Stainless steel bucket elevator

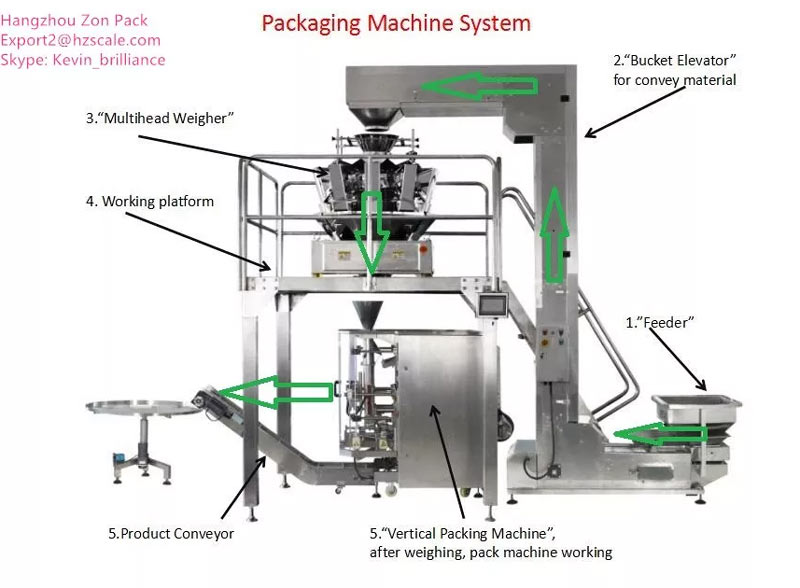

It is specially used for vertically lifting bulk food raw materials or finished products in the food processing industry, and can also lift packaged food into the packaging machine.

Machine shell material: 304 or 316L food grade stainless steel

Hopper material: food grade ABS

Hopper volume: 1.8L, 4.0L and 6.0L (can be customized)

Lifting height: 2-12m

Conveying speed: 2-5m³/h

Conveying capacity: 3-10m³/h

Inlet and outlet: single or multiple

Introduction

Stainless steel bucket elevator refers to a type of bucket elevator that is constructed using stainless steel material for its components, including the buckets, chains, and casings. Stainless steel is chosen for its excellent corrosion resistance, hygienic properties, and durability, making it suitable for various industries, especially those requiring strict cleanliness standards and handling corrosive materials.

Stainless steel bucket elevators are mainly used in industries that require a high degree of corrosion resistance and hygiene requirements. It has excellent corrosion resistance, hygiene and durability, and is suitable for food processing, medicine, chemical industry and other fields. Stainless steel bucket elevators are easy to clean and maintain, providing long-lasting performance and reliable material handling.

Product Display

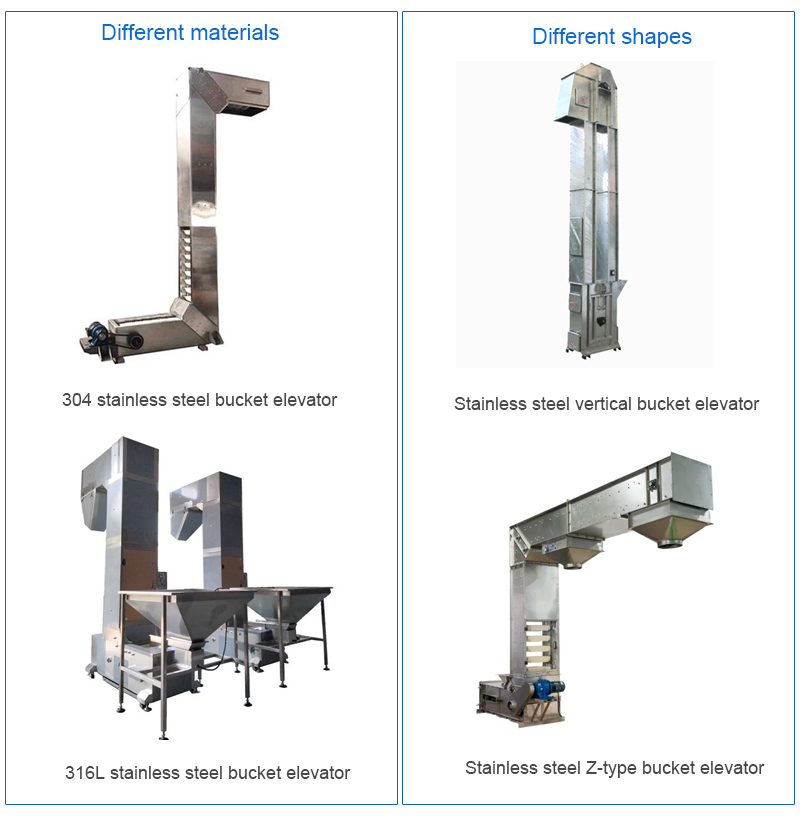

Types of stainless steel bucket elevator

1. Different materials

304 stainless steel bucket elevator: has good corrosion resistance and mechanical properties, and is suitable for lifting materials in general corrosive environments.

316L stainless steel bucket elevator: Based on 304 stainless steel, molybdenum element is added, which has higher corrosion resistance and is suitable for more severe corrosive environments, such as chemical industry, marine and other industries.

2. Different shapes

Stainless steel vertical bucket elevator: It is suitable for occasions where materials need to be lifted vertically. It has a compact structure and takes up little space.

Stainless steel Z-type bucket elevator: suitable for occasions where materials need to be transported in horizontal and vertical directions, and suitable for fragile and fragile products, such as snacks, potato chips, etc.

Applications

Stainless steel bucket elevators are widely used in many industries due to their corrosion resistance and easy cleaning. Here are some of the main applications:

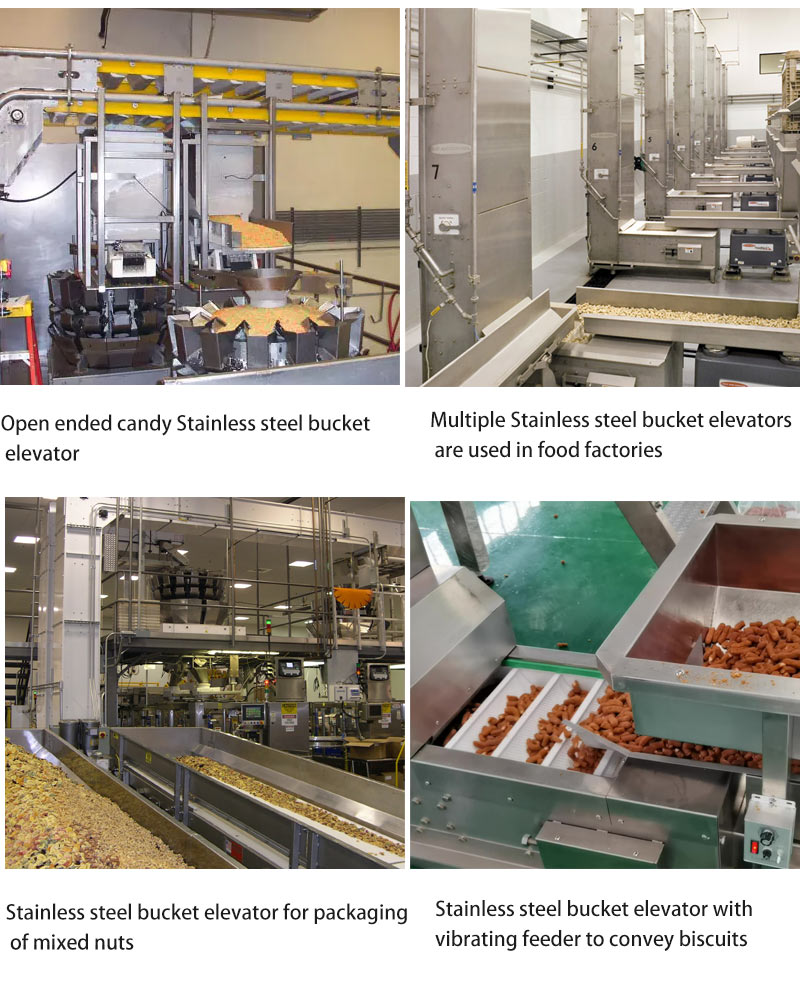

1. Food processing industry

Grain and feed transportation: used to lift grains such as wheat, corn, beans, etc. to ensure the safety and hygiene of materials during processing.

Sugar and salt transportation: in sugar factories and salt factories, refined sugar and salt are lifted to prevent pollution.

2. Pharmaceutical industry

Drug raw material transportation: used to lift drug ingredients and excipients to ensure the cleanliness of the production environment.

Powder and granular materials: suitable for conveying various medicinal powders to meet strict hygiene standards.

3. Chemical industry

Chemical raw material handling: used to lift chemical powders and granules to prevent materials from contacting with air and reduce pollution.

Corrosive materials: stainless steel can resist chemical corrosion and is suitable for handling a variety of chemicals.

4. Agriculture and feed production

Feed raw material transportation: used to lift various feed ingredients to ensure the hygiene and safety of feed.

Seed handling: during seed processing and packaging, seeds are lifted to avoid damage.

Video

Why Stainless Steel?

The main reasons for choosing a stainless steel bucket elevator are as follows:

1. Corrosion resistance: Stainless steel has excellent corrosion resistance and can resist the erosion of various chemical substances. It is suitable for working in humid and corrosive environments, such as chemical, food and other industries.

2. Hygienic performance: Stainless steel has a smooth surface, is easy to clean, non-toxic and odorless, and meets food-grade hygiene standards. Therefore, it is suitable for use in food, medicine and other industries to ensure the hygiene and safety of products.

3. Strength and durability: Stainless steel has good mechanical properties, high strength, wear resistance, long service life, and can maintain a stable working state in harsh working environments.

4. Beautiful appearance: Stainless steel has a metallic luster and a beautiful appearance, which can improve the overall quality and appearance of the equipment.

Therefore, choosing a stainless steel bucket elevator can ensure the stability, durability and hygienic performance of the equipment in a specific working environment, which is a superior performance choice.

Product advantages

1. SS304 or 316L stainless steel material, the hopper is made of food-grade ABS material, which is safe and pollution-free and meets food standards

2. Gentle conveying to avoid damage caused by mutual extrusion of materials

3. It can cooperate with the vibrating feeder to realize automatic and uniform feeding, and the pipeline program conveys

4. The hoisting equipment with the smallest footprint under the same conveying capacity can flexibly adapt to the layout of the factory

5. Able to match the number of original feeding equipment and packaging equipment in the factory, and design multiple inlet and outlet ports

Product Specifications

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need6 |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

product structure

Stainless steel bucket elevator is mainly composed of casing, conveyor chain, hopper, driving wheel, steering wheel, tensioning device, guiding device, material inlet, material outlet, etc.

Hopper: Food grade reinforced polypropylene

Hopper volume: 0.8L, 2L, 4L, 10L

Frame: SS304/316 stainless steel

Silo: 80L/120L

Motor for driving the sprocket: motor optional 220V/380V/415V, 50Hz/60Hz

Storage hoppers and vibrating feeders: small or large volume hoppers

Electric control box: start, stop, emergency stop, vibration control, speed control, signal interface with other machines.

Discharging method

Stainless steel bucket elevator is a commonly used continuous conveying equipment, widely used in chemical, food, building materials and other industries. According to different unloading methods, it can be divided into single-point unloading and multi-point unloading.

Single-point unloading: The material is only unloaded at a fixed position on the top of the elevator, which is suitable for occasions with small material conveying volume and concentrated unloading points.

Multi-point unloading: The material can be unloaded at multiple preset positions during the operation of the elevator, which is suitable for occasions with large material conveying volume and need to be divided at different positions.

| Comparison between single point unloading and multi-point unloading | ||

| Difference | Single point unloading | Multi-point unloading |

| Unloading method | Single fixed location | Multiple preset locations |

| Structural complexity | Simple | Complex |

| Cost | Low | High |

| Scope of application | Small material conveying volume, concentrated unloading point | Large material conveying volume, need for material separation |

| Flexibility | Low | High |

Solutions by Industry

-

Snack manufacturing company

A snack manufacturer uses stainless steel bucket elevators to transport different types of snacks (such as potato chips, puffed foods, candies, etc.) from the raw material area to the processing line. The stainless steel material ensures hygiene and corrosion resistance, while providing reliable material transfer to ensure product quality and food safety.

-

Potato chip factory

In the potato chip manufacturing process, stainless steel bucket elevators are used to transport washed and sliced potatoes to the pre-frying area. This kind of elevator can lift potato slices vertically efficiently and stably, maintaining the integrity and quality of the product. It is also easy to clean and maintain, and meets food hygiene requirements.

-

Nut processing plant

A nut processing plant uses stainless steel bucket elevators to lift raw nuts from the receiving area to the processing line. The stainless steel elevator ensures hygienic handling of nuts, and its corrosion resistance ensures long-term and stable operation. The design of the bucket elevator makes nut transportation efficient and smooth, reducing material loss and fragmentation. Send feedback