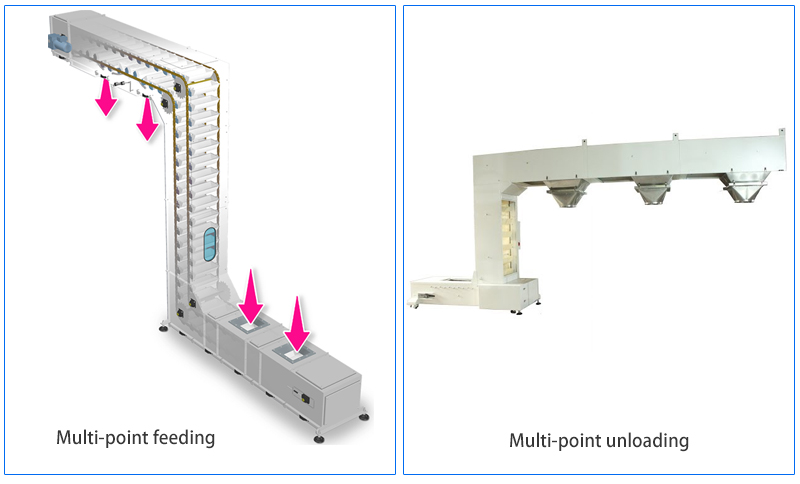

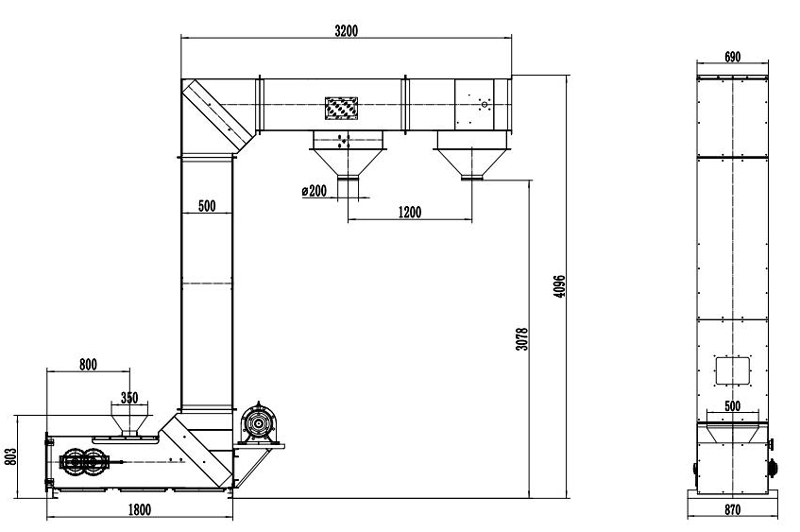

Multi-point feeding z-type elevator

Multi-point feeding z-type elevator is used to solve high-bay silos/packaging equipment and other situations that require multi-point feeding.

Barrel material: food grade PP, stainless steel, ordinary PVC

Conveying speed: 2-5 cubic meters per hour

Bucket volume: 1.8L, 4.0L and 6.0L (customizable)

Discharge height: 2-12 meters

Conveying capacity: 3-10m³/h

Number of discharge points: 2-7 can be designed according to demand

What is a multi-point feeding z-type elevator?

Multi-point feeding z-type elevator is used to lift bulk materials from a low place to a height of 2-12m, and feed tall silos, elevated packaging machines and other equipment, and the upper ends of Multi-point feeding z-type elevators are side by side The design of multiple discharge points means that it can complete the feeding work for multiple equipment that needs to be fed, saving a lot of space and equipment purchase costs.

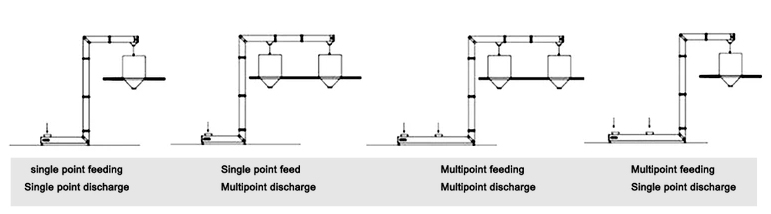

Types of multi-point feeding z-type elevator

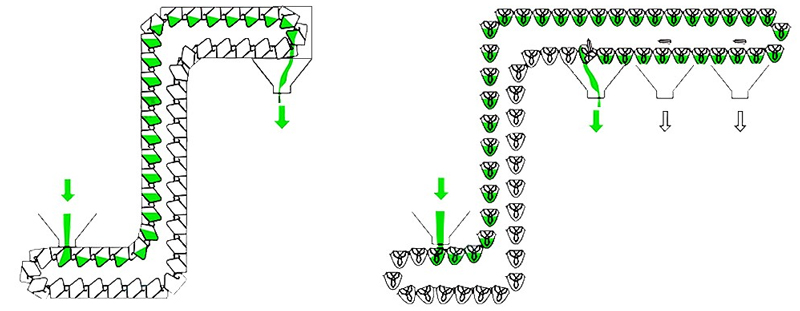

Multi-point feeding z-type elevator can generally be divided into multi-point feeding and multi-point unloading. This design helps to improve the efficiency and flexibility of material transportation.

1.Multi-point feeding: In the multi-point feeding design, the Z-type elevator can receive materials from different locations at the same time. This design is suitable for situations where materials need to be delivered to the elevator from multiple sources at the same time. With multi-point feeding, mixed delivery of materials of different types or sources can be achieved to meet complex production needs.

2.Multi-point unloading: The multi-point unloading design allows the Z-type elevator to unload materials at different locations at the same time. This design helps to efficiently transport materials to multiple destinations. With multi-point unloading, flexibility and efficiency in sorting, distributing or further processing of materials can be achieved.

Application of multi-point feeding z-type elevator

Multi-point feeding z-type elevator, as the main part of the packaging line, is suitable for conveying bulk, dry, free-flowing granular products and powders in a continuous and closed manner, with multi-point discharge, capable of satisfying multiple silos in a row continuous feeding.

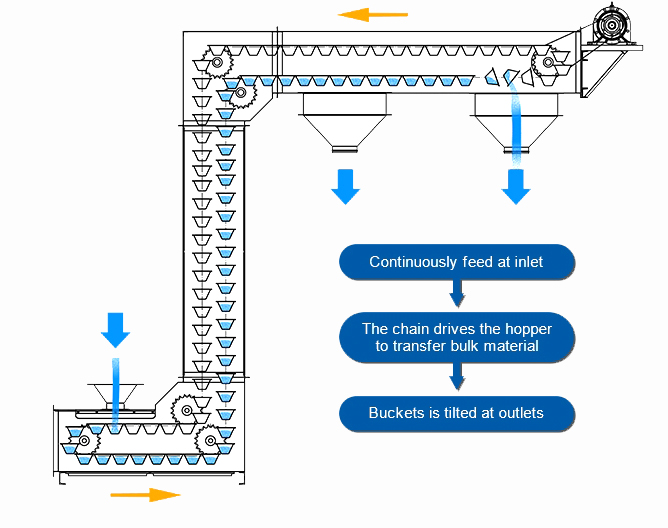

How does a multi-point feeding z-type elevator work?

The material enters the bucket of the elevator through a feeding device (such as a vibrating feeder). The chain or belt of the bucket elevator drives the bucket to rise along the vertical track of the elevator. The material is lifted to a set height in the bucket. At different unloading points of the elevator, the bucket will discharge the material through a specific unloading device (such as flipping, sliding, etc.).

Video

Features and Benefits

It can lift the product from a low position to a combination scale or other equipment. The number of discharge openings can be as many as 7 positions, and each position is about 2 meters apart. It is very suitable for replacing multiple conveyors in a workshop with limited space, and it is extremely gentle in operation. It will not cause material damage, and it can transport fragile and fragile biscuits, potato chips and other bulk foods.

1. 2-7 discharge ports are available, multiple inlets and multiple discharge points can be combined into one system, combining or separating product streams as required.

2. One machine can complete the work of horizontal conveying and vertical lifting, and the discharge height, feed height, length, etc. can be customized.

3. Gently handle fine materials to maintain product integrity, including abrasives and coarse aggregates and minerals.

4. It can be used in conjunction with electronic weighing scales, and the control circuit is used to control the position of materials to realize automatic feeding and shutdown functions.

Comparison between single-point feeding and multi-point feeding

| Difference | Single point feeding | Multi-point feeding |

| Feeding method | Single inlet | Multiple inlets |

| Structural complexity | Simple | Complex |

| Applicable scenarios | Single source of material, stable conveying volume | Material sources are scattered and need to be adjusted flexibly |

| Flexibility | Low | Higher |

| Cost | Low | Higher |

Technical parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Solutions by Industry

Grain processing: In grain processing plants, multi-point feeding z-type elevators can be used to transport different varieties of grain from storage areas to processing workshops.

Feed production: In feed production lines, multi-point feeding z-type elevators can transport a variety of raw materials (such as corn, soybean meal, minerals, etc.) from different silos to mixers to automate formula proportioning.

Cement production: In cement production lines, multi-point feeding z-type elevators can transport cement raw materials, clinker and other materials from mills to packaging machines.

Food processing: multi-point feeding z-type elevators can be used to transport various food raw materials, such as sugar, salt, seasonings, etc.