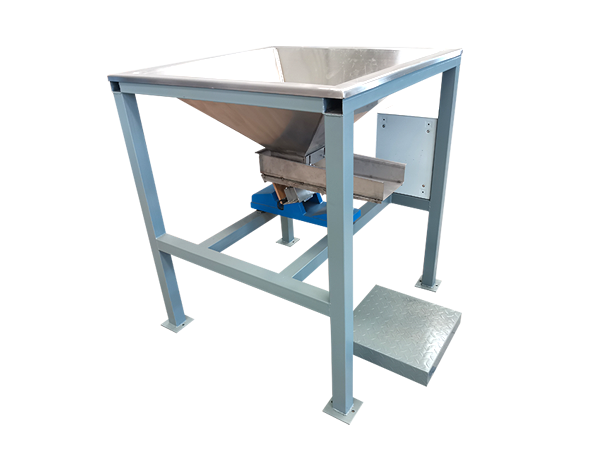

Electromagnetic Vibrating Feeder

Electromagnetic vibration is used to move materials along the trough, thus achieving precise batching and uniform flow.

Power Type: Electric

Vibration frequency: 3000 times/min

Max Feeding Size: 50-100mm

Capacity: 25-35t/h

Application: Commonly used in industries such as mining, metallurgy, coal, building materials, chemicals, etc., which require controlled and consistent material flow.

What is an electromagnetic vibrating feeder?

Electromagnetic vibrating feeder is a device used to precisely control the flow rate of granular materials. It operates on the principle of electromagnetic vibration, where an alternating current passes through a coil, creating a magnetic field that attracts and releases a magnetic plate. This periodic attraction and release generates a linear vibration, causing the material on the feeder tray to move forward in a controlled manner.

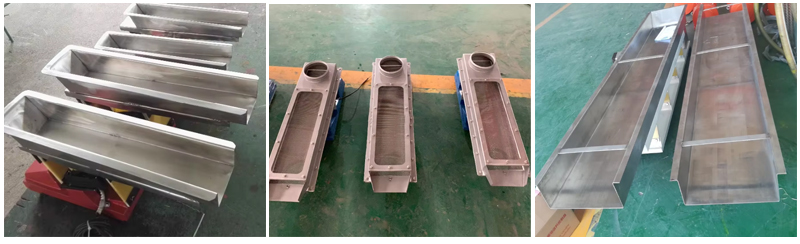

Our feeders are available in ten different models with capacities ranging from 25 to 100 tons per hour. They are available in SS 304/316L or mild steel. The chutes vibrate at 3000 times per minute and are able to handle a wide range of materials from the finest powders to large coarse particles.

Types of electromagnetic vibrating feeder

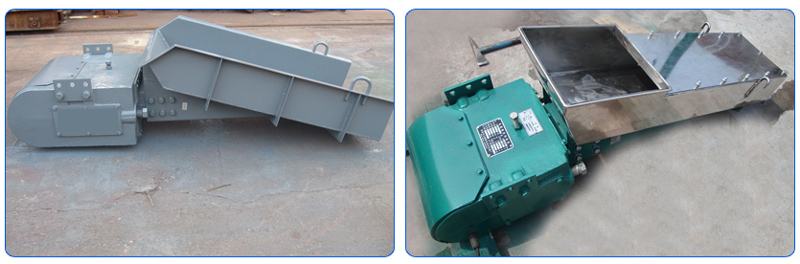

1.Different materials

Carbon steel: Q235 carbon steel trough is used, which is suitable for customers with low hygiene requirements, and the price is cheap.

Stainless steel: It is made of SUS304 stainless steel trough, which is resistant to corrosion, high temperature, not easy to rust, and can avoid the pollution of raw materials.

2.Different structure

Open type: It is a common structure. Suitable for material feeding without special requirements.

Enclosed type: Enclosed electromagnetic vibrating feeder adopts closed body design, which can prevent dust pollution. It is suitable for feeding materials with fragile particles, large dust and easy volatilization.

3. Different installation method

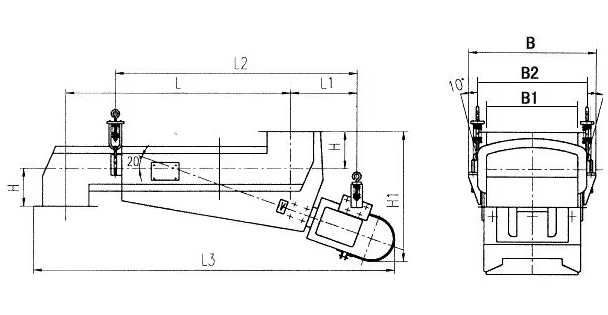

Seat type: Under normal conditions, it can be installed with a downward tilt of 10°. For materials with high viscosity or high water content or fine powder, it can be installed with a downward tilt of 15°.

Hanging type: Hanging type installation, the body performs periodic linear reciprocating motion along the groove direction to achieve uniform and quantitative feeding. After installation, the feeder should have a 20mm swimming gap, and the horizontal direction should be horizontal. The suspension device adopts flexible connection .

4. Different trough:

Light groove type: suitable for feeding light materials with small specific gravity.

Flat groove type: suitable for uniform feeding of thin material layers.

Wide groove type: The double vibrating head design is adopted, which widens the width of the groove body, increases the particle size of the receiving material, and at the same time increases the feeding amount, which can send the entire receiving device (such as a belt conveyor or a crusher) to the whole receiving device. Cross-section uniform cloth. Mainly used for coal preparation, and can also be used to feed the screening equipment.

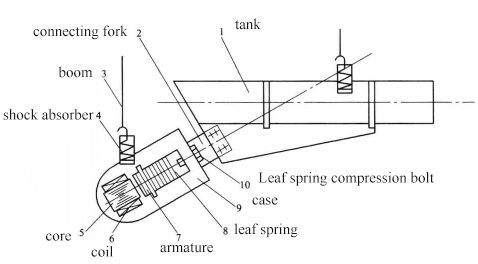

How do electromagnetic vibratory feeder works?

An electromagnetic vibratory feeder works based on the principle of electromagnetic vibration. Here is a simplified explanation of how it operates:

Electromagnetic Coil: The feeder consists of a coil that is energized with an alternating electric current, creating a magnetic field around it.

Armature: Connected to the coil is an armature, often in the form of a spring-mounted iron core. When the coil is energized, it generates a magnetic field that attracts the armature towards it.

Vibration: As the alternating current in the coil changes direction, the polarity of the magnetic field also changes rapidly. This causes the armature to move back and forth due to the attraction and repulsion forces between the coil and the armature.

Material Flow: The movement of the armature results in vibrations that are transferred to the feeder trough or channel. These vibrations cause the material in the trough to move along the trough in a controlled manner.

Video

Features and Benefits

1. The amplitude is 1.5-3mm, and the vibration frequency is high, up to 3000 times/min.

2. The material flow can be changed and opened and closed instantaneously, so the feeding amount has high accuracy.

3. The electromagnetic vibrating feeder controller adopts the thyristor half-wave rectifier circuit, so during use, the feeding amount can be adjusted steplessly by adjusting the opening angle of the thyristor, and the concentration of the production process can be realized. control and automatic control.

4. The material in the feeding trough is continuously thrown up during the feeding process, and jumps forward according to the trajectory of the parabola, so the wear of the feeding trough is small and the equipment replacement cost is low.

5. Due to the use of the resonance principle of mechanical vibration, the double-mass body works in a low critical near-resonance state, so it consumes less power.

Technical parameters

| Types of | Model | Productivity(t/h) | Feed particle sizemm | Double amplitudemm | Voltage(V) | Current(A) | Power(Kw) | Matching control box | ||

| level | -10 degrees | Working current | Indicates current | |||||||

| Basic | GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | ||||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | ||||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | XKZ-20G3 | |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | ||||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | |||

| GZ10 | 750 | 1050 | 500 | 39.4*2 | 32*2 | 4*2 | XKZS-200G3 | |||

| GZ11 | 1000 | 1400 | 500 | 47.6*2 | 38.6*2 | 5.5*2 | ||||

| Up mode | GZ3S | 25 | 35 | 75 | 1.75 | 220 | 4.58 | 3.8 | 0.2 | XKZ-5G2 |

| GZ4S | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

| GZ7S | 250 | 350 | 250 | 24.6 | 0 | 3 | XKZ-100G3 | |||

| GZ8S | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| Closed | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2F | 8 | 11.2 | 40 | 3 | 2.3 | 0.15 | ||||

| GZ3F | 20 | 28 | 60 | 4.58 | 3.8 | 0.2 | ||||

| GZ4F | 40 | 56 | 60 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | ||||

| GZ6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

| light groove | GZ5Q | 100 | 140 | 200 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 |

| GZ6Q | 150 | 210 | 250 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | ||

| GZ7Q | 250 | 350 | 300 | 24.6 | 20 | 3 | XKZ-100G3 | |||

| GZ8Q | 400 | 560 | 350 | 39.4 | 32 | 4 | XKZ-100G3 | |||

| Flat groove | GZ5P | 50 | 70 | 100 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 |

| GZ7P | 75 | 105 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |||

| GZ7P | 158 | 175 | 24.6 | 20 | 3 | XKZ-100G3 | ||||

| Wide groove | GZ5K1 | 240 | 100 | 1.5 | 220 | 12.7*2 | 10.6*2 | 0.65*2 | XKZ-20G2 | |

| GZ5K2 | 240 | |||||||||

| GZ5K3 | 270 | |||||||||

| GZ5K4 | 300 | |||||||||

| Round tube | GZ1G | 2 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 | |

| GZ2G | 4 | 50 | 3.0 | 2.3 | 0.15 | XKZ-5G2 | ||||

| GZ3G | 10 | 60 | 4.58 | 3.8 | 0.2 | XKZ-5G2 | ||||

| GZ4G | 20 | 70 | 8.4 | 7 | 0.45 | XKZ-20G2 | ||||

| GZ5G | 40 | 80 | 12.7 | 10.6 | 0.65 | XKZ-20G2 | ||||

| Extra large | GZ11-T | 100 materials are coal with a specific gravity of 0.85 | 300 | 1.5 | 380 | 47.6*2 | 38.6*2 | 5.5*2 | SZK.00 | |

Structure of electromagnetic vibrating feeder

The key components of an electromagnetic vibrating feeder typically include:

Electromagnetic Coil: Generates the magnetic field that drives the vibrations.

Armature: Connected to the coil, it moves back and forth in response to the electromagnetic forces, causing the feeder to vibrate.

Feeder Trough: The trough or channel through which the materials flow as a result of the vibrations.

Controller: Regulates the frequency and intensity of the vibrations to control the material flow rate.

Customized electromagnetic vibrating feeder

Electromagnetic vibrating feeders can be customized according to different needs. Common customization types include:

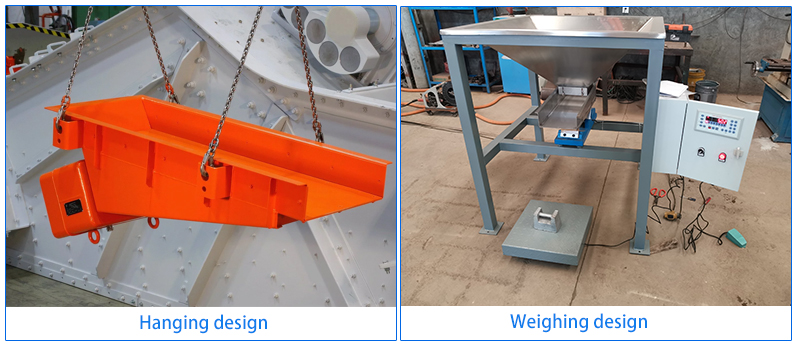

Hanging design: Hanging electromagnetic vibrating feeders are usually designed to be suspended on brackets or hooks, suitable for occasions where hanging installation is required, such as limited space or places that require flexible movement.

Weighing design: It combines the functions of electromagnetic vibrating feeder and weighing system, and is used to accurately measure and control the supply of materials. It is widely used in occasions where accurate measurement of material supply is required, such as food processing, chemical production, pharmaceutical industry and other fields.

Customization for special requirements

High temperature materials: high temperature resistant materials and cooling measures can be used.

Easy to clog materials: measures such as lengthening the feed trough and increasing the vibration frequency can be adopted.

Large particle materials: measures such as thickening the trough plate and increasing the vibration intensity can be adopted.

Application

IElectromagnetic vibrating feeder has a wide range of application scenarios in industrial production, mainly including but not limited to the following fields:

Mining and mining industry: used to supply granular materials such as ore and coal from storage bins or hoppers to production lines such as crushers and screening equipment on demand.

Building materials: used to accurately supply granular raw materials such as sand, stone, cement to production lines such as concrete mixing stations and crushing equipment.

Chemical industry: used to accurately supply powdered or granular chemical raw materials such as granules and powders to production equipment such as reactors and mixing equipment.

Food processing: often used to supply granular or powdered food raw materials such as grains and powdered sugar to food processing production lines to ensure the continuity and stability of the production process.

Pharmaceutical industry: can be used to supply granular or powdered materials such as drug powder and capsule raw materials to mixing, tableting and other equipment in drug production lines.

Packaging industry: used for raw material supply on automatic packaging lines to ensure the automation and efficiency of the packaging process.

Solutions by Industry

-

Mines and Mining Companies

Mines and mining companies often use electromagnetic vibrating feeders to feed raw materials such as ore and coal to production lines such as crushers and screening equipment to improve production efficiency and reduce manual operations.

-

Building Material Manufacturer

Building material manufacturers may use electromagnetic vibrating feeders to automatically feed raw materials such as sand, stone, cement, etc. to concrete mixing plants or other production equipment to meet construction needs.

-

Food Processing Companies

Food processing companies often use electromagnetic vibrating feeders to accurately feed food raw materials such as grains and powdered sugar to food processing production lines to ensure the continuity of the production process and food quality.