Stainless steel Z type bucket elevator

Stainless steel Z type bucket elevator uses 304 or 316L material, mainly used to lift bulk food materials into the packaging machine.

Machine shell material: 304 or 316L food grade stainless steel

Hopper material: food grade ABS

Hopper volume: 1.8L, 4.0L and 6.0L (can be customized)

Lifting height: 2-12m

Conveying speed: 2-5m³/h

Conveying capacity: 3-10m³/h

Inlet and outlet: single or multiple

Product introduction of Stainless steel Z type bucket elevator

Stainless steel Z type bucket elevator refers to a Z-type bucket elevator that is constructed using stainless steel materials. Stainless steel is a popular choice for bucket elevators in industries where hygiene, corrosion resistance, and durability are crucial factors.

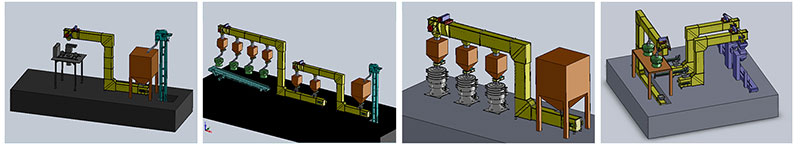

Stainless steel Z type bucket elevator is designed to transport bulk materials vertically by a combination of horizontal and vertical movement. The Z-type elevator is named for its unique Z-shaped structure. Unlike traditional bucket elevators, which move material in straight vertical lines, Z-Elevators utilize a series of alternating horizontal and vertical sections for a more compact and efficient design.

Application of Stainless steel Z type bucket elevator

Stainless steel Z type bucket elevators are widely used in many industries. Here are some common uses for stainless steel Z type bucket elevators:

Food processing industry: used for vertical conveying of various food raw materials and finished products, such as grains, nuts, candies, vegetables, meat, etc. Its stainless steel material and hygienic design meet the stringent requirements of the food industry for hygiene and corrosion resistance.

Pharmaceutical industry: It can reliably transport pharmaceutical raw materials, powders, granules and preparations vertically to ensure the quality and purity of products.

Chemical industry: used for vertical transportation of chemical raw materials, powders, granules and pigments and other materials. The corrosion resistance of the stainless steel material allows it to handle a wide range of chemicals while maintaining operational safety and product quality.

Agricultural field: Materials such as grain, seeds and feed can be raised from the ground into storage or processing equipment without causing damage to crops.

Stainless steel Z type bucket elevator application video display

Advantages of Stainless steel Z type bucket elevator

1.Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for applications in industries such as food processing, pharmaceuticals, and chemicals. It can withstand exposure to moisture, chemicals, and harsh environments without rusting or deter iorating, ensuring long- lasting performance.

2.Hygienic Design: Stainless steel is easy to clean and sanitize, making it ideal for industries with strict hygiene requirements, such as food and pharmaceuticals. The smooth surface of stainless steel prevents the accumulation of dirt, bacteria, and pollutants , ensuring compliance with Hygiene standards and facilitating easy cleaning procedures.

3. Low crushing rate: The Z-type bucket elevator adopts the inflow feeding method, which is not a traditional digging feeding method, and the material crushing rate in the whole process is low. It is suitable for vertical lifting of various fragile or non-fragile materials, such as Melon seeds, peanuts, nuts, rice, corn, potato chips, etc., the lifting height can reach 100 meters, and the conveying capacity is 3~100 cubic meters per hour.

4. Flexible layout: The hoist has the characteristics of horizontal and vertical conveying. There is a material inlet at the lower end, and the material outlet is located at the upper end. The feed port is generally equipped with a feeding device, such as an electromagnetic vibrating feeder, which can be used for the feeder of the weighing packaging machine, the feeder of the color sorter, and the multi-point feeding of the automatic weighing and batching system. The Z-type bucket elevator equipment meets the feeding needs of multiple silos, saving customers' equipment purchase costs.

5.Durability and Strength: Stainless steel is known for its strength and durability, allowing the Z-type bucket elevator to withstand heavy loads and intense operational conditions. It can handle abrasive materials without significant wear and tear, ensuring reliable and continuous operation over an extended period.

Product Specifications

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need6 |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Solutions by Industry

Here are three customer cases that showcase the application of stainless steel Z type bucket elevators in different industries:

-

Food processing industry

Client: Food Processing Company

Application: A food processing company in the United States installed a stainless steel Z-type bucket elevator on its production line for vertical conveying of various food raw materials such as grains, nuts and spices. Stainless steel construction ensures hygiene standards and is corrosion resistant. The Z-shaped design gently handles delicate foods, maintaining their quality and integrity throughout the vertical conveying process.

-

Pharmaceutical industry

Client: Pharmaceutical company

Application: An Italian pharmaceutical company used a stainless steel Z-bucket elevator in its manufacturing plant for the vertical transportation of pharmaceutical powders and granules. The stainless steel construction meets the strict hygiene requirements of the pharmaceutical industry and prevents cross-contamination. The Z-shaped configuration facilitates efficient and controlled material transfer, ensuring precise dosing accuracy and maintaining product integrity.

-

Recycling industry

Client: Recycling Solutions

Application: A stainless steel Z-bucket elevator is used at a recycling plant in Australia to vertically lift and transfer recyclable materials such as plastic bottles and waste paper. Stainless steel construction provides durability and corrosion resistance, allowing the elevator to efficiently handle a variety of materials. The Z-shaped design allows for smooth and efficient material flow, optimizing the recycling process and increasing overall productivity.