Bucket Elevator Conveyor

It is a device for vertical and continuous conveying of bulk materials. It consists of a series of buckets attached to a chain or belt that move in a cyclical pattern, creating an upward or downward flow of material.

Lifting material particles: 40-165mm

Lifting height: 40 meters

Lifting capacity: 15-800 m³/h

Bucket material: plastic, stainless steel or carbon steel

Applications; Capable of vertically conveying a wide variety of materials, including granular or powdered substances such as grains, seeds, fertilizers, cement, coal, sand, and minerals.

Introduction of Bucket Elevator Conveyor

A bucket elevator conveyor, sometimes simply referred to as a bucket elevator, is a mechanical device used to vertically lift or lower materials in a controlled manner. It consists of a series of buckets attached to a chain or belt that moves in a continuous loop, creating an upward or downward flow of materials. The buckets are designed to scoop up bulk materials from a lower level and carry them to a higher level.

Bucket elevator conveyors are commonly used in industries such as agriculture, mining, construction, and manufacturing, where the efficient vertical transportation of bulk materials is required. They can handle a wide range of materials, including grains, seeds, fertilizers, aggregates, chemicals, and more.

Types of Bucket Elevator Conveyor

The types of Bucket elevator conveyors can be divided into chain type, belt type and Z Type Bucket Elevator.

Belt Bucket Elevator Conveyor.: t is suitable for vertical conveying of powdery, granular, and small pieces of bulk materials with low abrasiveness and suction, such as grain, coal, cement, crushed ore, etc., with a maximum lifting height of 40m.

Chain bucket elevator conveyor: The forged chain is used as the transmission part, which has strong mechanical strength. It is mainly used for hoisting powder and small particles and small block materials. It is different from the belt bucket elevator. Its lifting capacity Larger and more efficient. It is often used for the lifting of materials with larger specific gravity.

Plate chain bucket elevator conveyor: adopts plate chain transmission, suitable for vertical transportation of medium, large and abrasive materials (such as limestone, cement clinker, gypsum, lump coal), and the material temperature is below 250 ℃.

Z Type Bucket Elevator:The shape of the machine is mostly "Z" or "C" type, which is characterized by the ability to design multiple discharge ports and feed ports, which are mostly used in light industrial applications such as food, agriculture, and snack processing.

Application

Bucket elevator conveyors find application in a wide range of industries where vertical transportation of bulk materials is required. Some common applications include:

Agriculture: Used in grain storage and handling facilities for transporting crops such as wheat, corn, rice and soybeans. They efficiently move grain from the ground to storage bins, silos or processing equipment.

Mining and Minerals: Used to transport various minerals and ores such as coal, iron ore, limestone, potash, phosphate and copper.

Construction and Construction Materials: For handling materials such as sand, gravel, cement, concrete and aggregates. They are used for the vertical transport of bulk materials in concrete mixing plants, asphalt plants and construction sites.

Chemicals and Fertilizers: For transporting granular or powdered chemicals and fertilizers. They facilitate the movement of materials such as urea, ammonium nitrate, phosphates and various compounds.

Food Processing: Suitable for conveying grains, grains, seeds and other food ingredients, they are used to lift and transport materials during grinding, mixing, drying and packaging.

Recycling and Waste Management: For processing materials such as shredded paper, plastic pellets, broken glass and other recyclable or waste materials. They assist in moving materials between different processing or storage areas.

Power Plant: Used in power generating facilities, especially coal-fired power plants. They transport coal from storage areas to boilers for combustion and dispose of fly ash and other by-products of power generation.

Application video

304 Stainless Steel Bucket Elevator Conveyor Conveying Bulk Seeds

Bucket Elevator Conveyor with multiple outlets vertically lifts nuts to multiple silos

Features and Benefits

1. Adopting inflow feeding, inductive discharging and large-capacity hopper intensive arrangement, there is almost no material returning and digging phenomenon when the material is lifted, so the ineffective power is low.

2. The hoist has less requirements on the types and characteristics of materials. It can convey powdery, granular, irregular or fragile and highly abrasive materials.

3. The important conveying equipment of packaging line and processing line can reach packaging or processing equipment up to 100 meters high, and the intensive design takes up less space.

4. The feeding of the elevator adopts the inflow type, no need to use a bucket to excavate the material, and there is little extrusion and collision between the materials. This machine is designed to ensure that the material is less scattered during feeding and unloading, which reduces mechanical wear.

Why choose Bucket Elevator Conveyor?

The design of the Bucket Elevator Conveyor means that it can gently and gently lift a wide variety of bulk materials vertically or at steep inclines.

Compared with inclined or vertical screw conveyors, which require the rotation of screw blades to generate friction, the biggest advantage of Bucket Elevator Conveyor is that when vertically conveying fragile and irregular materials, the use of hoppers will not cause damage to the surface of the materials, and convey dusty materials. Sealed design creates less dust and is more efficient when bulk powder is used. For example, some high-value and fragile products such as chocolate candies, potato chips, berries, nuts, coal, etc., or bulk powder materials such as powdered sugar, chocolate powder, stone powder, and cement.

The difficulty of vertical conveying of belt conveyors is very high, and most of them are open designs. Compared with the difficulties and pollution problems of belt conveyors when lifting or conveying powdery materials, Bucket Elevator Conveyor is a better choice.

In addition, Bucket Elevator Conveyor can have upper and lower horizontal sections and lifting sections (c-type and z-type design) at the same time in one machine. The horizontal section can be designed with multiple inlet and outlet ports according to your factory layout, directly to the silo.

Conveying equipment that can carry out large inclination angle of 30-90° or vertical conveying, suitable for irregular, block or particle conveying, simple structure and lowest cost, requires large placement space, and the conveying capacity decreases with the increase of the angle.

The screw equipment that can carry out vertical conveying is suitable for the lifting and conveying of materials with a short height below 8 meters. It is mostly used for processing powdery materials. It is required that the single feeding amount reaches the lifting standard or the material density is sufficient. use.

Optional design content

| Traction Method | Operation Control | Drive |

| plate chain | Manual start and stop | Explosion-proof reducer |

| ring chain | Automatic start and stop | Ordinary reducer |

| belt | Frequency Control | |

| Chassis | Hopper | Other Options |

| semi-closed | Stainless steel | The whole machine is explosion-proof |

| Totally closed | carbon steel | Built-in forced ventilation system |

| stainless steel | Plastic material | Hopper self-cleaning system |

| carbon steel spray paint | other | Automatic refueling system |

| other | Multiple feed and discharge ports |

Technical parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

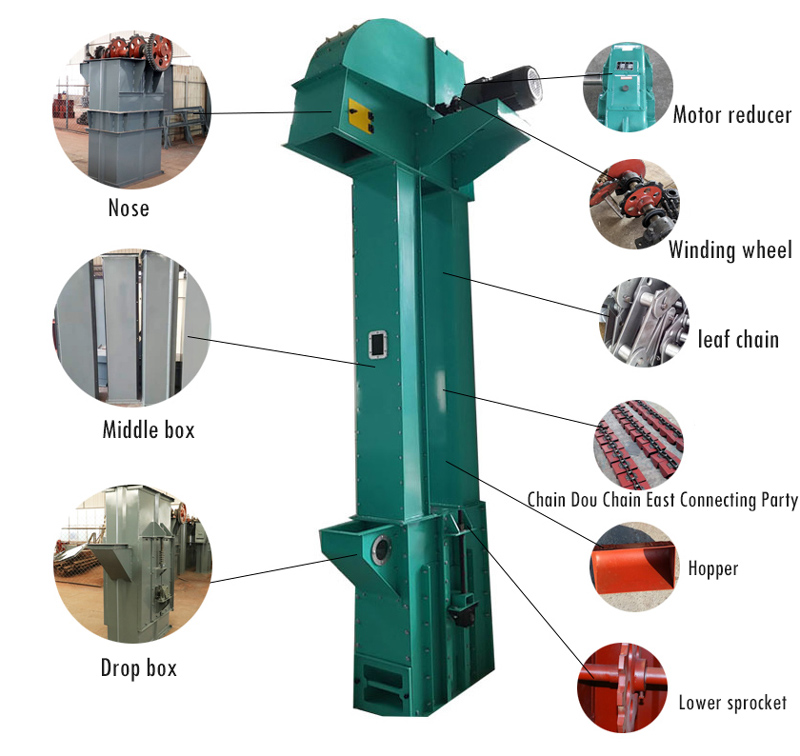

Structure of Bucket Elevator Conveyor

The components of Bucket elevator conveyor include belts, hoppers, traction members, drive rollers, tension rollers, and running parts.

Hopper: fixed on the tape (or traction chain), there are three types: deep hopper (suitable for loose materials), shallow hopper (material with greater viscosity), triangular hopper (material with large specific gravity and lumpy).

Housing: Built-in transmission and brakes.

Body: thin steel plate welded into a square shell.

Bottom: install tensioning device.

Grouped equipment

-

Bucket elevator conveyor with trommel screen

-

Bucket elevator conveyor with storage tank

-

Bucket elevator conveyor with screw feeder

-

Bucket elevator conveyor with vibrating feeder

-

Bucket elevator conveyor with belt conveyor

-

Bucket elevator conveyor with cement tank

Solutions by Industry

-

Confectionery factory delivering fondant

-

Multiple Bucket Elevator Conveyors are used in parallel with feed bins

-

Carbon Steel Fully Sealed Bucket Elevator Conveyor

-

Conveying clinker pellets

-

Food factory cooperates with packaging machine to convey

-

Feed mill lifting feed pellets

-

Multi-point discharge to lift lime