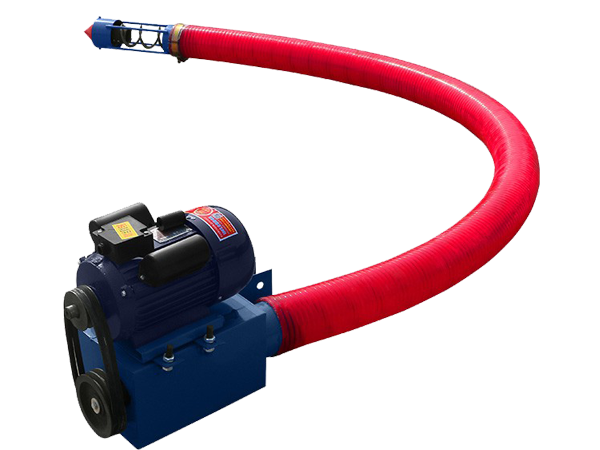

Flexible Feed Auger

Commonly used in various applications in the feed industry, such as conveying feed ingredients, mixing feed ingredients and distributing feed to different locations, suitable for loading and unloading feed ingredients from trucks, silos or other storage containers.

Pipe diameter: 100-160mm

Conveying distance: 3m-30m

Vertical conveying height: 3m-4m

Conveying capacity: 5-20t/h

Voltage: 220-380v or design

Application: Cattle feed, chicken feed, pig feed, duck feed, fish feed

Introduction of Flexible Feed Auger

Flexible feed auger is a type of equipment used in the agricultural industry to transport feed and other materials from one location to another. It consists of a flexible tube with a spiral-shaped metal core that is driven by an electric motor. The tube is usually made of a durable, lightweight material, such as PVC or polyurethane, to allow for flexibility and easy installation.

The flexible feed auger is commonly used in livestock feeding systems, where it is used to transport feed from a storage bin to a feeding trough or other feeding equipment. It can also be used for other applications, such as conveying grain or other materials in processing facilities.

Application

Conveying Feed Ingredients: Used to move feed ingredients from one point to another within a feed production facility. For example, they can be used to move grain, pellets and other feed ingredients from storage tanks to mixers or other processing equipment.

Mixed feed ingredients: Can be used to mix feed ingredients together. They can be designed with special mixing sections to ensure that ingredients are thoroughly mixed before being conveyed to the next processing step.

Distributing Feed: Used to distribute feed to various locations within the facility. For example, they can be used to deliver feed to different animal pens or feeders.

Loading and unloading: Can be used to load and unload feed ingredients from trucks, silos or other storage containers.

Video

Features and Benefits

1. Easy installation: light weight and easy installation, which makes it a popular choice for farmers and agricultural workers.

2. Flexible design: The flexible tube enables it to easily go around obstacles, such as walls or other equipment, which makes it ideal for use in tight spaces.

3. Gentle handling The ability to handle feed and other materials gently, which helps minimize damage to the material and maintain its quality.

4. Low maintenance cost: the design has low maintenance cost, few moving parts, simple and reliable design.

5. Cost-effective: Often less expensive than other types of feeding systems, making them a popular choice for farmers and agribusinesses.

Technical parameters

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

Special design

1. Portable: The suction hose is a flexible tube used to suck the grain into the machine. It is usually made of a durable material such as PVC or polyurethane. , with small size, high power, easy to move, easy to carry and so on.

2. Vehicle-mounted: It can be directly stuck on the heightened wall of the truck box. It can be bent and moved, and is easy to carry. It is suitable for loading, unloading, storage, and storage of various feeds.

3. Hand-held: It consists of a hand-held tube with a suction mechanism that sucks the grain into the tube and transports it to the desired location. Manual flexible feed augers are relatively inexpensive compared to larger grain handling equipment, making them a cost-effective option for smaller operations.

Solutions by Industry

-

A pig farm needed a solution to transport a mixture of grain, soybean meal and other supplements from storage bins to feeders. The flexible screw design of the conveyor also handles feed and supplements gently to prevent breakage and dust generation, and can meet the requirements of high-volume feed production on the farm,

-

A large cattle farm needed a solution to transport a mixture of grain, supplements and additives from storage bins to feeders. They chose a flexible feed auger because of its ability to handle ingredients of varying particle sizes and densities without separation or clogging. The cattle farm is satisfied with the conveyor's performance and efficiency in reducing waste and labor costs.

-

A chicken processing plant needed a solution to transfer the mixture of ground meat, bones and other by-products from the deboning system to the rendering system. They chose a flexible screw conveyor because of its ability to handle the high viscosity and abrasive nature of the by-product without clogging or abrasion. The conveyor's flexible screw design can also be easily maintained and customized to fit its specific layout and space constraints.