Gravel Bucket Elevator

Designed to efficiently transport bulk materials vertically, especially granular materials such as gravel, sand and crushed stone.

Particle size: 20mm

Lifting capacity: 16-400m³/h

Lifting height: ≤40 meters

Application: Used in mining and mines, ore processing, construction sites and other industries to lift gravel, crushed stone and other construction materials from the ground to a high place.

Introduction of Gravel Bucket Elevator

Gravel bucket elevator is a type of equipment used in various industries to vertically lift and transport gravel or similar bulk materials. This type of elevator typically consists of a series of buckets attached to a chain or belt that moves in a continuous loop, allowing for the efficient vertical conveyance of materials.

Gravel bucket elevators are commonly used in industries such as mining, construction, agriculture and processing plants that require vertical transport of bulk materials such as gravel, sand, ore or aggregates. They can be customized to meet specific material handling requirements, including different capacities, bucket sizes and discharge heights.

What Gravel Sizes Are Suitable for Gravel Bucket Elevators?

Gravel bucket elevators are generally suitable for lifting gravel of the following particle sizes:

Coarse gravel: particle size range is 10-25 mm, suitable for larger gravel particles, commonly found in construction and infrastructure projects.

Medium gravel: particle size range is 5-10 mm, suitable for batching concrete and other construction materials.

Fine gravel: particle size range is less than 5 mm, suitable for lifting fine-grained materials such as fine sand and stone chips.

Applications of Gravel Bucket Elevator

Gravel bucket elevators are widely used in the industrial and construction fields, mainly for handling and conveying gravel and similar granular materials. The following are common applications of gravel bucket elevators:

1. Mining and mines: used to transport mining products such as gravel and ore from mines or mining sites vertically to the ground or other processing equipment.

2. Construction sites: used to lift construction materials such as gravel and crushed stone from the ground to high places, such as concrete mixing plants or building structure construction sites.

3. Sand and gravel plants and concrete mixing plants: used to transport raw materials such as gravel and crushed stone to crushers, screening equipment or concrete mixers for processing and production.

4. Cement plants and ore processing: used to transport gravel and ore to crushers, mills and other equipment for processing during cement production and ore processing.

5. Ports and docks: At ports and docks, used to unload gravel, ore or other bulk materials from ships for further processing or transportation.

Videos

Advantages of Gravel Bucket Elevator

1. Gravel particles are prone to accumulation and blockage during the lifting process. Bucket elevators use specially designed buckets that can effectively capture and transport granular materials and reduce the possibility of blockage and accumulation.

2. Wear-resistant materials and structures: The key components of the elevator are designed with wear-resistant materials and sturdy structures to resist the wear and damage caused by particles such as gravel to the equipment.

3. Closed design: Bucket elevators usually have a closed design, which can effectively control dust and particle flying and keep the working environment clean.

4. Efficient design: The continuous bucket system is used to minimize material spillage and maximize efficiency.

5. Customized design: According to specific needs and material characteristics, bucket elevators can be customized, including bucket size, lifting speed and other parameters to improve lifting efficiency and stability.

Technical parameters

| Model | Elevating capacity (m³/h) | Maximum size of material ( m ) | ||||

| Allowable percentage % | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | 16 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 31 | 90 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 165 | 130 | 105 | 80 | 65 | 70 |

| NE200 | 220 | 170 | 135 | 100 | 85 | 70 |

| NE300 | 320 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 441 | 205 | 165 | 125 | 105 | 90 |

Gravel handling and conveying systems

Gravel bucket elevators are often used in conjunction with other equipment to build a complete material handling and conveying system. Here are some common uses for bucket elevators with different equipment:

Crushing equipment (such as jaw crushers): Bucket elevators can be used to vertically convey crushed granular materials such as gravel to downstream screening equipment or storage equipment.

Screening equipment (such as vibrating screens): Bucket elevators can vertically convey screened gravel particles to the next processing stage, such as concrete mixing plants or packaging equipment.

Conveyor belts: Bucket elevators transfer granular materials such as gravel from horizontal conveyor belts to vertical directions for efficient vertical transportation.

Processing equipment (such as mills): Bucket elevators can convey processed gravel particles to the next processing stage, such as mills or mixers.

Storage equipment (such as silos): Elevators can vertically convey materials such as gravel to silos or storage equipment for subsequent storage or distribution.

Packaging equipment: The elevator is used to transport the processed gravel particles to the packaging equipment for packaging and transportation.

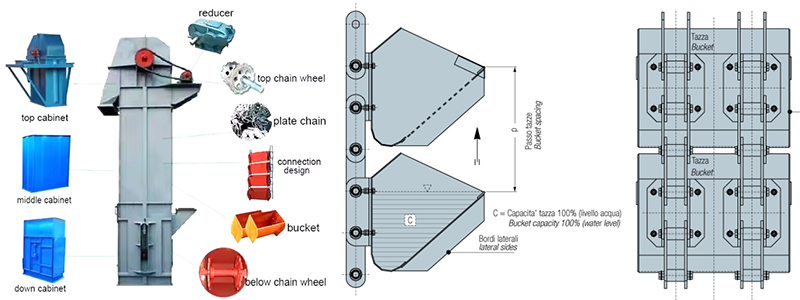

Structures of Gravel Bucket Elevator

Buckets: These are typically made of durable materials like steel or cast iron to withstand the abrasive nature of gravel and other heavy materials.

Belt or Chain: The driving mechanism that powers the elevator and carries the buckets.

Head and Foot Shafts: These support the pulleys and bearings that guide the belt or chain.

Housing: A protective enclosure that houses the moving parts of the elevator.

Drive Motor: Provides the power to operate the elevator.

Solutions by Industry

-

Building materials supplier

A large building materials supplier, focusing on the production and supply of concrete and gravel, uses a gravel bucket elevator to lift coarse gravel extracted from the quarry vertically to the processing area. The equipment improves production efficiency, reduces the need for manual handling, and increases lifting capacity by 30%.

-

Mining company

A mining company, focusing on the mining and processing of gravel, serving construction and infrastructure projects, uses a gravel bucket elevator to lift the mined gravel from the mine to the screening and washing area. The high efficiency of the equipment reduces the processing time of gravel by 40%.

-

Recycling and reuse center

A company focusing on the recycling of construction waste is committed to converting waste materials into reusable resources. It uses a gravel bucket elevator to lift the recycled mixed gravel materials to the sorting and processing area for further classification and processing. The company's recycling efficiency has increased by 25%.