TH bucket elevator

It adopts mixed or gravity unloading and bucket loading. The hoist traction part adopts high-quality alloy steel high-link chain, which is used to transport powdery, granular, small-block materials (material temperature is below 250℃), such as coal, cement, gravel, sand, fertilizer, grain, etc.

Traction chain: round link chain

Bucket type: ZH deep bucket, SH deep bucket

Bucket width: 160-1250mm

Transport capacity: 35-185m³/h

Lifting height: 6-40 meters

Product Introduction

TH bucket elevator is a ring chain bucket elevator. Compared with conventional bucket elevators, the receiving part of the bucket is a chain, which replaces the original belt drive. Forged ring chains are used as traction components. It is a hybrid or Gravity unloading, digging loading, large lifting capacity and stronger lifting capacity.

TH bucket elevator models include TH160, TH200, TH300, etc. There are two types of hoppers used: ZH deep hopper is generally suitable for conveying moist, easy to clump, and difficult to throw materials, such as wet sand, molding sand, fertilizer, alkaline fertilizer, alkali powder, etc.; SH deep hopper is generally suitable for conveying dry, loose, and easy to throw materials, such as cement, gravel, coal, etc.

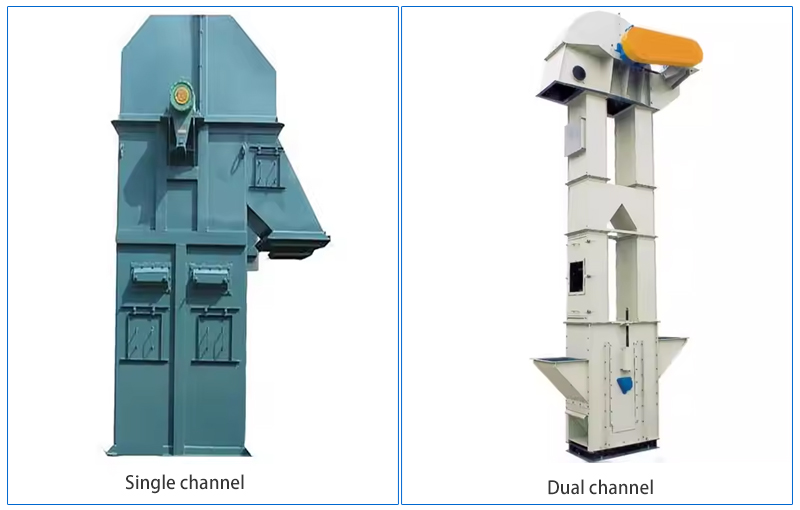

Types of TH bucket elevator

TH bucket elevator can be divided into two types: single channel and dual channel.

Single channel TH bucket elevator: There is only one vertical channel inside for conveying materials. This design is suitable for occasions where vertical conveying is required, and can effectively convey materials from the bottom to the top.

Dual channel TH bucket elevator: Contains two vertical channels, usually designed to be symmetrically arranged. This design can improve the conveying efficiency of the elevator and reduce operating resistance. It can also be used in situations where a larger processing capacity is required. Under the same conditions, the lifting capacity of the dual channel design is 30% higher than that of the single channel.

Features

1. The temperature of the conveying material can reach 250°C, the lifting height is stable and reliable, the noise is low, and the maintenance is convenient.

2. The middle casing has two forms: single channel and double channel. The conveying capacity of the hoist of the improved model is more than 30% higher than that of the ordinary model.

3. The two forms are automatic tensioning with constant force in the weight box inside the machine. The sprocket adopts a replaceable rim combined structure. Long service life and easy replacement of the rim.

4. The lower part adopts a gravity automatic tensioning device, which can maintain a constant tension and avoid slipping or detachment. At the same time, the hopper has a certain tolerance when it encounters a jamming phenomenon caused by accidental factors, which can effectively protect the lower shaft and other components.

Video

Product Model Parameters

| model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| 料斗形式 | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| delivery volume m³/h | normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper form | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | normal type | 500 | 512 | 688 | ||||||||||||||

| Improved | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch) mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| ring number | normal type | 9 | 7 | 7 | ||||||||||||||

| Improved | - | 5 | 5 | |||||||||||||||

| Hopper running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Primary sprocket pitch circle diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Material* bulk mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

product structure

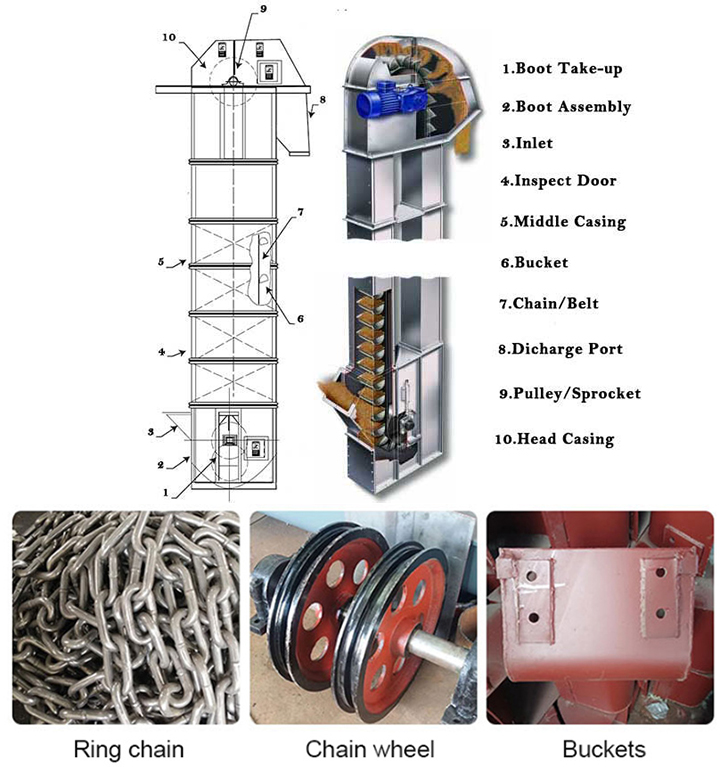

The structure of TH bucket elevator mainly includes the following parts:

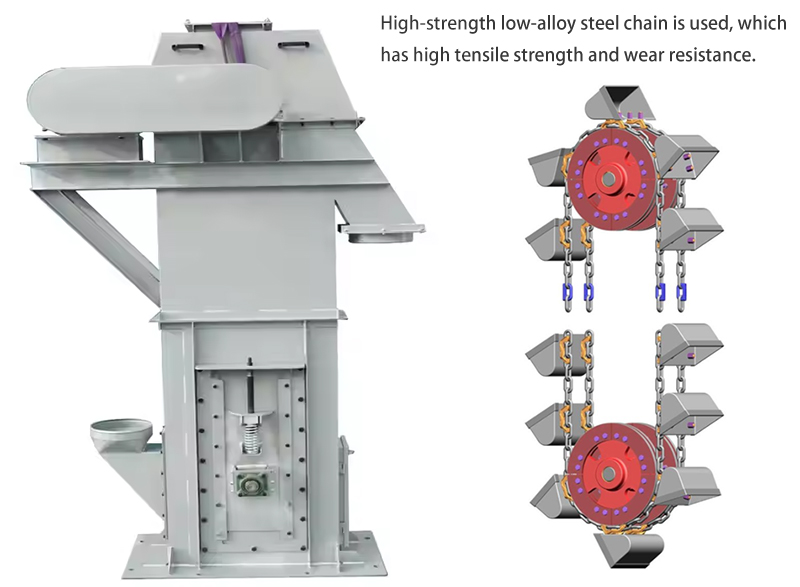

Traction member: T uses forged ring chain as traction member. This chain has been heat treated and has high tensile strength and wear resistance.

Bucket: used for loading and conveying materials, usually using mixed or gravity unloading methods.

Transmission device: The transmission device includes two types, TZ type and YY type, using ZJ type reducer and ZLY, ZSY type reducer respectively.

Tensioning device: The middle casing is divided into single and double channel types, using a heavy hammer box constant force automatic tensioning device to maintain constant tensioning force to avoid slipping or chain off.

Tail device: The tail adopts a heavy hammer lever tensioning device to achieve automatic tensioning, ensure the normal operation of the machine, and avoid slipping or chain off.

Sprocket: The sprocket adopts a replaceable wheel rim combined structure for easy maintenance and replacement.

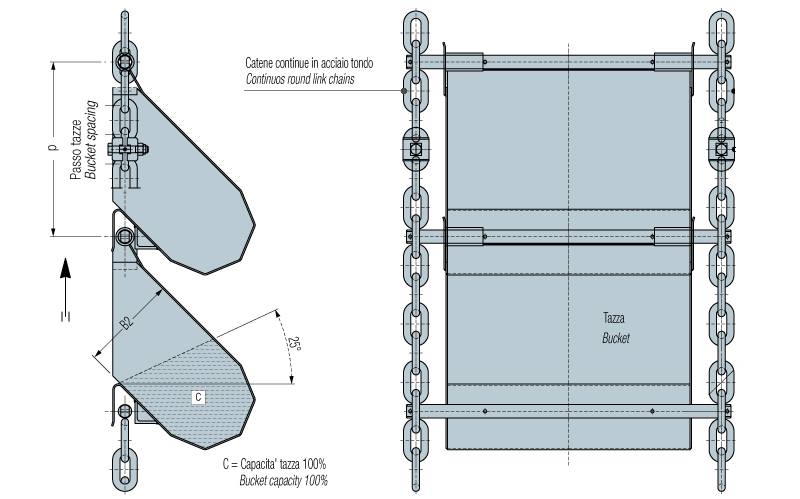

Configuration

TH bucket elevators have two round steel continuous chains connecting the bucket and the drive sprocket. The chains are located on both sides of the bucket to ensure a center discharge aligned with the elevator.

Acceptable material size (mm): Maximum 350

Recommended speed (m/s): 0.20 – 0.50

Acceptable center distance (m): 40

Applications

TH bucket elevator is mainly used for vertical conveying of bulk materials, such as granular or powdered materials.

Grain processing industry: conveying granular materials such as grains, oatmeal, corn, etc., for lifting, unloading and distributing these raw materials.

Chemical industry: used for conveying powdered or granular raw materials such as fertilizers, plastic granules, pigments, iron oxide, etc., for vertical conveying during mixing, processing or packaging.

Building materials industry: used for conveying granular or powdered building materials such as cement, lime, sand, gravel, etc., for material conveying in processes such as mixing stations and mortar production lines.

Mining industry: used for conveying granular materials such as coal, ore, slag, etc., for lifting and processing raw materials or finished products.

Food processing industry: used for conveying food raw materials such as rice noodles, flour, powdered sugar, and grains, for vertical conveying on mixing, packaging or processing lines.

Livestock and poultry farming industry: used for conveying granular or powdered materials such as feed and feed additives, for raw material conveying on feed production lines.