Fly Ash Bucket Elevator

Lift fly ash from a lower position to a higher position, such as transporting fly ash to a storage silo, mixer or other production equipment for subsequent processing.

Feeding size: 100 mesh to 325 mesh

Lifting capacity: 5.4-40 tons/hour

Lifting height: ≤30 meters

Lifting speed: 1.4-2 m/s

Application: Mainly used for conveying fly ash or other powdery materials, and widely used in industrial sites such as waste incineration plants, thermal power plants, cement plants, etc.

Introduction of Fly Ash Bucket Elevator

Fly ash bucket elevators are mainly used in industries such as cement, building materials, chemicals and electricity, especially in cement production to transport fly ash from storage silos to the mixture.

The fly ash bucket elevator conveys the fly ash from the bottom to the top through the bucket elevator chain, bucket material trough and other devices, and dumps the fly ash into the designated collector or processing equipment by gravity.

Type

Fly ash bucket elevators can be divided into the following categories according to different types of fly ash and their conveying requirements:

1. Light bucket elevator: suitable for conveying lighter and finer fly ash, usually used for small-scale production or laboratory applications.

2. Heavy bucket elevator: for fly ash with larger or heavier particle size, a more robust structure is designed to withstand higher loads.

3. High temperature resistant bucket elevator: for high temperature fly ash, it is made of high temperature resistant materials and is suitable for high temperature environments such as the power industry.

Application

Fly ash bucket elevator is a common conveying equipment, mainly used in waste incineration plants, thermal power plants, cement plants and other places to convey fly ash or other powdered materials. The following are the main uses and application scenarios of fly ash bucket elevator:

Fly ash treatment:used to collect, convey and process fly ash, which is solid waste generated after coal combustion in thermal power plants and usually needs to be transported to storage or treatment facilities.

Waste incineration plant: used to transport ash produced after incineration, and transport it from the bottom of the combustion furnace to the ash collector or other treatment equipment.

Cement plant: used to transport fly ash to equipment such as mixing silos or coal mills for the preparation of cement raw materials.

Power plant: Fly ash is a by-product after combustion, and bucket elevators are used to transport it from the ash hopper to the storage silo or external transportation for subsequent use.

Industrial furnace charge: In some industrial furnace charge production processes, fly ash can be used as an additive, and bucket elevators are responsible for transporting it to the furnace charge mixing system to ensure uniform raw materials.

Videos

Working principle

The working principle of the fly ash bucket elevator is mainly to transport the material from the bottom to the top or vice versa by continuous lifting movement. Its working process is as follows:

1. In the initial state, the lifting bucket is located in the lower container, and the material enters the lifting bucket by its own weight.

2. When the motor is started, the transmission device drives the lifting barrel to move upwards, and the material is lifted to the upper container.

3. The material is unloaded in the upper container to complete the lift.

4. The lifting barrel stops moving under the action of the limit switch at the top of the upper container and starts to descend.

5. The lifting bucket stops after it descends to the position of the limit switch on the top of the lower container, and the material enters the lower container at this time.

6. Repeat the above steps in a cycle to achieve continuous lifting movement.

Features and Benefits

First of all, the structure of the fly ash bucket elevator is simple, consisting of the elevator body and the driving device. The machine body adopts bucket structure, so that the materials can pass through smoothly. The driving device is usually composed of a motor and a reducer, which is easy to operate and maintain.

Secondly, the operation of the fly ash bucket elevator is stable. The equipment runs smoothly, with low noise and vibration, and can provide stable material conveying effect.

Again, the conveying efficiency of the fly ash bucket elevator is high. Compared with other common material conveying equipment, fly ash bucket elevator has higher conveying efficiency.

Technical parameters

| Model | Large feed sizemm | Hopper | lift heightm | Lifting capacity (m3/h) | Hoist weight | ||

| Bucket distancemm | WidthMM | CapacityL | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | Check and determine according to the specific vertical bucket elevator ordering general drawing |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

| Note: The maximum conveying capacity in the table is calculated according to the filling factor ψ-0.8, which is for reference only. | |||||||

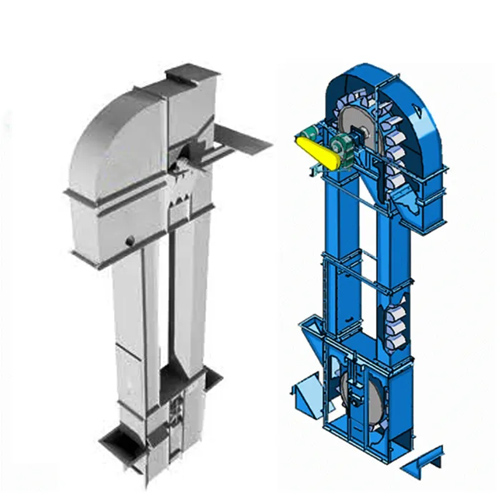

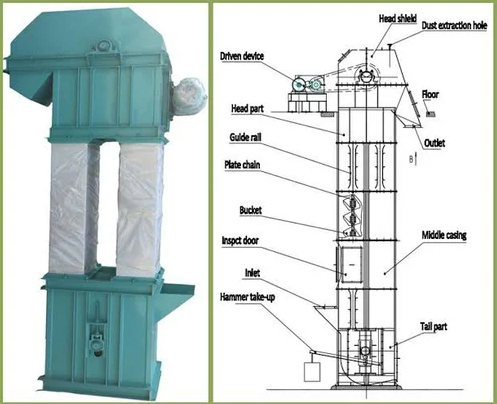

Structure

1. Lifting frame: The lifting frame is the load-bearing part of the fly ash bucket elevator. It is usually welded by steel plates and has sufficient strength and rigidity to ensure the overall stability of the hoist.

2. Driving device: The driving device is used to provide the power of the hoist, usually using a combination of motor, reducer and coupling to drive the chain or belt for movement.

3. Lifting bucket: The lifting bucket is the main conveying device of the fly ash bucket elevator. It is usually welded by steel plates, has a large capacity and strength, and can carry the weight of materials.

4. Transmission device: The transmission device is composed of gears and chains. By connecting the motor and the lifting bucket, the speed transmission of the motor and the movement of the lifting bucket are realized.

5. Electrical control system: The electrical control system is used to control the start, stop and operation of the hoist, usually including the main motor, circuit breaker, button switch and other equipment.

Solutions by Industry

-

For cement plant

Application: Used to transport fly ash from storage silos to the mix.

Height: 30 meters

-

For thermal power plants

Application: Pipe boiler bottom ash, fly ash, etc. to ash storage yard or ash storage.

Height: 40 meters

-

For chemical plant

Application: Transport fly ash to environmental protection facilities for treatment.

Height: 12 meters