Z type elevator

Z type elevator is mainly used to realize the horizontal and vertical integrated transportation of materials, and it is usually used in combination with packaging machines to minimize the material damage rate.

Conveying Speed: 2-5 m³/h

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

Discharge Height 2-12 m

In-Feed Length: 863 mm

Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Number of Outlet(s):Single or Muti-dicharge outlets

Product introduction of Z type elevator

Z type elevator, also known as a Z-shaped bucket conveyor or Z-bucket elevator, is a specific configuration of a bucket elevator conveyor. It is designed to transport bulk materials vertically with a combination of horizontal and vertical movements.Unlike traditional bucket elevators that move materials in a straight vertical line, the Z type elevator utilizes a series of alternating horizontal and vertical sections to achieve a more compact and efficient design.

Z-type elevators are commonly used in industries such as food processing, pharmaceuticals, and packaging where gentle and efficient vertical transportation is required. They can handle a variety of materials including grains, seeds, nuts, powders, and small products.

Different product designs of Z type elevator

Z type elevator can be horizontal --- vertical ---horizontal combined conveying, single-point or multi-point feeding, and single-point or multi-point unloading can be completed through the unloading device, which can be used for feeding of weighing packaging machine packaging machine, color The machine-selected feeder has re-selected feeding, and the multi-point feeding of the automatic weighing and batching system can be widely used in various environments that require gentle handling.

Videos

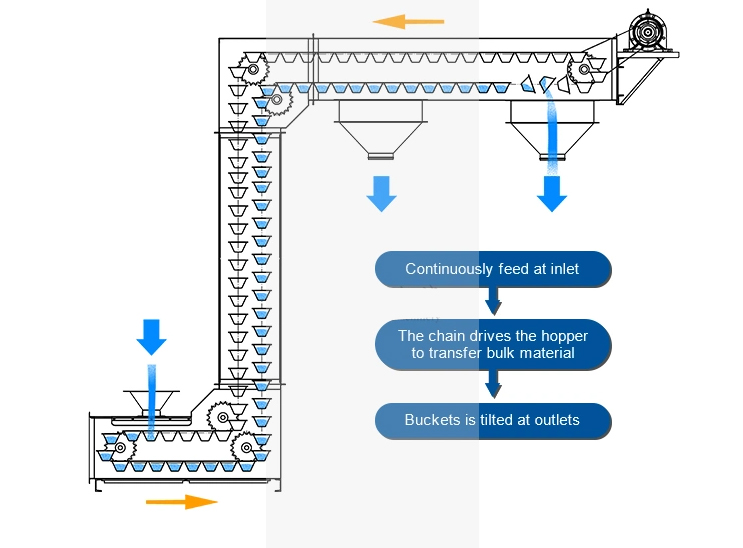

Working principle of Z type elevator

The working principle of a Z-type elevator, also known as a Z-bucket elevator or Z-shaped bucket conveyor, involves the vertical and horizontal movement of buckets to transport bulk materials. Here's an overview of the working principle:

Bucket Loading: The Ztype elevator starts with the buckets positioned at the lower or horizontal section of the elevator.

Material Filling: As the buckets move along the horizontal section of the elevator, they pass through a material inlet or loading point. At this point, the buckets are positioned to scoop or receive the bulk material from a hopper or conveyor chute.

Vertical Conveying: Once the buckets are filled, the elevator starts its vertical movement.

Z-Shaped Path: As the buckets reach the top of the elevator, they turn around the top sprocket or pulley and change their direction from vertical to horizontal.

Material Discharge: Along the horizontal section, the buckets carry the material to the discharge point.

Bucket Return: After the material is discharged, the empty buckets continue their horizontal movement, returning to the lower section of the elevator.

Z type elevator features

1. Wide range of applications

Universal lifting equipment suitable for bulk items (such as granular, shaped and block solid items). Ideal supporting conveying equipment for electronic multi-head scales, vertical packaging machines and other material receiving equipment. Widely used in the field of food packaging.

2. Clean transportation

The hopper of Z type elevator is always kept vertical after conveying the product to ensure cleanliness and easy maintenance. The flat stacking technology at the feeding place eliminates the loss of product leakage due to the interval between the buckets, and the feeding place is clean.

3. Easy to clean

The Z type elevator hopper is made of PP or stainless steel, which meets food hygiene standards. The hopper can be quickly removed and cleaned without any tools. Some designed hoppers can also be machine cleaned.

4. Stable operation

Reasonable structure ensures that the machine will not fall off the hopper at any time. The friction protection system of the power box ensures the normal operation of the machine.

Z type elevator specification

| Model | ZD-3 | ZD-6 | ZD-10 | ZD-15 | ZD-20 | ZD-25 | ZD-30 | ZD-35 | ||

| Delivery volume | 100% | m³/h | 6 | 15 | 22 | 30 | 45 | 56 | 68 | 80 |

| 75% | 4.5 | 11 | 16.5 | 22.5 | 33.5 | 42 | 51 | 60 | ||

| Hopper | Dou Rong | L | 3 | 6 | 10 | 15 | 20 | 25 | 30 | 35 |

| Bucket width | mm | 370 | 470 | 870 | 500 | 560 | 690 | 815 | 940 | |

| Bucket distance | mm | 228.6 | 330 | |||||||

| Chain | Pitch | mm | 38.1 | 66 | ||||||

| Number of bars | —— | 2 | ||||||||

| Single chain breaking load (kv) (minimum) | —— | 37.6 | 90 | |||||||

| Sprocket | Number of teeth | —— | 26 | 22 | ||||||

| Pitch diameter | mm | 316.09 | 463.75 | |||||||

| Hopper running speed | m/s | ≤0.3 | ≤0.25 | |||||||

| Drive shaft speed | r/min | ≤0.3 | ||||||||

| Maximum lift height | m | ≤4.5 | ||||||||

| Maximum horizontal conveying distance | m | ≤100 | ||||||||

| Total power | KW | 0.75~22 | 1.1~22 | 2.2~22 | 5.5~22 | 5.5~30 | ||||

Z type elevator product structure

The key components of a Z type elevator include:

Infeed Section: This is the horizontal section at the bottom of the elevator where materials are fed into the buckets. It typically has a vibratory or feeding mechanism to maintain a steady flow of materials.

Vertical Section: The vertical section consists of multiple Z-shaped segments where the buckets travel upward or downward to transport materials between different levels. The vertical movement is achieved by the continuous loop of a chain or belt that drives the buckets.

Discharge Section: At the top of the elevator, the buckets tip over or open to discharge the materials into a chute, conveyor, or another processing equipment.

Available options

Other details of the machine structure can be selected:

Chassis: semi-closed chassis - dustproof chassis - airtight chassis - stainless steel chassis - carbon steel spraying chassis.

Hopper: stainless steel hopper - carbon steel hopper - food hopper.

Drive: explosion-proof reducer, ordinary reducer.

Sprocket: Alloy steel sprocket—stainless steel sprocket.

Chain: alloy steel chain - stainless steel chain.

Control: manual start and stop, automatic start and stop, frequency conversion control.

Others: The whole machine is explosion-proof, built-in forced ventilation system, automatic hopper cleaning system, automatic refueling system.

Application of Z type elevator

Z-type elevators, also known as Z-type bucket elevators or Z-type bucket conveyors, have a variety of applications in different industries. Here are some common applications of Z elevators:

Food industry: It is used for vertical conveying of bulk food such as grains, miscellaneous grains, rice, nuts, seeds, and snacks. The gentle handling provided by the Z-Lift helps prevent product damage and maintain product integrity.

Agriculture and Planting: Used to move crops including corn, wheat, soybeans and other grains. They are used for vertical transport from one processing stage to another, for example from a cleaning system to a storage box or from a storage box to a packaging line.

Pharmaceutical and chemical industry: Z-type elevators are used for vertical conveying of powdery and granular materials in pharmaceutical and chemical processing plants. They are used to transfer ingredients, additives and raw materials between different production stages such as mixing, blending and packaging.

Recycling and Waste Management: Z-lifts are used in recycling and waste management facilities to transport recyclable materials such as plastic pellets, paper, cardboard and metal scrap vertically to different processing or storage areas. Construction and Mining: The Z elevator is suitable for use in the construction and mining industry for the vertical transport of bulk materials such as sand, gravel, stone and ore. They are used in processes such as loading material into hoppers, storage and feeding to crushers or screening equipment.

Packaging Industry: Z type elevators play a vital role in the packaging industry for the vertical transfer of packaged products or components between different stages of the packaging process. They help ensure smooth and efficient product flow during filling, sealing, labeling and palletizing operations.

Manufacturing and Industrial Processes: Z-Elevators are often integrated into manufacturing and industrial processes involving bulk material handling. They facilitate the vertical movement of materials such as plastic granules, rubber, chemicals and powders between different production stages or storage areas.

Solutions by Industry

Here are three customer cases that showcase the application of Z type bucket elevators in different industries:

-

Customer Story:: food processing industry

Application: A leading snack food producer in Vietnam needed a reliable, efficient solution for the vertical conveying of a variety of snack ingredients, including nuts, seeds and grains. They chose the Z-Bucket Elevator to gently transfer these delicate ingredients without compromising their quality. The Z type elevator provides precise and controlled discharge of material, ensuring minimum product breakage and maintaining required product integrity throughout production.

-

Customer Story:: Agriculture

Scope of application: An agricultural company in the Philippines wanted an efficient solution to transfer grain from the ground to overhead storage bins. They chose the Z-Bucket Elevator because of its ability to handle high-volume vertical conveying. The Z-type elevator can transfer grain smoothly and continuously, optimizing the storage process and reducing manual labor. The bucket design ensures that spillage and dust emissions are minimized, improving operational efficiency.

-

Customer Story: Recycling Facility

Application: A waste management company in France processes a variety of recyclable materials including plastic bottles, paper and cardboard. They needed a solution for efficient vertical transfer of these materials during recycling. A Z-type bucket elevator was installed to transport the recyclate to the different processing stages such as sorting, shredding and baling. The Z-style elevator's robust construction and customizable bucket design can effectively handle different types of recyclable materials, improving overall recycling efficiency.