Belt Type Bucket Elevator

The rubber belt is used as a traction member for vertical conveying of various powder, fine and coarse particles

Material temperature: ≤60℃ (the temperature should not exceed 200℃ when using heat-resistant rubber belt)

Conveying capacity: 686m³/h

Lifting height: 100m

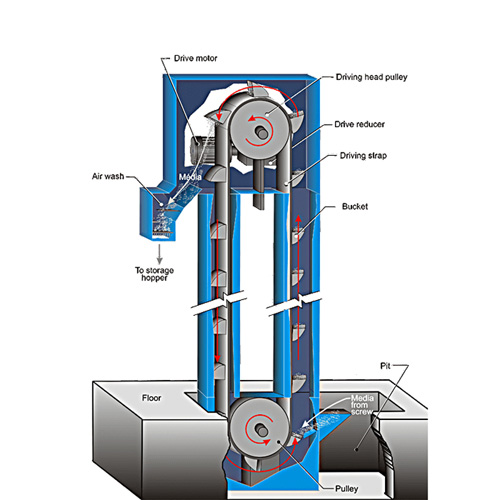

Introduction of Belt Type Bucket Elevator

The traction part of the belt type bucket elevator is a rubber belt. The hopper is fixed on the rubber belt at a certain interval. The rubber belt bypasses the rollers at the head and the bottom of the elevator respectively, forming a closed loop with an ascending loaded branch and a descending unloaded branch. System; when working, the driving device arranged at the head of the hoist transmits power to the rubber belt and the hopper through the head drum, the material enters the hopper from the feed port at the bottom of the hoist, and the hopper lifts the material to the discharge port of the head , Under the combined action of centrifugal force and gravity, the material in the hopper is discharged through the discharge port.

Application

Belt Type Bucket Elevator is mainly used for conveying granular, powdery and bulk materials within 150 degrees Celsius.

The Belt Type Bucket Elevator made of PVC is mostly used in the feed and grain industry.

The Rubber Belt Type Bucket Elevator is used in heavy duty industry and features abrasion, cutting and mineral oil resistance.

Food grade, abrasion resistant, vegetable oil and animal fat resistant belts for the food industry.

1. Traction: Belt

1) Material: generally use cotton core rubber tape, nylon core tape, steel cord core tape

2) Features: stable operation, low self-weight, low price, low noise, high working speed can be used, but low strength, punching fixed bucket makes the strength of the tape significantly reduced, commonly used in dry, low temperature, less oily It is not suitable to transport materials with high oil content, high temperature and humidity (such as cooked embryos).

3) The connection method of the belt:

a. Lap joint: simple, used a lot, but the winding at the joint is poor, pay attention to the direction of the joint should follow the direction of the tape running. Lap length > 2 hopper spacing;

b. Flat connection: poor joint winding

c. Corner joint: The corner joint belt has good flexibility, high strength, smooth joints, and smooth operation, which is suitable for some large-scale hoists.

| carcass material | fabric type |

single fabric thickness (mm/ply) |

single fabric strength (N/mm) |

Number of ply |

Cover rubber thickness (mm) |

belt width (mm) |

belt length (m) |

|

| upper | bottom | |||||||

| Cotton Canvas (CC) | CC-56 | 1.10 | 56 | 2-10 | 2.0-8.0 | 0-4.5 | 200-2500 | ≤400 |

| Polyester Cotton (TC) | TC-70 | 1.00 | 70 | 2-10 | 1.5-8.0 | 0-4.5 | 200-2500 | ≤400 |

| Nylon (NN) | NN100 | 0.75 | 100 | 2-10 | 1.5-8.0 | 0-4.5 | 200-2500 | ≤400 |

| NN150 | 0.80 | 150 | ||||||

| NN200 | 0.90 | 200 | 300-2500 | |||||

| NN250 | 1.15 | 250 | ||||||

| NN300 | 1.25 | 300 | 2-6 | |||||

| NN400 | 1.45 | 400 | 500-2500 | |||||

| NN500 | 1.55 | 500 | ||||||

| Polyester (EP) | EP100 | 0.80 | 100 | 2-10 | 1.5-8.0 | 0-4.5 | 200-2500 | ≤400 |

| EP125 | 0.85 | 120 | ||||||

| EP150 | 0.90 | 150 | ||||||

| EP200 | 1.05 | 200 | 300-2500 | |||||

| EP250 | 1.25 | 250 | ||||||

| EP300 | 1.35 | 300 | 2-6 | |||||

| EP350 | 1.50 | 350 | 400-25000 | |||||

| EP400 | 1.80 | 400 | ||||||

| EP500 | 2.00 | 500 | ||||||

Video

Belt Type Bucket Elevator conveying limestone

Belt Type Bucket Elevator Conveying Grain

Features and Benefits

1. With the belt as the traction part, no extra noise will be generated due to the collision of the traction part during the lifting process.

2. Because it is belt traction, there is no impact caused by chain traction due to its own structure, and the transmission is stable, so the linear speed can be greatly improved, the conveying material speed is large, and the carrying capacity is strong.

3. The large-capacity hopper is densely arranged, and there is almost no material returning and digging, so the power consumption is low.

4. Because of its small impact, the qualified belt bucket elevator has a long service life.

Structure of Belt Type Bucket Elevator

The belt type bucket elevator is mainly composed of the running part, the upper section with the driving drum, the lower section with the tensioning drum, the middle casing, the driving device, the backstop braking device, etc. The running device is mainly composed of the hopper and the Traction tape composition.

| Traction Method | Operation Control | Drive |

| cotton core rubber tape | Manual start and stop | Explosion-proof reducer |

| nylon core tape | Automatic start and stop | Ordinary reducer |

| steel cord core tape | Frequency Control | |

| Chassis | Hopper | Other Options |

| semi-closed | Stainless steel | The whole machine is explosion-proof |

| Totally closed | carbon steel | Built-in forced ventilation system |

| stainless steel | Plastic material | Hopper self-cleaning system |

| carbon steel spray paint | other/td> | Automatic refueling system |

| other | Multiple feed and discharge ports |

Technical parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

special design

Solutions by Industry

-

Belt Type Bucket Elevator Conveying Grain

-

Belt Type Bucket Elevator conveying limestone

-

White Silicone Belt Type Bucket Elevator Delivery Oatmeal