bucket elevator for a large food processing plant

Application: transport different types of flour from the storage area to the mixing area。

-

Flour bucket elevator for a feed processing plant

Application: The bucket elevator is responsible for transporting flour from the warehouse to the mixing equipment.