Chain Bucket Elevator

Utilizes a continuous chain with an attached bucket to transport bulk materials and is built to withstand heavy loads and rough operating conditions.

Type: chain/plate chain

Lifting capacity: 800m³/h

Lifting height: ≤ meters

Application: Suitable for conveying powdery, granular, small-block, low-abrasive materials with a bulk density of less than 1.5t/m³ and easy to take out. Such as: coal, cement, gravel, sand, fertilizer, etc.

Introduction of Chain Bucket Elevator

Chain bucket elevator is a type of vertical conveyor system that utilizes a continuous chain with attached buckets to transport bulk materials. These elevators are widely used in various industries to move materials vertically between different levels.

Chain bucket elevators are commonly used in industries such as agriculture, mining, cement, and food processing for vertically conveying materials such as grains, seeds, fertilizers, ores, and powders. They offer advantages such as high capacity, efficient material handling, and the ability to transport materials over long vertical distances.

Types of Chain Bucket Elevator

Chain bucket elevators can be classified into different types based on various factors such as design, construction, and application. Here are some common types of chain bucket elevators:

1.Round Link Chain Bucket Elevator: Buckets are attached to a round link chain that moves in a continuous loop. This design offers durability and reliability when handling heavy and abrasive materials.

2.Central Chain Bucket Elevator: Features a central chain with buckets mounted along the length of the chain. This design provides a simple and efficient method of moving bulk materials vertically and is suitable for a variety of material handling in a variety of industries, including agriculture, mining, and industrial applications.

3.Single Chain Bucket Elevator: Consists of a single chain with buckets mounted at regular intervals. This type of elevator is a simpler design and is suitable for handling materials with medium capacity requirements.

4.Double Chain Bucket Elevator: Two parallel chains with buckets mounted between them for vertical transport of materials, this design increases capacity and stability compared to single chain elevators. Ideal for heavy-duty applications that require higher capacity and greater stability, such as large industrial plants, mining operations or high-capacity material handling facilities.

Working Principle of Chain Bucket Elevator

Material Loading:At the bottom of the elevator, the buckets are loaded with the material to be transported. The material can be fed into the buckets either manually or through a feeding mechanism.

Vertical Transport:The chain moves in a continuous loop, carrying the buckets along the defined path. As the chain moves, the buckets sequentially pick up the material from the loading point at the bottom.

Lifting:The loaded buckets are lifted vertically as they move up along the elevator's casing.

Discharge:Upon reaching the head section of the elevator, the buckets approach the discharge point, which is typically located at the top of the elevator.Depending on the type of chain bucket elevator, the material can be discharged through centrifugal force, continuous discharge, or positive discharge mechanisms.

Video

Features and Benefits

1. The inflow feeding system is adopted, which can make the material lift almost without the phenomenon of returning and digging during the mechanical operation process, reducing the ineffective power.

2. The metal chain has a stronger bearing capacity and a breaking force of 2,500 kN, which is suitable for the lifting and conveying of large particles and heavy materials up to 40 meters.

3. Reasonable design principles and processing methods ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours.

4. Good sealing performance and less environmental pollution.

5. The material is conveyed in the vertical direction, so it occupies a small area and can effectively save space.

Technical parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

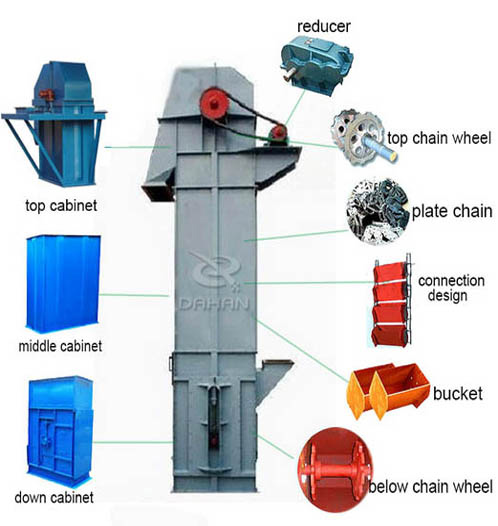

Structure of Chain Bucket Elevator

Buckets: The buckets are attached to the conveying element (chain or belt) and are designed to scoop up, transport, and discharge materials at the top of the elevator.

Chain: The chain runs around sprockets or pulleys at the top and bottom of the elevator, providing the driving force to move the buckets.

Drive Unit: The drive unit, which can be an electric motor or other power source, provides the necessary power to move the chain or belt and lift the materials.

Head Section: The head section houses the drive unit and sprockets/pulleys. It is where the loaded buckets are discharged at the top of the elevator.

Boot Section: The boot section is located at the bottom of the elevator and is responsible for receiving and feeding the materials into the buckets.

Tensioning Device: A tensioning device is used to maintain the proper tension in the chain or belt to ensure smooth operation and prevent slippage.

Bucket Elevator Chain

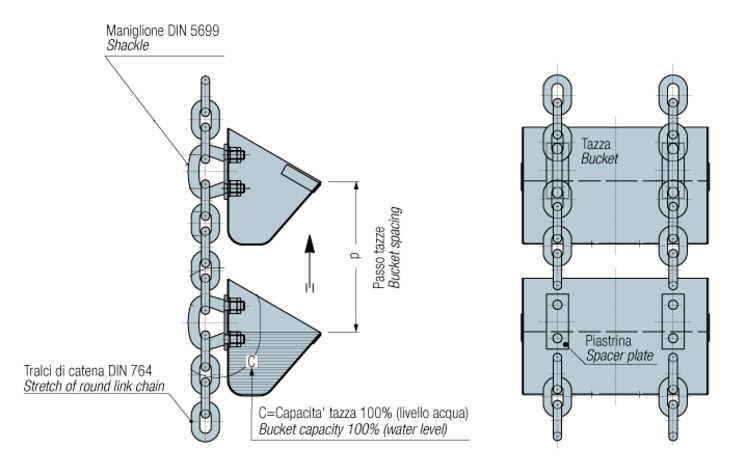

1. Round chain

Round chains are generally divided into TH160 bucket elevator chain (Φ14), TH250 bucket elevator chain (Φ18), TH315 bucket elevator chain (Φ20), TH400 bucket elevator chain (Φ20), TH500 bucket elevator chain (Φ20), etc., which are commonly used in the market. After proper heat treatment, the round chain has high tensile strength and wear resistance and long service life.

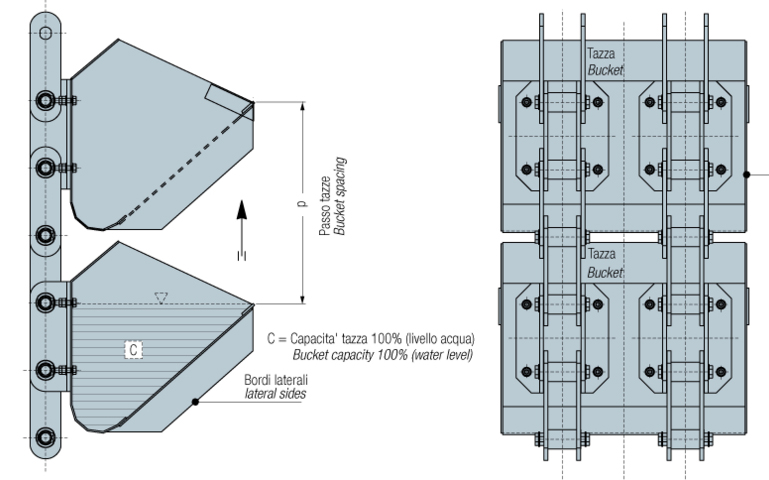

2. Plate chain

NE plate chain is generally divided into NE15 bucket elevator chain, NE30 bucket elevator chain, NE50 bucket elevator chain, NE100 bucket elevator chain, NE150 bucket elevator chain, NE200 bucket elevator chain, NE300 bucket elevator chain, NE400 bucket elevator chain and other standards. The hoist plate chain is easy to repair in the later stage. If one section is severely worn, it can be replaced directly.

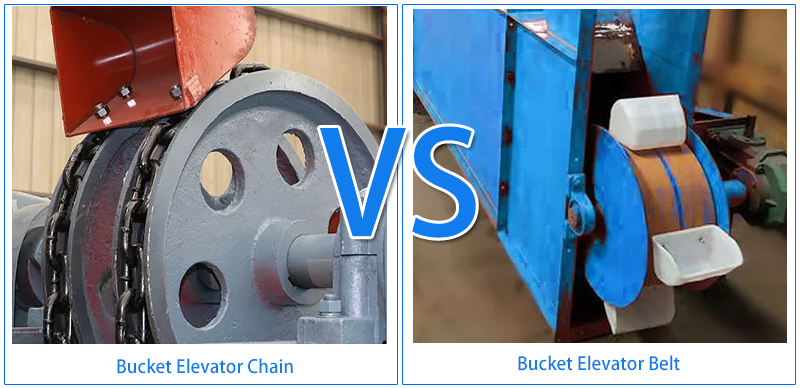

What is the difference between bucket elevator chain and belt?

The primary difference between chain bucket elevators and belt bucket elevators lies in their traction components and suitability for various materials and conditions.

| Difference | Bucket Elevator Chain | Bucket Elevator Belt |

| Material | Typically made of steel for durability and strength | Often made of rubber or synthetic materials for flexibility |

| Attachment | Buckets are directly attached to the chain links | Buckets are attached to the belt using bolts or other means |

| Durability | Chains are more durable and suitable for heavy-duty loads | Belts can be prone to wear and may need more frequent replacements under heavy loads |

| Maintenance | Chains may require lubrication and periodic inspection | Belts may need tension adjustment and periodic replacements |

| Noise Level | Chains can produce more noise during operation | Belts tend to run quieter |

| Speed | Chains can handle higher speeds | Belts are limited by their material and construction |

| Operation | Provides a positive drive for the buckets | Offers smooth and continuous operation |

| Applications | Common in heavy industries like mining and cement plants | Suitable for industries with lighter loads and gentle handling |

Application

Chain bucket elevator is a plate-chain/loop-chain, gravity-induced unloading lifting equipment. NE series plate chain bucket elevator is suitable for vertical conveying of powdery, granular, small block abrasive or non-abrasive materials, such as raw meal, cement, coal, limestone, dry clay, clinker, etc.

-

Chain Bucket Elevator with trommel screen

-

Chain Bucket Elevator with storage tank

-

Chain Bucket Elevator with screw feeder

-

Chain Bucket Elevator with vibrating feeder

-

Chain Bucket Elevator with belt conveyor

Solutions by Industry

-

Chain Bucket Elevator applied in grain base

-

Chain Bucket Elevator applied in mining

-

Chain Bucket Elevator used in concrete production

-

All stainless steel Chain Bucket Elevator for food or medicine