Z Type Bucket Elevator

The material is conveyed through the hopper suspended on the chain, which can be combined horizontally-vertical-horizontal conveyance

Machine type: Z type, C type and multiple feed ports, multiple discharge ports

Hopper capacity: 1L, 1.8L, 3.8L and 6.5L

Horizontal length: 1.2m-40m

Vertical height: 1.5-30 meters

Introduction of Z Type Bucket Elevator

The Z type bucket elevator adopts stainless steel or carbon steel plastic-sprayed shell. The horizontal length of the feeding port is 1.2 meters to 40 meters, and the vertical height is 1.5 to 30 meters. Used to handle powder, bulk solids or brittle, brittle materials, usually used in conjunction with weighing packaging machines and color selection machines on automatic production lines.

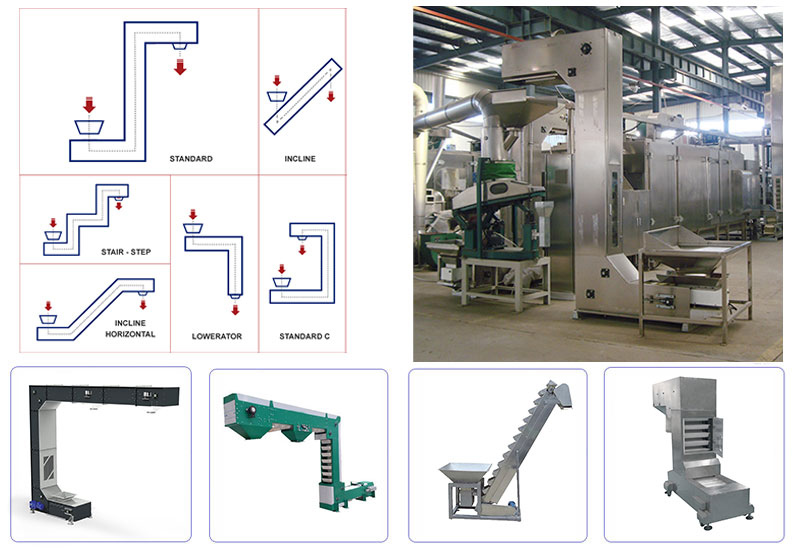

Types of Bucket Elevator Conveyor

Flexible layout: z-type feeding, c-type feeding, z-c-type mixed feeding, multi-point feeding, multi-point unloading

The Z type bucket elevator can be combined horizontally-vertically-horizontal conveying, can be single-point or multi-point feeding, and can complete single-point or multi-point unloading through the unloading device, which can be used for the feeding of the weighing packaging machine packaging machine, The feeder of the color sorter is used for multiple feeding, and the multi-point feeding of the automatic weighing and batching system can be widely used in various environments that require gentle processing.

-

Multi-feed Z Type Bucket Elevator

The multi-feed Z-type bucket elevator can be used with multiple feeding systems such as feeder, weighing system, and color sorting system to realize simultaneous feeding of multiple products and adapt to the layout of the original feeding equipment.

-

Multi-outlet Z Type Bucket Elevator

In the case of feeding a large amount of bulk materials, it can simultaneously feed materials to multiple packaging equipment, mixing equipment or other equipment to improve production efficiency.

-

Stainless Steel Z Type Bucket Elevator

The Stainless steel Z type bucket elevator is made of 304 or 316L stainless steel for the machine shell, and the hopper is made of PP for food, and is mostly used for bulk material lifting and conveying in the food and pharmaceutical industries.

Features and Benefits

The Z type bucket elevator integrates the horizontal conveying and lifting of materials. One hoist can replace the three traditional horizontal conveying + lifting + horizontal conveying equipment. Has the following characteristics:

1. Gentle conveying will not damage fragile granules, flakes and other materials, and has a good lifting effect on light specific gravity, irregular and fragile materials.

2. The horizontal length is 1.2-40 meters, and the vertical height is 1.5-30 meters, which can be customized according to the user's on-site design.

3. It can be single-point or multi-point automatic unloading, which is suitable for feeding multiple silos in a row.

4. The hoppers are densely arranged, and the shell of the whole machine is sealed, which is not easy to spread materials, and reduces the dust flying caused by material leakage during operation.

5. The assembled sprocket is adopted. The wheel body and the wheel rim are connected by high-strength bolts. After the sprocket is worn to a certain extent, the bolts can be unscrewed and the rim can be removed and replaced, which is convenient for replacement, saves materials and reduces maintenance costs.

6. The lower part adopts a heavy hammer lever type tensioning device, which can realize automatic tensioning. No adjustment is required after a single installation, and a constant tension can be maintained, thereby ensuring the normal operation of the machine and avoiding slippage or off-chain.

7. The traction part is a low-alloy high-strength circular chain. After proper heat treatment, it has tensile strength and wear resistance, and has a long service life.

The difference between Z-type bucket elevator and other bucket elevators

>| Main points | Z type bucket elevator | Other bucket elevators |

| shape | Diverse shapes, Z type, C type, ZC mixed type and other designs are available | No horizontal section, directly lift materials vertically |

| Inlet and outlet | Multiple designs possible | Single near inlet and outlet |

| delivery status | The material is fed directly, soft and stable, without collision friction | Inflow feeding induction discharge, easy to damage the shape of the material |

| Application industry | Mostly used in food light industry | It is mostly used in mining, chemical industry and building materials industry |

| lifting height | The length of the horizontal section is 1.2-10m, and the vertical section can be lifted by 1.5-12m | Vertical lifting height up to 40m |

The difference between Z-type bucket elevator and belt and screw conveyor

>| Main points | Z type bucket elevator | Belt conveyors | screw conveyor |

| space occupied | In the case of the same lifting height, the space occupied is small | Under the same lifting height, the space occupation is the largest | Under the same lifting height, the space occupation is the smallest |

| handling materials | Granules, powders, chunks, irregular, fragile products, virtually unlimited | Large particles, lumps, irregular or packaged products | Small particles or powder bulk |

| acquisition cost | higher | lower | higher |

| product structure | relatively complex | relatively simple | relatively complex |

| improving capability | Can achieve ≤12m vertical lifting | It is mostly used for tilt lifting less than 60° | Can achieve ≤8m vertical lifting |

Application video

Lightweight Z Type Bucket Elevator with Vibratory Feeder for Coffee Bean Delivery

Z Type Bucket Elevator Conveying Flour

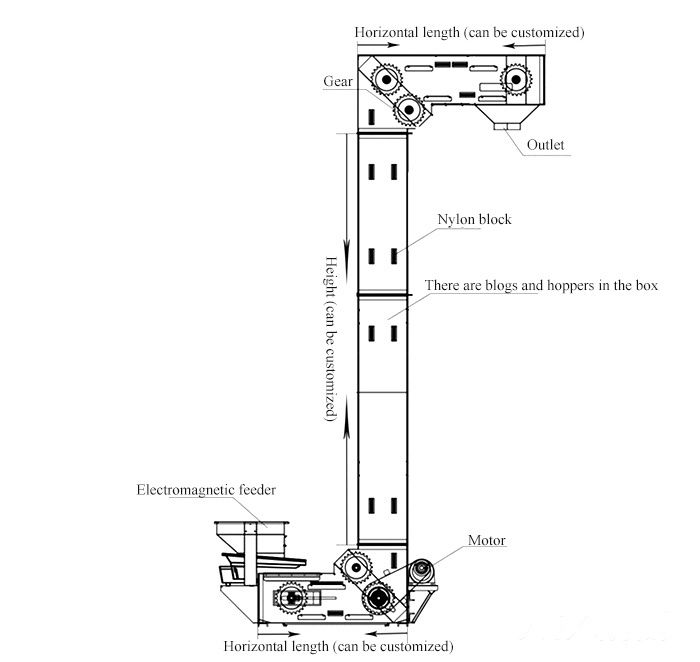

Structure of Z Type Bucket Elevator

Z type bucket elevator is mainly composed of shell, conveyor chain, hopper, driving wheel, redirecting wheel, tensioning device, guiding device, feeding port, discharging port and so on.

Options:

Chassis: semi-enclosed chassis - dust-proof chassis - airtight chassis - stainless steel chassis - carbon steel spraying chassis.

Hopper: stainless steel hopper - carbon steel hopper - food grade plastic hopper.

Drive: explosion-proof reducer, ordinary reducer.

Sprockets: Alloy steel sprockets - stainless steel sprockets.

Chain: Alloy steel chain - stainless steel chain.

Control: Manual start and stop, automatic start and stop, frequency conversion control.

Others: The whole machine is explosion-proof, built-in forced ventilation system, automatic hopper cleaning system, automatic refueling system.

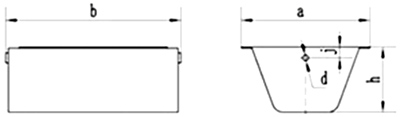

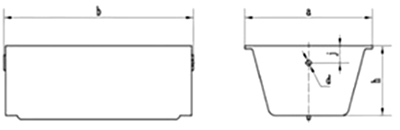

Optional hopper:

Hopper volume: 1L, 1.8L, 3.8L and 6.5L

Hopper material: ABS/PP/SUS304

Applicable situation: ABS viscous moisture, high temperature material conveying choice

PP food grade plastic, common product delivery option

SUS304 high temperature, corrosion, abrasive material conveying choice

| Item |

Width (mm) |

Volume (L) |

Size | CH3-10 Drawing | |||

| a | h |

d (H12) |

j | ||||

| CH3 | 370 | 3 | 235 | 120 | Φ13 | 20 |

|

| CH6 | 470 | 6 | |||||

| CH10 | 870 | 10 | |||||

| CH15-35 Drawing | |||||||

| CH15 | 500 | 15 | 340 | 195 | Φ12 | 45 |

|

| CH20 | 560 | 20 | |||||

| CH25 | 690 | 25 | |||||

| CH30 | 815 | 30 | |||||

| CH35 | 940 | 35 | |||||

Technical parameters

| Model | ZD-3 | ZD-6 | ZD-10 | ZD-15 | ZD-20 | ZD-25 | ZD-30 | ZD-35 | ||

| Delivery volume | 100% | m³/h | 6 | 15 | 22 | 30 | 45 | 56 | 68 | 80 |

| 75% | 4.5 | 11 | 16.5 | 22.5 | 33.5 | 42 | 51 | 60 | ||

| Hopper | Dou Rong | L | 3 | 6 | 10 | 15 | 20 | 25 | 30 | 35 |

| Bucket width | mm | 370 | 470 | 870 | 500 | 560 | 690 | 815 | 940 | |

| Bucket distance | mm | 228.6 | 330 | |||||||

| Chain | Pitch | mm | 38.1 | 66 | ||||||

| Number of bars | —— | 2 | ||||||||

| Single chain breaking load (kv) (minimum) | —— | 37.6 | 90 | |||||||

| Sprocket | Number of teeth | —— | 26 | 22 | ||||||

| Pitch diameter | mm | 316.09 | 463.75 | |||||||

| Hopper running speed | m/s | ≤0.3 | ≤0.25 | |||||||

| Drive shaft speed | r/min | ≤0.3 | ||||||||

| Maximum lift height | m | ≤4.5 | ||||||||

| Maximum horizontal conveying distance | m | ≤100 | ||||||||

| Total power | KW | 0.75~22 | 1.1~22 | 2.2~22 | 5.5~22 | 5.5~30 | ||||

Application

Z type bucket elevator is an auxiliary machine of packaging machine, mainly used for conveying solid and granular materials.

Food industry: biscuits, gummies, marshmallows, small steamed buns, pancakes, chicken essence, milk tea, jelly, shrimp chips, potato chips, rice noodles, rice balls, dumplings, chocolate, peanuts, coffee, sugar, nuts, jelly beans, sunflower seeds , pistachios, walnuts, almonds, rice, millet and other granular powder foods.

Chemical industry: plastic granules, powders (PP, PE, PS), activated carbon, preservatives, additives, fertilizers, etc.

Pharmaceutical industry: pills, capsules, tablets, etc.

Hardware industry: screws, nuts, metal fittings, etc.

Solutions by Industry

-

Multiple feed ports Z Type Bucket Elevator

-

Z Type Bucket Elevator with packing machine

Stainless Steel Z Type Bucket Elevator Lifts and Conveys Chips and Pretzels

Features: Conveying of fragile, irregular and hygienic goods

Advantages: Irregular and brittle brittle food biscuits, gently conveyed using stainless steel Z Type Bucket Elevator, will not damage the integrity of chips and pretzels, guarantee commodity value, while food grade hopper and sealed stainless steel body, It also ensures the hygiene of food delivery.

Z Type Bucket Elevator lifts mixed nut and animal feed to packer

Features: loose, irregular, easy-to-scatter granular commodity transportation

Advantages: Mixed nuts and animal feed pellets have small specific gravity and light weight and are easy to spill during the lifting process. Z Type Bucket Elevator can be used with vibrating feeders and packaging machines to complete the production and packaging work of the assembly line. The hopper of the Z Type Bucket Elevator can fully accommodate nuts and feed and run smoothly without spilling, improving efficiency and high yield.

Z Type Bucket Elevator Multi-point discharging and feeding

Features: The upper and lower horizontal sections of a Z Type Bucket Elevator can be arranged according to the production conditions of your factory, for example, with multiple feeding devices, conveying devices, multiple packaging equipment, multiple production processes, etc. , which can save space to the greatest extent and improve the cost performance.

Professional manufacturer

Dahan Machinery is a Z Type Bucket Elevator manufacturer from China with 15 years of production and operation experience. The product is guaranteed to be delivered within 48 hours, the drawings for special designs are produced within 72 hours, the machine is sold for 1 year free maintenance, and the product quality problem is unconditionally returned within 7 days.

Dahan Machinery has a modern industrial plant of 10,000 square meters, as well as professional production equipment and design and production personnel, focusing on solving various transportation and lifting problems.

How to choose a suitable Z Type Bucket Elevator?

Some selection tips from manufacturers:

1. What bulk materials need to be transported? What is their material and state?

2. How much lifting capacity do you need per hour and what is your feed rate?

3. What is the height of the material conveying to the next process and the distance you expect?

4. What are the design conditions of Z Type Bucket Elevator material, feeding and discharging conditions, working temperature, and the size of the space reserved in the factory?

...

We provide you with professional selection guidance, machine design and thoughtful after-sales service. Consult now for more information.

Frequently Asked Questions

Q1: How long is the actual delivery time of your factory?

A: 10-15 days for general series products, 20-40 days for customized products according to different situations.

Q2: How do you guarantee the quality of the products?

A: Strictly speaking, our brand is quality assurance. We promise that the equipment of Dahan Machinery is the most durable type in the industry. Of course, we do not deny that a small number of products may malfunction or be damaged for different reasons. We are responsible for after-sales protection and maintenance of such products.

Q3: If the product is damaged, how does your after-sales service work?

A: Within 12 months of the guarantee time, we provide after-sales service, and the products can be consulted and maintained for life.