Z type continuous elevator

The Z type continuous elevator realizes cyclic retrieving and feeding work on the specified path through the traction belt or chain hopper.

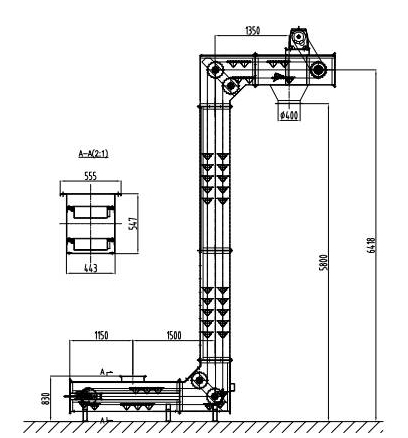

Standard unloading height: 1.5-30m

Standard feed length: ≤1.3m

Standard discharge length: ≤1.3m

Variable speed control: as required

Frame Material: Stainless Steel/Painted Steel

Hopper capacity: 1L, 1.8L, 3.8L and 6.5L

Machine type: Z type, C type and multiple outlets

Product introduction of Z type continuous elevator

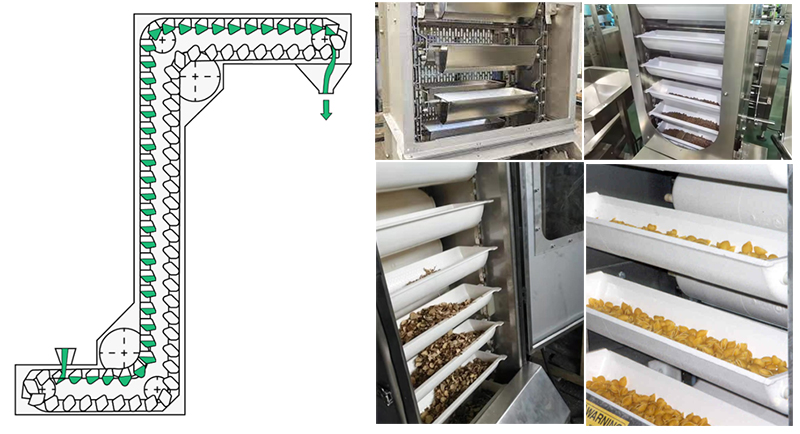

The hoppers of the Z type continuous elevator are arranged tightly and orderly, and the horizontal connection of the hoppers in the feeding section can form a seamless material receiving surface. Bulk materials can flow into the hopper through the feeding equipment, and the hopper is lifted to the top along with the conveyor belt or chain. After passing the top wheel, turn down and dump the material in the hopper into the receiving tank.

The hopper that completes the material conveying work is pulled by the traction belt/chain to run downward, and after passing through the bottom wheel, it turns upward and receives the material again for lifting and conveying, forming a cycle.

Z type continuous elevator optional traction form

Chain traction: Chain is one of the most common traction forms. In a Z type continuous elevator, the chain runs along the driving wheel and driven wheel of the elevator, connecting the buckets or barrels in the bucket elevator together, and realizing vertical transportation of materials through the traction of the chain.

1. The belt is connected in series with the hopper to realize continuous conveying

The use of belt tandem hoppers has more restrictions on the conveyed materials. For example, the temperature of the materials is required to be lower than 150°C, non-abrasive and corrosive, and the load-bearing capacity of the belt tandem hopper is weak, and the lifting capacity is also poor, so it is more suitable for use. It is suitable for lifting materials with light specific gravity in a short distance, but the noise generated by belt traction is the least and the price is relatively low.

2. The metal chain connects the hopper to realize continuous conveying

Metal chains have relatively no restrictions on conveying and lifting. They have a strong load-bearing capacity and can be lifted to a higher height. They can withstand materials at a high temperature of 250°C. The price of metal chains is relatively high, and greater noise will be generated due to metal friction during the conveying process.

Z type continuous elevator application

Z type continuous elevator is mainly used to vertically lift bulk products from a low place to a height not higher than 12m. According to the needs of the actual scene, it can be unloaded at multiple points. The inflow feeding and smooth traction and lifting can reduce the material damage rate to Almost 0%. It can cooperate with material weighing and packaging machine, material color sorter and inspection feeding, automatic production line loading and unloading cycle perspective, multi-point automatic weighing and batching system feeding.

Types of materials processed: potato chips, biscuits, candies, seeds, plastic/rubber granules, grain, white rice, green coffee/coffee beans, wood chips, fodder, flour, etc.

Advantages of Z type continuous elevator

1. Automatically and continuously retrieving and feeding materials to realize the de-manualization of the production process;

2. The hoppers are arranged densely and orderly, and the material receiving end can realize the seamless connection of the hoppers, increase the amount of material received and avoid material leakage;

3. It can realize single-point or multi-point feeding, and cooperate with the production situation of multiple silos;

4. The hopper runs smoothly, the material does not squeeze in the hopper, and the material damage rate is close to 0%.

Videos

Z type continuous elevator model parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

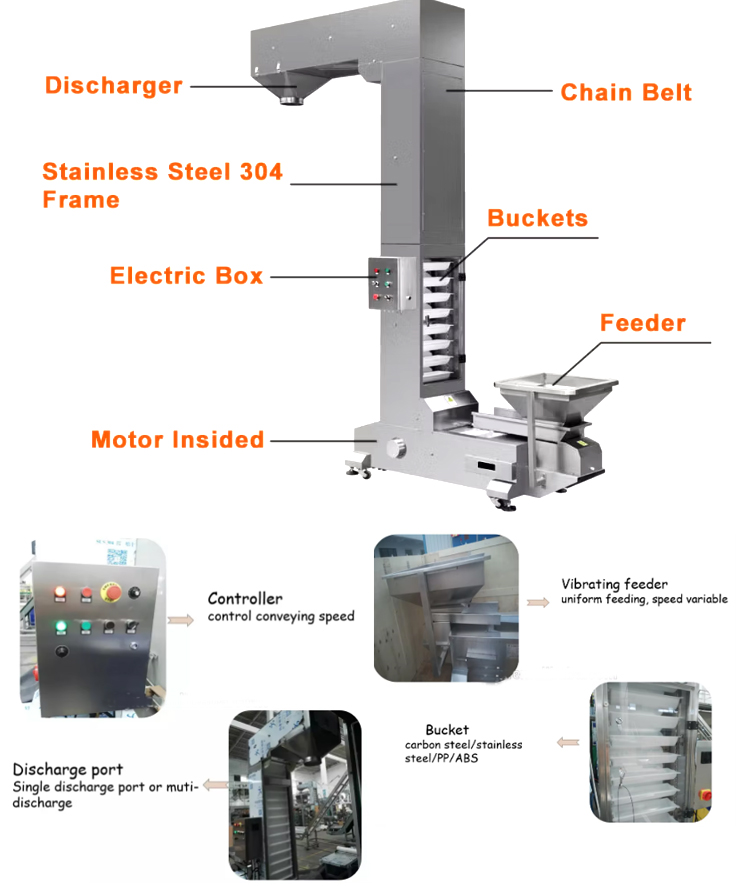

Z type continuous elevator structure

Buckets: These are attached to a continuous belt or chain and are responsible for carrying the material.

Head Pulley: It's connected to a motor and gearbox, which provides the power to drive the belt or chain.

Tail Pulley: It guides the belt or chain and maintains tension.

Truss or Frame: It's typically made of steel and designed to withstand the weight of the material, buckets, and the forces generated during operation.

Chain: This is the continuous loop that carries the buckets.

Hopper: This is the inlet where the material is fed into the elevator. It's designed to ensure a smooth and even flow of material into the buckets.

Discharge Chute: This is the outlet where the material is discharged from the elevator. It's designed to direct the material to the next stage of the process.

Optional Components

Enclosures: To prevent material spillage and dust emissions.

Dust collectors: To capture dust generated during operation.

Vibration dampeners: To reduce noise and vibration.

Safety devices Such as emergency stops and overload protection.

Solutions by Industry