Z Type Conveyor

Increase the horizontal feeding and discharging conveying section to cooperate with the upstream and downstream feeding equipment of the production line and the belt conveying machine of other conveying or packaging equipment.

Delivery angle: 0-90°

Belt width: 300-1500mm

Belt speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Belt material: food grade PVC, PU, rubber

Bracket material: stainless steel/carbon steel/aluminum

product description

Z Type Conveyor is a kind of conveying equipment commonly used in food processing plants. It is usually used in conjunction with feeders, packaging machines and other equipment. It consists of a horizontal section at the inlet and outlet and a 20-90° inclined conveying section in the middle. The material is transported to the packaging equipment upstairs or on the operating table. The design of the upper and lower horizontal sections can make it better receive materials, realize multi-point feeding and connect material receiving equipment more flexibly.

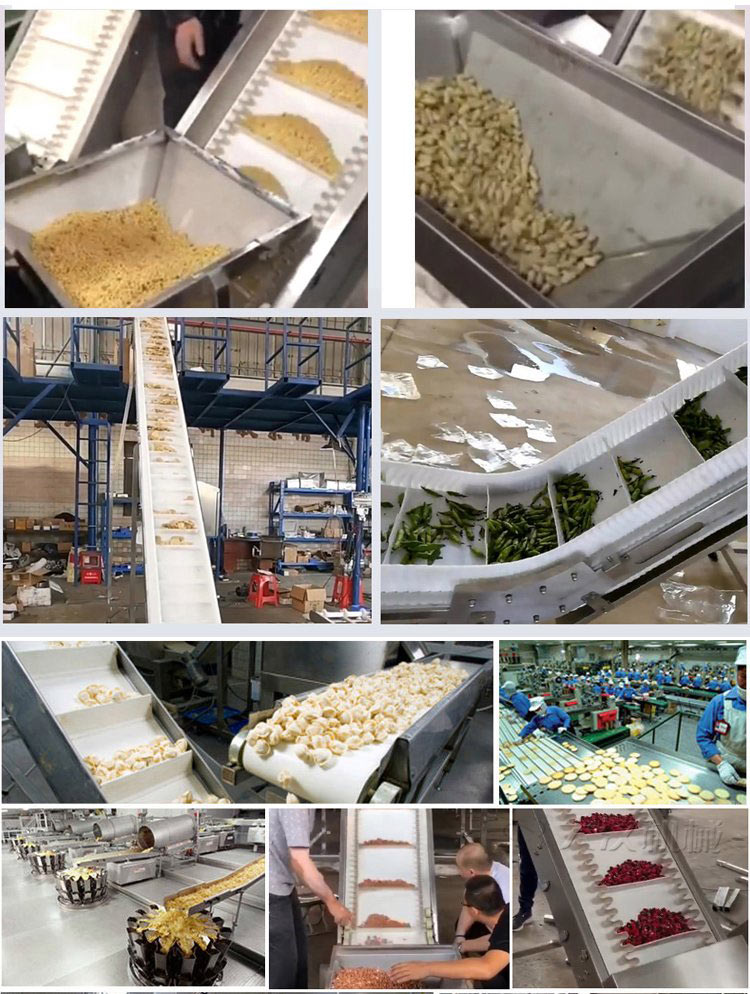

Applications

Due to the compact layout of modern factories and their own characteristics, the conveying system is required to function in the smallest space. The Z Type Conveyor has a compact structure and takes up less space, and the existence of horizontal sections reduces the increase of additional horizontal conveying equipment and reduces equipment purchase costs. , so Z Type Conveyor can be frequently seen in production lines such as fruit and vegetable conveying and pastry conveying.

Product advantages

1. It is used for large inclination or vertical conveying of bulk materials, and the conveying angle is 20-90° (preferably below 70°).

2. It can continuously transport materials below 500 kg, and has strong adaptability to differences in transport environments.

3. The Z-type belt conveyor has corrugated walls and transverse partitions, so it is not easy to scatter when conveying materials.

4. This machine can realize one or more times of controlled feeding, and can be easily connected with various feeding devices.

Viedo

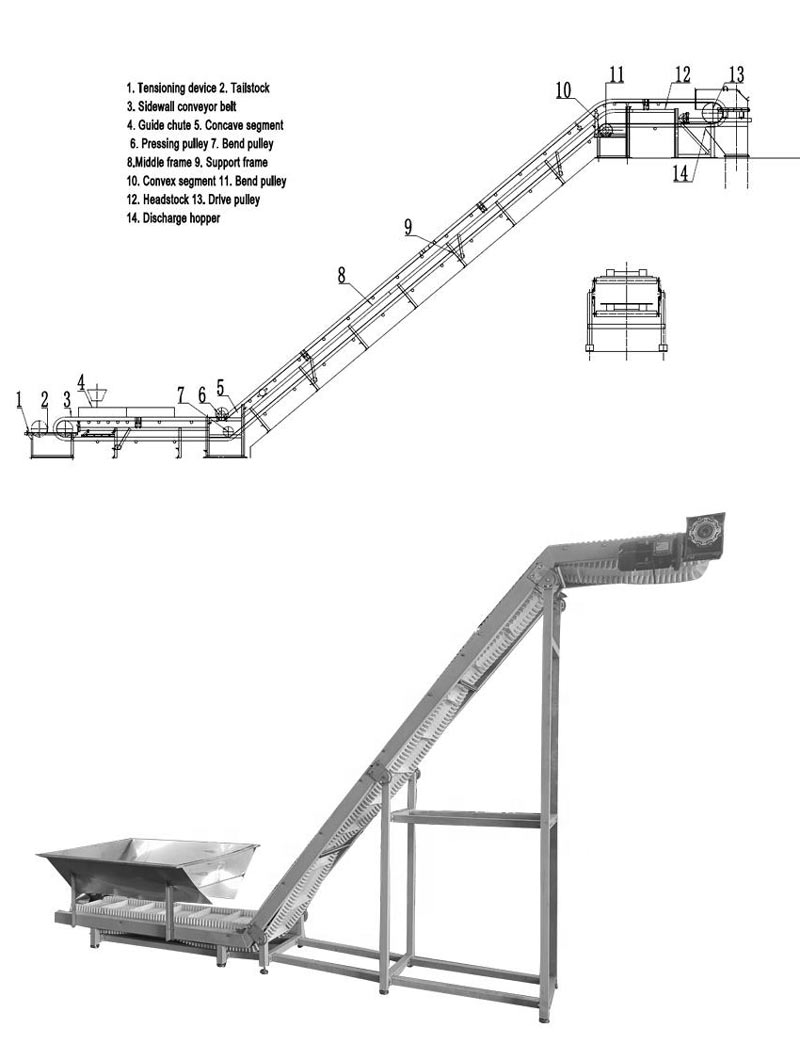

product structure

Z Type Conveyor has a "Z"-shaped structure as a whole, mainly composed of an upper horizontal section, an inclined section and a lower horizontal section.

1. Lower horizontal section: Low-type middle frame legs are used for stable loading during loading, reducing the pressure on the conveyor during loading and reducing material scattering.

2. Inclined section: the horizontal section adopts low, medium and high intermediate frame legs, and the inclined section adopts low intermediate frame legs. When the conveyor inclination angle is greater than 45°, it is recommended to use low-type intermediate frame legs.

3. The upper horizontal section: it is the discharge end. According to the discharge requirements of different heights, the height of the head frame used is different, and the legs of the middle frame need to be matched according to the head frame.

product details

1. Self-contained silo, combined with feeding equipment, increases the upper limit of feeding amount;

2. The side baffle belt, the inclined conveying material will not slide down or scatter, ensuring the conveying efficiency;

3. Stainless steel metal bracket, stable structure, not easy to wear and corrosion, long service life;

4. The belt is supported by stainless steel plates, which has stronger pressure bearing capacity and is not easy to crack.

Product number

| Belt Width B (mm) | 400 | 500 | 650 | 800 | 1000 | 1200 | 1400 | |||||||||

| High guard H (mm) | 60 | 80 | 80 | 120 | 120 | 160 | 160 | 200 | 160 | 240 | 200 | 300 | 240 | 400 | ||

| minimum horizontal baffle spacing | 100 | 120 | 120 | 160 | 160 | 200 | 200 | 250 | 200 | 280 | 250 | 350 | 280 | 400 | ||

| Throughput | 30° | 28 | 36 | 50 | 71 | 104 | 120 | 157 | 195 | 216 | 327 | 331 | 466 | 500 | 794 | |

| (raw coal,idling 1m/s) | 45° | 19 | 25 | 33 | 57 | 83 | 97 | 127 | 157 | 175 | 271 | 267 | 384 | 414 | 680 | |

| M³/h | 60° | 15 | 19 | 23 | 40 | 58 | 69 | 90 | 112 | 124 | 197 | 190 | 278 | 302 | 524 | |

| 90° | 9 | 11 | 15 | 21 | 31 | 37 | 48 | 60 | 66 | 106 | 102 | 149 | 162 | 281 | ||

| Overall dimensions | High head belting leather surface H1 | |||||||||||||||

| 1200 | 1350 | 1615 | 1815 | 2000、2200 | 2300、2525 | 2525、2700 | ||||||||||

| High end belting leather surface H2 | ||||||||||||||||

| 690 | 800 | 950 | 1115 | 1250、1400 | 1600、1700 | 1600、1700 | ||||||||||

| High middle section of belt surface H3 | ||||||||||||||||

| 700 | 800 | 850 | 1115 | 850、1200 | 1400、1500 | 1600、1700 | ||||||||||

| middle period of anchor wide B1 | ||||||||||||||||

| 580 | 850 | 1020 | 1220 | 1440 | 1690 | 1890 | ||||||||||

Industry Solutions