food grade bucket elevator

Flexible vertical conveyor machine specially designed for lifting and handling packages in the food industry.

Machine shell material: 304 or 316L food grade stainless steel

Hopper material: food grade ABS

Hopper volume: 1.8L, 4.0L and 6.0L (can be customized)

Lifting height: 2-12m

Conveying speed: 2-5m³/h

Conveying capacity: 3-10m³/h

Inlet and outlet: single or multiple

product description

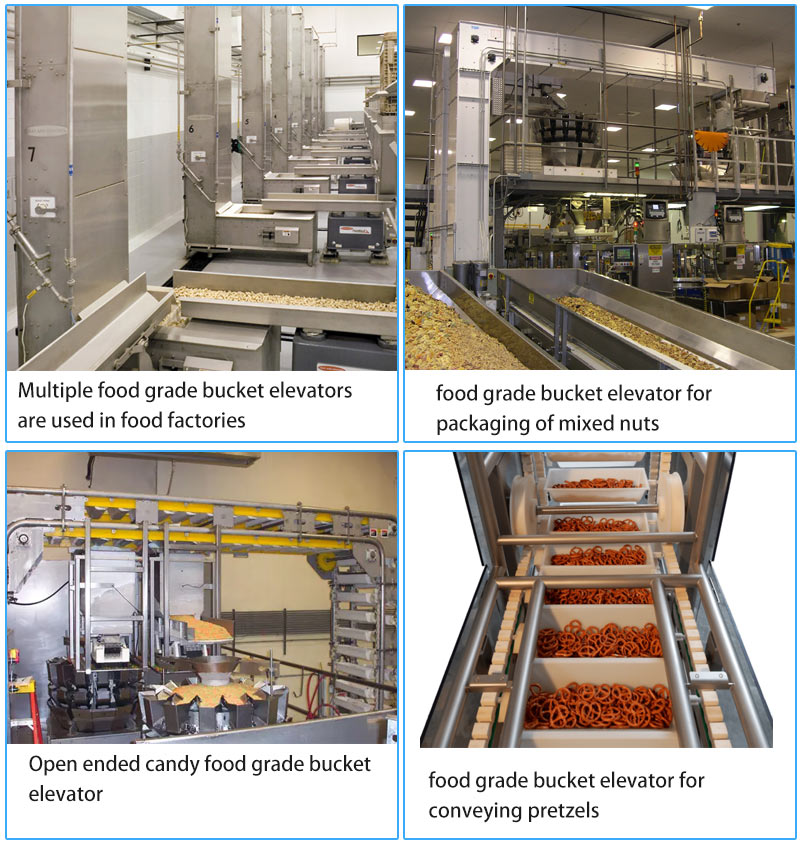

Food grade bucket elevator is a kind of lifting equipment specially used in the food industry for vertical transportation of food raw materials or finished products. It adopts materials and designs that meet the hygiene standards of the food industry to ensure food safety and hygiene. The bucket of the food-grade bucket elevator is made of food-grade plastic or stainless steel, with a smooth surface and a no-dead-angle design to facilitate cleaning and prevent food residues.

In addition, food grade bucket elevators also take into account the special requirements of food, such as not damaging fragile foods and avoiding food cross-contamination. It is widely used in food processing, packaging and logistics to ensure food quality and safety.

Types of food grade bucket elevator

Food grade bucket elevators are mainly divided into the following two types:

1. Ordinary vertical food grade bucket elevator: This type of elevator adopts an upright vertical structure and is used to vertically lift food raw materials or finished products to different heights. It usually has adjustable lifting speed and capacity, and is suitable for the vertical transportation needs of various food industries, with a vertical height of up to more than 10 meters.

2. Food grade Z type bucket elevator: This type of elevator adopts a Z-shaped direction, which allows the bucket to move more complexly in the horizontal and vertical directions. Handle gently to avoid damage or breakage, suitable for lifting fragile foods.

Applications

Food grade bucket elevators are widely used in the food industry, including the following aspects:

1. Food processing: Food grade bucket elevators are used to vertically lift food raw materials from the ground or storage equipment to processing equipment, such as mixers, crushers, screening machines, etc.

2. Packaging industry: In the food packaging process, food-grade bucket elevators are used to lift packaging materials, such as bagged food, canned food, or bottled food, from the ground to the packaging machinery to achieve automated packaging processes. It ensures efficient packaging processes and food safety.

3. Condiments and ingredients industry: Food-grade bucket elevators can be used to vertically lift condiments, spices, ingredients and other food ingredients. They can accurately transport different ingredients to mixers or batching machines to ensure the accuracy of product formulas. sex and consistency.

4. Food storage and distribution: Food grade bucket elevators can be used to vertically lift food raw materials or finished products from storage warehouses or silos to downstream distribution systems, such as conveyor belts or other transportation equipment, for packaging, loading or Delivery.

5. Grain processing and storage: It can be used to vertically lift grain, feed or other grain products. They can lift raw materials from the ground or storage equipment to mills, dryers, grain storage silos and other equipment for grain processing or storage.

Video

Product advantages

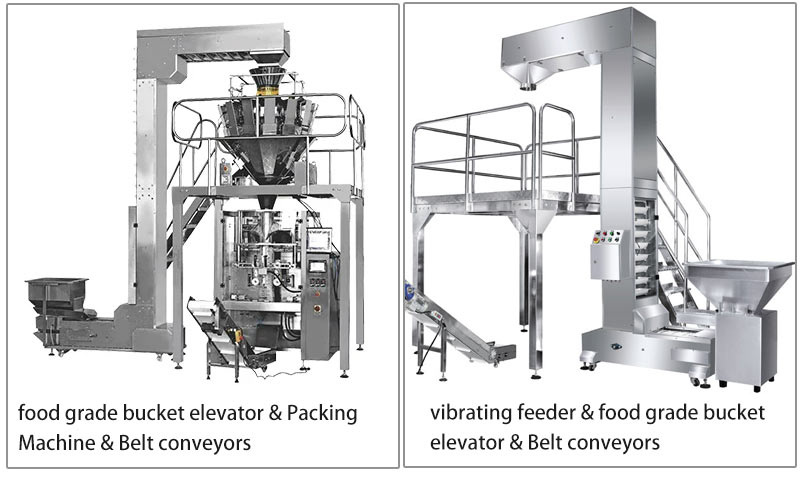

1. SS304 or 316L stainless steel material, the hopper is made of food-grade ABS material, which is safe and pollution-free and meets food standards

2. Gentle conveying to avoid damage caused by mutual extrusion of materials

3. It can cooperate with the vibrating feeder to realize automatic and uniform feeding, and the pipeline program conveys

4. The hoisting equipment with the smallest footprint under the same conveying capacity can flexibly adapt to the layout of the factory

5. Able to match the number of original feeding equipment and packaging equipment in the factory, and design multiple inlet and outlet ports

Product Specifications

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need6 |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

product details

Available options

Food grade bucket elevator is a common lifting equipment in the food industry. It is made of stainless steel and complies with food safety and hygiene standards. Here are some options and features to choose from:

1. Stainless steel bucket material: The bucket of a food-grade stainless steel bucket elevator is usually made of 316L stainless steel or other stainless steel materials that meet food-grade standards. These materials have good corrosion resistance, antibacterial properties and high temperature resistance, and are suitable for the promotion of various food raw materials and finished products.

2. Hygienic design: The food-grade stainless steel bucket elevator has a hygienic design, including a smooth surface, rounded corner design and a structure without dead corners. This design reduces the possibility of food residues and bacterial growth, facilitates cleaning and disinfection, and ensures food safety and hygiene.

3. Adjustable lifting speed and capacity: Food-grade stainless steel bucket elevators usually have adjustable lifting speed and capacity to adapt to the needs of different food production lines. It can be adjusted according to the actual situation to ensure the efficiency and stability of the lifting process.

4. Dust-proof and anti-pollution measures: In order to prevent food cross-contamination and the entry of external pollutants, food-grade stainless steel bucket elevators usually take dust-proof and anti-pollution measures. For example, the equipment can be equipped with sealing covers, dust-proof mats, dust-proof doors, etc. to maintain the purity of food.

Industry Solutions