Z type vertical elevator

Z type vertical elevator carries bulk materials through a continuous hopper to achieve complete vertical lift in a 90° direction.

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

Discharge Height: 2-12 m

In-Feed Length: 863 mm

Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Application: Used in food processing and packaging industries to transport bulk products such as grains, candies, nuts, feed, fertilizers, etc.

Product introduction of Z type vertical elevator

Z type vertical elevator has a more stable and powerful vertical lifting capacity - compared with vertical screw conveyors and inclined belt conveyors.

When the Z type vertical elevator is transporting materials, the hopper carries the materials stably, and the materials are in a relatively static state during the entire lifting process, so the materials will not scatter or slip. At the same time, the hopper of the Z type vertical elevator is connected with a chain as a traction device for lifting, so the hopper runs smoothly and receives stronger traction force, which can vertically lift the material to a higher height.

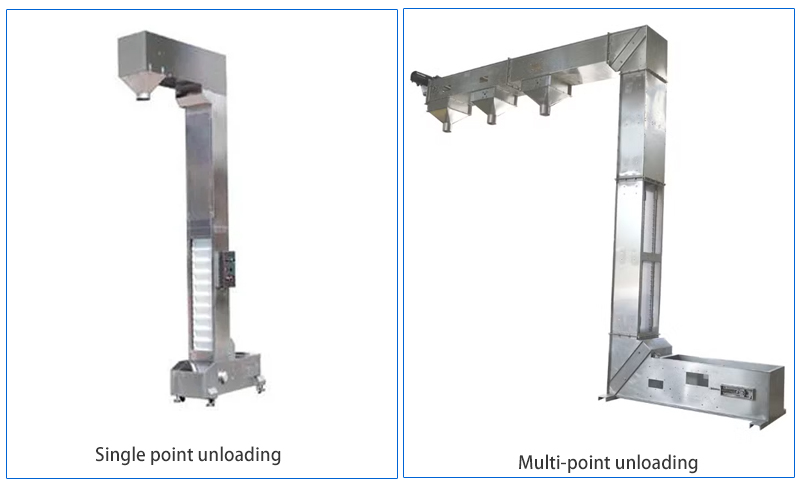

Types of Z type vertical elevator

Detailed explanation of Z type vertical elevator types

Z type vertical elevator is a common vertical conveying equipment, widely used in various industries. According to the different materials and unloading methods, Z type vertical elevators are mainly divided into the following types:

1. Material classification

Carbon steel Z type vertical elevator: suitable for conveying general materials, mainly used in mining, building materials, chemical industry and other industries, conveying materials with low hygiene requirements.

Stainless steel Z type vertical elevator: strong corrosion resistance, good hygiene performance, suitable for food, medicine and other industries with high hygiene requirements.

2. Unloading method classification

Single point unloading Z type vertical elevator: after the material is lifted to the highest point, it is unloaded at one time through a unloading port, which is suitable for occasions with short conveying distance and stable material flow.

Multi-point unloading Z type vertical elevator: multiple unloading points can be set according to needs, which is flexible and convenient, and suitable for occasions with long conveying distance and large material flow changes.

Advantage comparison between Z type vertical elevator and vertical screw conveyor

1. Low crushing rate: It adopts inflow feeding method, non-traditional excavation feeding method, and the material crushing rate of the whole process is low.

2. Flexible layout: There is a feed port at the lower end, and the discharge port is located at the upper end. The number of feed ports and discharge ports can be customized to meet the feeding needs of multiple silos in a row or multiple ports in production.

3. Sealing system: It adopts a closed casing design, negative pressure circulation loading and unloading, to avoid dust flying during the operation of the equipment and avoid pollution to the environment.

4. Wear-resistant/corrosion-resistant/food-grade materials: Carbon steel, 304, 316, spray-coated, PP, ABS plastics and other wear-resistant/corrosion-resistant/food-grade materials are provided.

Video

Technical specifications of Z type vertical elevator

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Application and demonstration of Z type vertical elevator

Z type vertical elevator is mostly used in the food processing industry. It vertically lifts food raw materials or food products. The inlet and outlet can be designed with multiple points, and can receive feed from multiple feeding equipment at the same time. The upper outlet can be arranged according to the actual layout. The number of equipment that needs high-altitude feeding is designed with 1-7 outlets, automatic continuous feeding, and production automation.

The vertical design of the Z type vertical elevator saves space and shortens material conveying time to the greatest extent during use. It is usually used with vibrating feeders, packaging machines, combination scales and other equipment to complete the vertical lifting work of 2-12m.

Z type vertical elevator structure and traction selection

The important structure of Z type vertical elevator includes hopper, traction system, power system, reducer, hydraulic system and electrical control system. In addition to complex electrical, hydraulic and power systems, the traction equipment of Z type vertical elevator can be selected according to the actual needs of users.

There are two types of hopper traction devices for Z type vertical elevators: belt traction and (plate) chain traction.

Belt traction is suitable for small vertical lifting height, small weight of materials to be lifted, no high temperature and no corrosion of materials, and it is characterized by stable operation, low noise and low configuration cost.

The chain traction device is suitable for conveying large vertical lifting heights, heavy lifting materials, and special properties of materials. The advantages of chain traction are stronger pressure bearing capacity and high temperature resistance, but compared with belt traction, the price is higher.

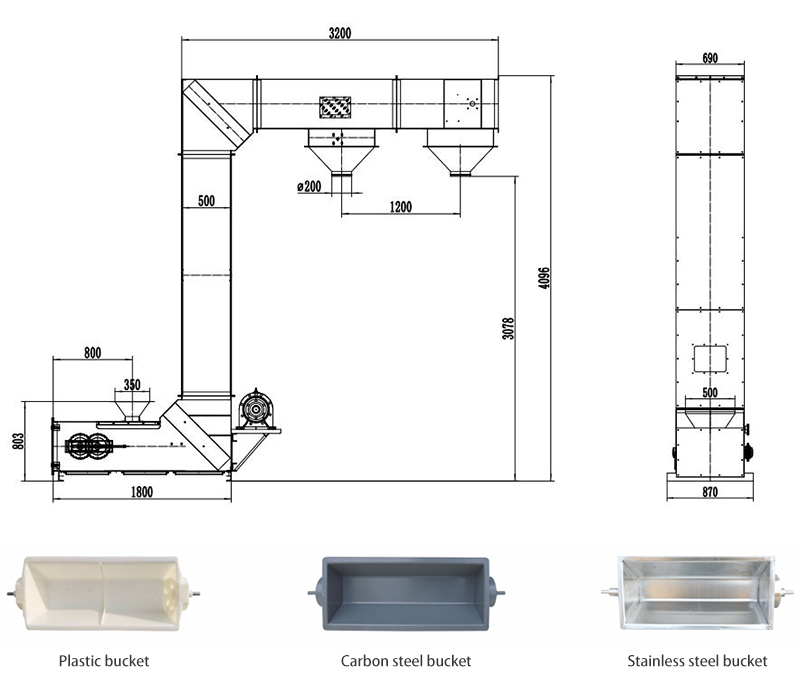

Optional configuration

The optional configurations of Z type vertical elevator include the following:

Chassis type: semi-enclosed chassis, dustproof chassis, airtight chassis, stainless steel chassis or carbon steel sprayed chassis.

Hopper material: stainless steel hopper, carbon steel hopper or food plastic hopper.

Drive mode: explosion-proof reducer or ordinary reducer.

Sprocket and chain: alloy steel sprocket, stainless steel sprocket, alloy steel chain or stainless steel chain.

Control system: manual start and stop, automatic start and stop or frequency conversion control can be configured.

Other configurations: explosion-proof of the whole machine, built-in forced ventilation system, automatic hopper cleaning system and automatic refueling system, etc.

Design Choices for Z type vertical elevator

Solutions by Industry