grain bucket elevator

Grain bucket elevator is a piece of equipment used to vertically transport grain and other free-flowing bulk materials. It is a common sight in farms, grain storage facilities, and food processing plants.

Material particle size: 25-70mm

Lifting capacity: 5.4-30 tons/hour

Lifting height: ≤20 meters

Application: Transports bulk materials such as grains, seeds or granular produce from one level to another.

product description

Grain bucket elevator is a specialized conveyor system used in the agricultural industry to vertically transport grains such as wheat, corn, rice, barley, and more. This equipment plays a crucial role in efficiently moving grains from one location to another within a processing facility, storage silo, or grain handling operation.

Grain is loaded into the elevator from below, usually through the feed opening or hopper. When the chain or conveyor belt moves, the bucket moves with it, lifting the grain vertically upward. When the bucket-shaped baffle reaches the top, The bucket tips over, allowing the grain to be discharged to its destination, such as a storage facility, processing equipment, or other conveyor system.

Grain bucket elevator is an essential piece of equipment in the agricultural industry for the efficient and gentle handling of grains. By investing in a reliable and well-designed grain bucket elevator, grain handling operations can improve efficiency, minimize grain damage, and ensure the smooth vertical transport of grains throughout the processing and storage process.

Applications

Grain bucket elevator is a common equipment used for vertical conveying of granular materials (such as grains, cereals, etc.), and is commonly used in the following applications:

Grain processing plants: used to transport raw materials or finished products from one processing stage to another, such as grain from cleaning, screening to grinding and other processes.

Grain storage: used to transport grain from the ground to the height of the storage facility for storage and distribution.

Feed production: Grain elevators are often used to transport granular materials such as grains and feed raw materials for mixing, processing and packaging.

Grain processing workshops: used to transport raw materials from the ground to different processing equipment, such as mills, mixers, etc.

Agricultural fields: can be used to transport materials such as grains and seeds to help improve production efficiency.

Video

Product advantages

1.Vertical Conveying: Bucket elevators can move grain vertically, allowing for efficient utilization of space and the ability to transfer grain to different levels within a facility.

2.High Capacity: Bucket elevators can handle large volumes of grain, making them suitable for commercial grain handling operations.

3.Gentle Handling: The design of the buckets and the controlled flow of grain minimize damage or breakage, ensuring the integrity of the grain during the lifting process.

4.Versatility: Grain bucket elevators can handle a wide range of grain types, including wheat, corn, soybeans, barley, and more.

5.Automation: Bucket elevators can be integrated into automated systems, allowing for efficient and continuous grain handling operations.

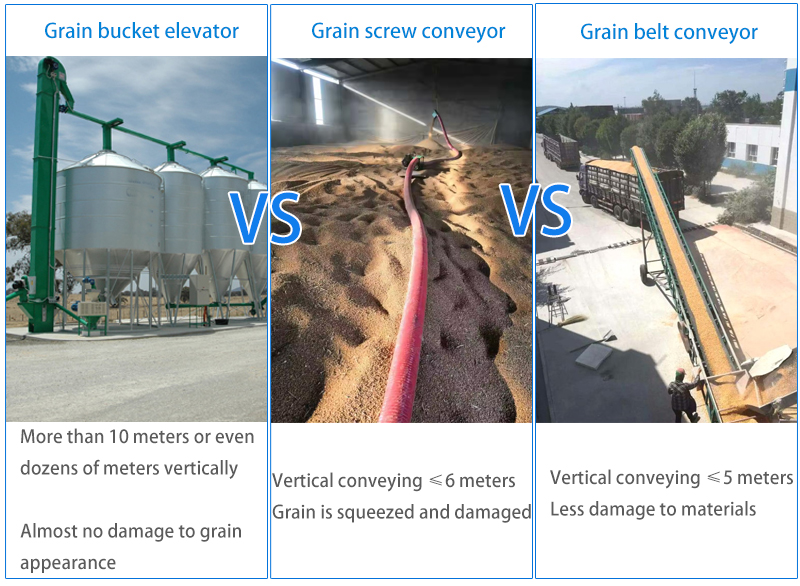

Difference between grain bucket elevator and other grain conveyors

Compared with other grain conveyors, the grain bucket elevator has the following differences:

| Comparison Items | Grain bucket elevator | Other grain conveyors (such as screw conveyors, belt conveyors) |

| Application | Mainly used for vertical transportation, suitable for lifting granular and powdery materials, such as grains, feed, powder, etc. | Can be used for horizontal, inclined or vertical conveying, with a wider range of adaptability, and can convey a variety of materials, including block, granular, powder, etc. |

| Conveying height | It is good at vertical transportation, with a large conveying height, which can reach tens of meters or even higher. | The conveying height is relatively low, generally not exceeding 6 meters, and is usually used for short-distance conveying. |

| Grain damage rate | Very low, because the material is turned in the bucket instead of being pushed by friction like traditional conveying methods, the impact and extrusion of the granular material is reduced, thereby reducing the breakage rate. | High, especially for screw conveyors, the grain is subject to greater friction between the spiral blades and the tube wall, especially when the conveying speed is fast, the friction will increase, which will cause grain damage. |

| Site restrictions | It has high space requirements and requires a certain height, which is suitable for vertical space utilization. | Relatively low space requirements, can be flexibly arranged according to the site. |

| Cost | The initial investment is relatively high, but the maintenance cost is low. | The initial investment is relatively low, but the maintenance cost may be high, especially for belt conveyors. |

Product Specifications

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

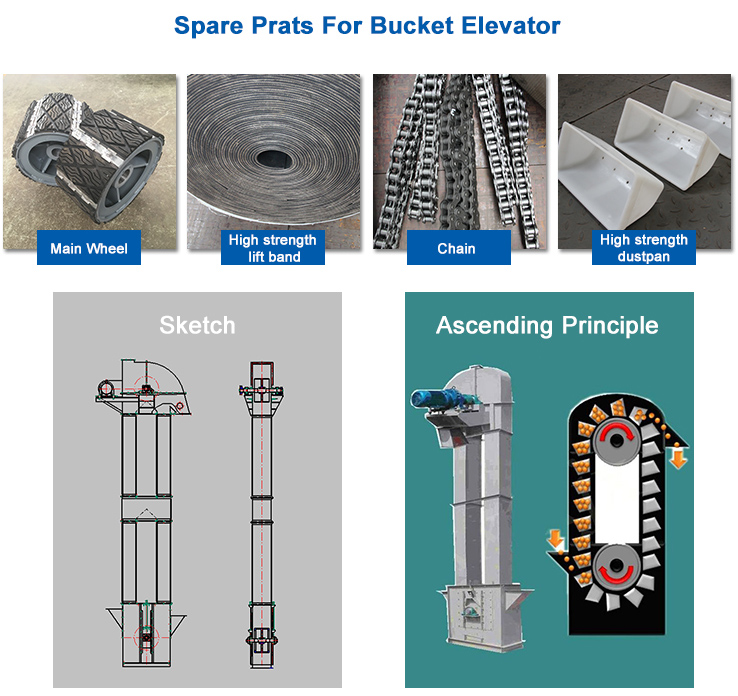

product structure

The components of the grain bucket elevator include belts, hoppers, traction parts, drive pulleys, tension pulleys and running components.

Hopper: fixed on the belt (or traction chain), there are three types: deep bucket (suitable for loose materials), shallow bucket (materials with high viscosity), triangular bucket (materials with heavy specificity and block shape).

Housing: Built-in derailleur and brake.

Fuselage: thin steel plates welded into a square shell.

Bottom: Install tensioner.

How to choose grain bucket elevator?

When conveying grains of different particle sizes, it is very important to choose the right equipment model and configuration. Here are some selection suggestions:

1. Small grains: such as wheat and corn, with a particle size range of 1-5 mm, choose a standard bucket or a deep bucket, which is suitable for handling smaller particles, and choose the appropriate tonnage according to production needs.

2. Medium grains: such as rice and beans, with a particle size range of 5-10 mm, it is recommended to choose a deep bucket design, which can accommodate more materials, reduce the funnel effect, and be equipped with dust prevention devices to keep the working environment clean.

3. Large grains: such as corn kernels and feed pellets, with a particle size range of 10-20 mm, can be deep buckets or special buckets to ensure the effective conveying of large particle materials.

4. Coarse particles or mixtures: such as feed and grain mixtures, with a particle size range of more than 20 mm, it is recommended to choose a special deep bucket to ensure the stability of conveying, and choose a model with high conveying capacity to meet the needs of mass production. In addition, consider using wear-resistant materials to extend the service life of the equipment.

Note: The smaller the particles, the easier it is to generate dust, and the higher the sealing requirements of the equipment. The larger the particles, the higher the requirements for the hopper strength.

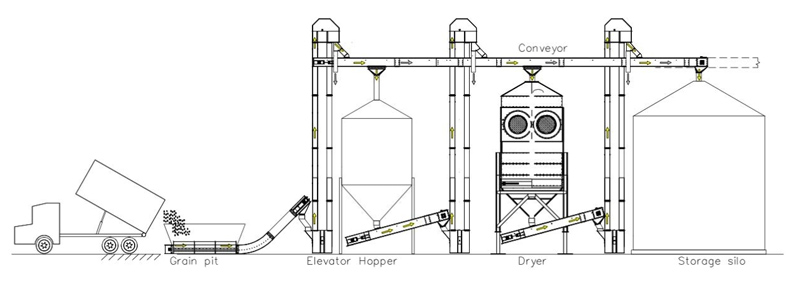

Systematic solution

When used with silos and other processing equipment, grain bucket elevators can form an efficient material conveying and handling system. Here are some suggestions for solutions:

1. Bucket elevators and silos: Bucket elevators convey grain from the bottom to the top of the silo for easy storage and subsequent processing. Ensure that the outlet of the bucket elevator matches the inlet of the silo to avoid material overflow

2. Bucket elevators and cleaning equipment: Install a cleaning screen in front of the inlet of the bucket elevator to remove impurities before lifting. Combined with airflow cleaning equipment, the purity of the grain can be further improved.

3. Bucket elevators and crushers: Convey the lifted grain to the crusher for processing, design a reasonable conveying path, and ensure smooth connection between the elevator and the crusher.

4. Bucket elevators and mixers: Convey the lifted grain to the mixer for uniform mixing. Adjust the working time and speed of the mixer according to the characteristics of different grains.

5. Bucket elevator and packaging machine: The lifted grain is transported to the packaging machine for final packaging. A weighing system is set between the bucket elevator and the packaging machine to ensure the accuracy of each packaging.

Solutions by Industry

-

Transporting Wheat

Wheat needs to be transported from ground storage warehouses to above the crushing equipment. They chose a grain bucket elevator with high vertical conveying capacity. The elevator can efficiently lift wheat vertically from the ground to the feed port of the crushing equipment, ensuring continuous operation and high productivity of the production line.

-

Transporting Corn

Corn needs to be transported from ground storage warehouses to high-rise drying equipment. To meet their needs, they adopted a high-speed, large-capacity grain bucket elevator. This elevator can transport corn vertically to the drying equipment at high speed and stability, improving production efficiency and corn quality.

-

Transporting Seeds

Different types of seeds need to be transported from ground warehouses to above the seed sorting and packaging equipment. To meet their requirements for seed protection and quality, they selected a grain bucket elevator. The elevator is designed with a special bucket and sealing device to ensure that the seeds are not damaged during transportation and reduce dust generation.