Vertical Bucket Elevator

Vertical bucket elevator is a type of material handling equipment used for vertical transportation of bulk materials or products. It consists of a series of buckets attached to a belt or chain that moves in a continuous loop, allowing for efficient and reliable vertical conveying.

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-40 tons/hour

Lifting height: ≤15 meters

Lifting speed: 1.4-2 m/s

Applications: Commonly used in various industries including agriculture, mining, manufacturing and food processing to handle materials such as grains, seeds, fertilizers, aggregates, chemicals and more.

Introduction of Vertical Bucket Elevator

Vertical bucket elevator, also known as a continuous bucket elevator or a high-capacity bucket elevator, is a type of material handling equipment used for vertical transportation of bulk materials or products. It consists of a series of buckets attached to a belt or chain that moves in a continuous loop, allowing for efficient and reliable vertical conveying.

Vertical bucket elevators are used in various industries for transporting materials such as grains, seeds, fertilizers, aggregates, chemicals, and more. They are especially useful for lifting materials to heights where traditional conveyors may not be suitable.

Types of Vertical Bucket Elevator

| Chain Elevator | TD Belt Elevator |

|

|

| Capacity: 16 ~ 185m3/h | Capacity: 5~142 m3/h |

| Chain( Dia*Dis): 14x50, 22x86mm | Belt width: 200 ~700 mm |

| Powder max size: 20~660mm | Powder max size: 25~55 mm |

| Customization is acceptable | Customization is acceptable |

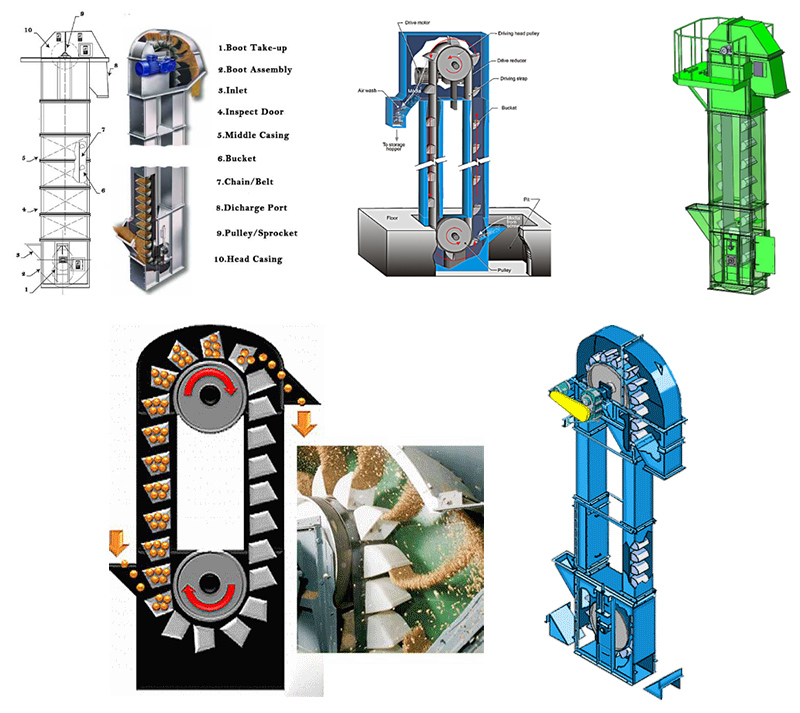

Working Principle of Vertical Bucket Elevator

Here's a breakdown of how a vertical bucket elevator works:

Endless loop: The core of the system is a looped chain or belt that continuously rotates around sprockets or pulleys at the top and bottom of the elevator.

Attached buckets: Secured to this loop at specific intervals are buckets designed to hold and transport the bulk material.

Loading and discharge: As the loop rotates, the buckets travel down the vertical leg (where they are filled with material) and then up the vertical leg (where they discharge the material).

Features and Benefits

1. Adopt inflow feeding, inductive discharging and large-capacity hopper intensive arrangement. There is almost no material returning and digging phenomenon when the material is lifted.

2. It is used for vertical conveying of various forms of bulk materials, which can cope with the conveying of high temperature, irregular and fragile products, with a small footprint.

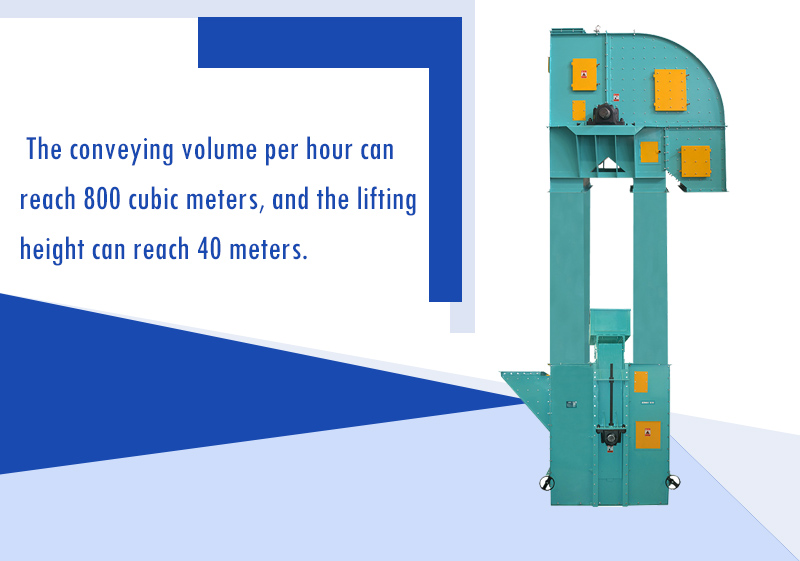

3. The conveying volume per hour can reach 800 cubic meters, and the lifting height can reach 40 meters.

4. The operation reliability is good, and the trouble-free time exceeds 20,000 hours.

5. Long service life, the feeding of the elevator adopts the inflow type, no need to use a bucket to excavate the material, and there is little extrusion and collision between the materials. The machine is designed to ensure that the material is rarely scattered during feeding and unloading fall, reducing mechanical wear.

6. The casing is tightly sealed to ensure that there is no dust pollution in the process of lifting materials.

Application video

Vertical Bucket Elevator for sand loading

Vertical Bucket Elevator with multiple outlets vertically lifts nuts to multiple silos

Difference Between Vertical Bucket Elevator and Vertical Screw Conveyor

| Difference | Vertical Bucket Elevator | Vertical Screw Conveyor |

|

|

|

| Application | Can handle a variety of materials including dry bulk materials, powders, granules, and even semi-fluid materials. They are suitable for materials of various particle sizes, moisture contents and flow characteristics. | Designed primarily for handling dry, free-flowing bulk materials such as grains, seeds, fertilizers and aggregates. They are not suitable for handling sticky or sticky materials, as this may cause the bucket to clog or the material flow to become inconsistent. |

| Capacity | Screw conveyors generally have lower capacities compared to bucket elevators. They are suitable for applications with medium to low material throughput requirements. | Designed for high-volume material handling. They can efficiently handle large volumes of material, making them suitable for applications with high material throughput requirements. |

| Space requirements | Usually have a larger footprint. Due to the length of screw conveyors, they require longer horizontal space. | The design is more compact and requires less horizontal space. They are suitable for installation in facilities with limited space. |

| Lift height | ≤15 meters | ≤2.5 meters |

Technical parameters

| Model | Large feed sizemm | Hopper | lift heightm | Lifting capacity (m3/h) | Hoist weight | ||

| Bucket distancemm | WidthMM | CapacityL | |||||

| TB250 | 90 | 200 | 250 | 3 | 5-40 | 25 | Check and determine according to the specific vertical bucket elevator ordering general drawing |

| TB315 | 100 | 200 | 315 | 6 | 46 | ||

| TB400 | 110 | 250 | 400 | 12 | 75 | ||

| TB500 | 130 | 320 | 500 | 25 | 95 | ||

| TB630 | 150 | 400 | 630 | 50 | 148 | ||

| Note: The maximum conveying capacity in the table is calculated according to the filling factor ψ-0.8, which is for reference only. | |||||||

Why Choose Vertical Bucket Elevator

| name | Vertical Bucket Elevator | vertical screw conveyor | Large inclination belt conveyor |

| Delivery angle | 90° vertical lift | 90°vertical conveying | 30-90° conveying |

| Delivery capacity | powerful | stronger | Normal conveying below 50°, weakened conveying capacity above 50° |

| Conveying distance | 40 meters | 8 meters | Generally 10 meters |

| Applicable situation | All kinds of materials that need long-distance lifting | Short-distance lifting of powder or small granular materials | Generally not used for powdery materials |

| features | Large lifting capacity and long distance, no material leakage | Short lift, good seal, possible clogging | Not recommended for 90° vertical delivery |

| Floor area | smaller | Small | larger |

Optional Design Showcase

| Material Description |

Max Particle Size (IN) |

Bulk Density (Lbs/Ft3) |

Suggested Type | Abrasive Rating | Corrosive Rating | Flow Rating |

| Alfalfa Meal | -0.125 | 17 | Continuous | II | I | III |

| Alum, lumpy | 0.5 | 50-60 | Centrifugal, Continuous | I | I | II |

| Barley | -0.125 | 37-48 | Centrifugal | I | I | I |

| Beans, Castor, whole | -0.5 | 36 | Centrifugal, Continuous | I | I | I |

| Beans, Navy | -0.5 | 48 | Centrifugal, Continuous | I | I | I |

| Bentonite | -100M | 50-60 | Centrifugal | II | I | II |

| Bentonite, crude | 0.5 | 34-40 | Centrifugal | II | I | III |

| Cocoa, beans | -0.5 | 30-45 | Centrifugal, Continuous | I | I | II |

| Cocoa, nibs | -0.5 | 35 | Centrifugal, Continuous | I | I | II |

| Coffee, roasted bean | -0.5 | 22-26 | Centrifugal, Continuous | I | I | I |

| Coffee, green bean | -0.5 | 32-45 | Centrifugal, Continuous | I | I | II |

| Coke, calcined | 0.5 | 35-45 | Centrifugal | III | I | II |

| Coke, loose | 0.5 | 23-32 | Centrifugal | III | I | III |

| Copra | 0.5 | 22-33 | Centrifugal, Continuous | I | I | II |

| Copra, cake | 0.5 | 25-30 | Centrifugal, Continuous | I | I | II |

| Flaxseed | -0.125 | 43-45 | Centrifugal | I | I | I |

| Malt, wet or green | -0.5 | 60-65 | Centrifugal | I | I | III |

| Marble, crushed | -0.5 | 80-95 | Continuous | III | I | II |

| Muriate of Potash | -0.125 | 77 | Centrifugal, Continuous | III | III | II |

| Mustard Seed | -0.125 | 45 | Centrifugal | I | I | I |

| Oats | -0.5 | 25-35 | Centrifugal | I | I | I |

| Oats, rolled | -0.5 | 19-24 | Centrifugal | I | I | II |

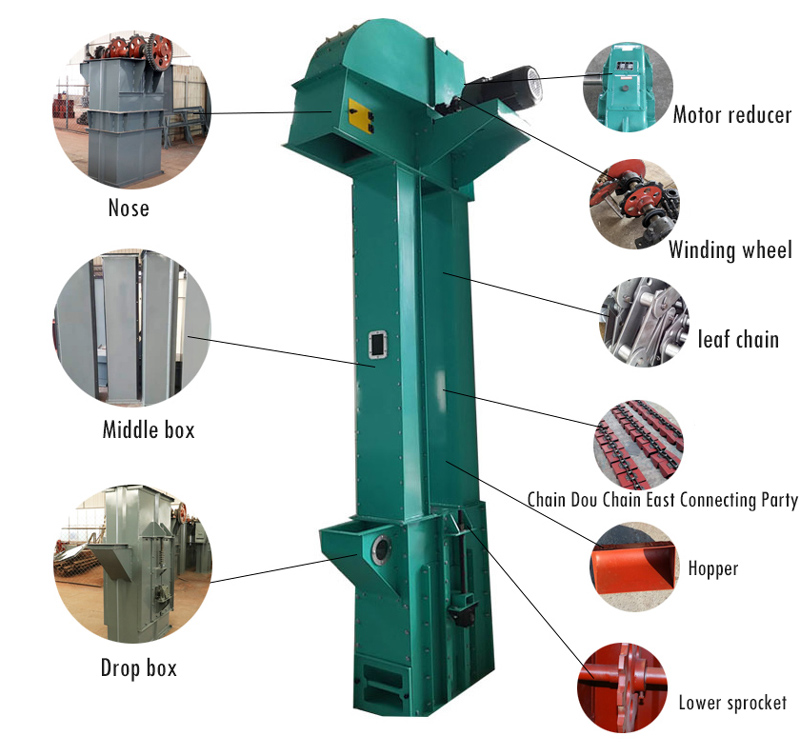

Structure of Vertical Bucket Elevator

The vertical bucket elevator consists of a casing, a traction part (conveyor chain), a hopper, a driving wheel (head wheel), a redirection wheel (tail wheel), a tensioning device, a guiding device, a feeding port (feeding port) and a discharging port Port (discharge port) and other parts.

Housing: Housing: Built-in transmission and brakes.

Traction: It is a plate sleeve roller chain. The single chain is fixed on the rear wall of the hopper. The double chain is connected to both sides of the hopper. When the width of the hopper is 160~250mm, the single chain is used. chain.

Hopper: Cylindrical hopper: The deep hopper and the mouth of the hopper are inclined at 65°, and the depth is large. It is used for drying, good fluidity and well-scattered granular materials.

Shallow hopper: The mouth is inclined at 45° and the depth is small, for wet and fluid granular materials.

1) Deep hopper: generally used to dry materials with good fluidity.

2) Triangular hopper: The material is generally directional self-flow discharge.

3) Sharp-angled bucket: its side wall extends outside the bottom plate and becomes a rib. When discharging, the material can be unloaded along the groove formed by the ribs and the bottom plate of a bucket, which is suitable for viscous and heavy block materials transport.

Sprockets: Sprockets are used to mesh with precisely pitched blocks on link links or cables, and are solid or spoked gears that mesh with roller chains to transmit motion.

Optional

| Traction Method | Operation Control | Drive |

| plate chain | Manual start and stop | Explosion-proof reducer |

| ring chain | Automatic start and stop | Ordinary reducer |

| belt | Frequency Control | |

| Chassis | Hopper | Other Options |

| semi-closed | Stainless steel | The whole machine is explosion-proof |

| Totally closed | carbon steel | Built-in forced ventilation system |

| stainless steel | Plastic material | Hopper self-cleaning system |

| carbon steel spray paint | other | Automatic refueling system |

| Totally closed | carbon steel | Built-in forced ventilation system |

| other | Multiple feed and discharge ports |

Application

Vertical bucket elevators find applications in various industries and sectors where there is a need for vertical transportation of bulk materials. Some common applications of vertical bucket elevators include:

1.Grain handling: Vertical bucket elevators are extensively used in the agriculture industry for handling grains, such as wheat, corn, rice, barley, and soybeans. They are utilized in grain storage facilities, flour mills, feed mills, and other grain processing plants for lifting grains to different levels, such as silos, bins, or processing equipment.

2.Mining and aggregates: In the mining and aggregates industry, vertical bucket elevators are employed for handling materials such as coal, limestone, sand, gravel, and other bulk minerals. They facilitate the vertical transfer of mined materials from underground or surface mining operations to processing plants, stockpiles, or loading points.

3.Food processing: Vertical bucket elevators are widely used in the food processing industry for handling various food products, including cereals, nuts, seeds, snacks, confectionery, and frozen foods. They transport these materials between different processing stages, such as mixing, cooking, cooling, drying, packaging, and storage.

4.Construction and aggregates: Vertical bucket elevators are also employed in the construction industry for handling materials like cement, sand, gravel, and aggregates. They transport these materials to different levels in concrete plants, asphalt plants, and construction sites.

5.Recycling and waste management: Vertical bucket elevators can be used in recycling facilities and waste management plants for lifting and transferring recyclable materials, such as plastics, glass, paper, and metals, to different processing or sorting stations.

Solutions by Industry

-

Vertical Bucket Elevator lifts powder vertically

Vertical height: 8 meters

-

Vertical Bucket Elevator with silo

Vertical height: 10 meters

-

Vertical bucket elevator conveying rice and grain

Vertical height: 15meters