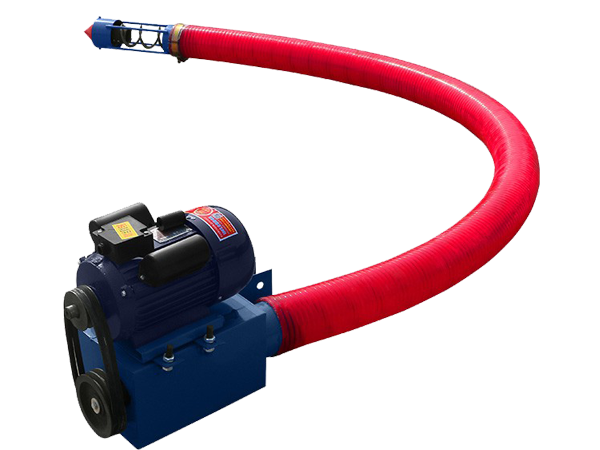

Flexible Grain Lifter

It is an agricultural equipment used for grain conveying, suction, loading, stacking and storage, suitable for conveying grains such as wheat, paddy, corn, rice, beans, etc.

Pipe diameter: 100mm/120mm/160mm

Conveying length: 3m-12m

Vertical height: 3m-4m

Conveying capacity: 4-20 tons/hour

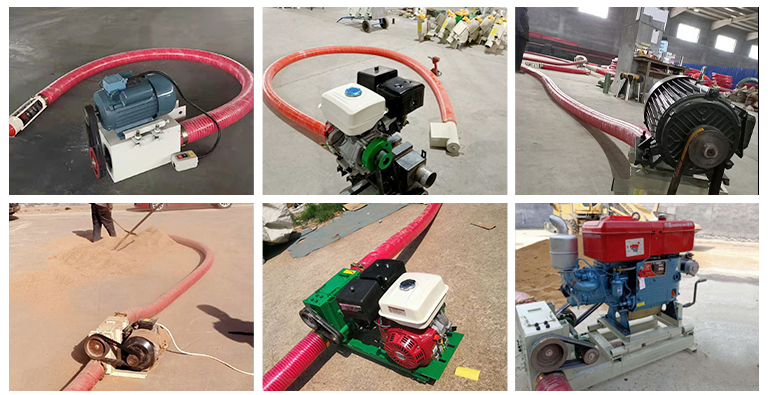

Drive: single motor/three phase/Gasoline engine/diesel engine

Introduction of Flexible Grain Lifter

Flexible grain lifter, also known as a flexible auger grain conveyor or a flexible screw grain conveyor, is a type of conveyor system that is used to move grain from one point to another. The conveyor consists of a flexible spiral screw enclosed in a flexible casing, which is designed to fit into tight spaces and around corners.

Flexible grain lifters are commonly used in the agricultural industry for handling grain, feed, and other granular materials. They are often used in grain storage facilities, feed mills, and on farms for tasks such as filling and emptying grain bins, loading and unloading trucks, and transferring grain between storage facilities.

Application

Flexible grain lifters are widely used in the agricultural field. They are commonly used to handle grain, feed and other granular materials in a variety of tasks, including:

Filling and Emptying Grain Tanks: Commonly used to fill and empty grain tanks on farms and grain storage facilities. The conveyor's flexible construction allows it to be installed in tight spaces and around corners, making it ideal for grain silo applications.

Loading and unloading trucks: trucks used to load and unload grain and feed. The flexibility of the conveyor allows it to enter the truck bed and move the material to the desired location.

Transferring grain between storage facilities: Used to transfer grain between different storage facilities, such as from a storage silo to a feed mill and vice versa. The flexibility and versatility of this conveyor makes it ideal for this application.

Mixing and Mixing Feeds: Can be used to mix and blend different types of feeds and grains. Conveyors can be customized to meet the specific needs of an application, such as adding liquid additives or mixing different types of feed.

Filling and emptying feeders: Commonly used to fill and empty livestock feeders. The flexibility of the conveyor allows it to enter the feeder and move the feed to the desired location.

Viedo

Features and Benefits

Versatility: Can handle a variety of grain types and sizes. Its flexible structure allows it to fit into tight spaces and corners, making it ideal for a variety of applications.

Cost-Effective: Often a more cost-effective option compared to other types of conveyors. It has a lower initial cost and requires less maintenance, which saves costs in the long run.

Low Maintenance: There are few moving parts, which means it requires very little maintenance. Other types of conveyors, such as belt or chain conveyors, may require more maintenance to keep them running smoothly.

Easy to use: easy to use and can be operated by one person. Its simple design makes it easy to install and adjust to meet the specific needs of the application.

Efficient: Grain can be moved quickly and easily. Its flexibility allows it to handle a variety of material handling tasks, such as filling and emptying grain tanks, loading and unloading trucks, and transferring grain between storage facilities.

How does the flexible grain lifter compare to other types of conveyor systems?

Compared to other types of conveyor systems, the flexible grain lifter has several advantages and disadvantages. Here are some key comparisons:

Versatility: The flexible grain lifter is a versatile conveyor system that can be customized to fit the specific needs of different applications. It can handle a wide range of grain types and sizes, and its flexible structure allows it to fit into tight spaces and around corners. Other types of conveyors, such as belt conveyors or chain conveyors, may have limitations in terms of material handling and space requirements.

Capacity: The capacity of the flexible grain lifter is typically lower than other types of conveyors. While it is suitable for small to medium-sized grain handling operations, larger operations may require a higher capacity system, such as a belt conveyor or screw conveyor.

Maintenance: The flexible grain lifter has few moving parts, which means it requires minimal maintenance. Other types of conveyors, such as belt conveyors or chain conveyors, may require more maintenance to keep them running smoothly.

Cost: The flexible grain lifter is generally a more cost-effective option compared to other types of conveyors. It has a lower initial cost and requires less maintenance, which can result in long-term cost savings. Other types of conveyors may have higher initial costs and ongoing maintenance expenses.

| Compared | Flexible Grain Lifter | Belt Conveyor | Screw Conveyor |

| Design | Grain is lifted and transported using flexible pipes with discs attached to the ends. | Use a continuous endless belt to move grain from one point to another. | The grain is moved forward using the helical screw rotating inside the tube. |

| Capacity | Typically used in low volume applications. | Belt conveyors are ideal for long-distance and high-volume applications. | Suitable for medium and small capacity applications. |

| Maintenance | Less maintenance is required. | Less maintenance is required. | Requires more frequent maintenance, including cleaning and |

| Space Requirements | More compact and requires less space. | Belt conveyors are usually larger and require more space due to the size of the conveyor belt and support structure. | More compact and requires less space. |

| Cost | Low cost | High cost | High cost |

Technical parameters

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

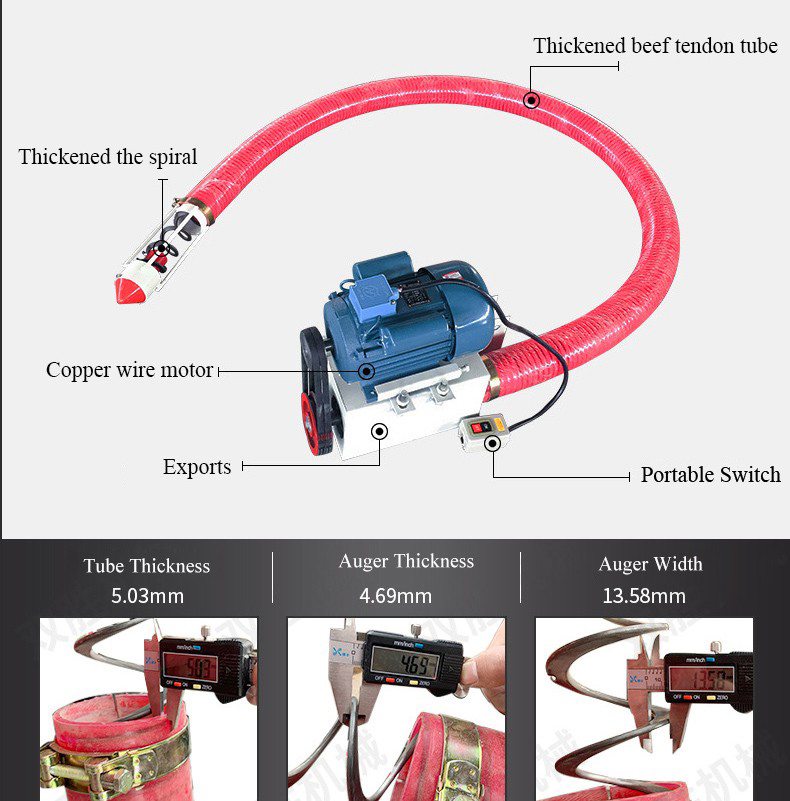

Structure of Flexible Grain Lifter

Here is a breakdown of the components and structure of a flexible grain lifter:

Flexible casing: The flexible casing is the outer covering of the conveyor. It is typically made of a durable polymer material, such as polyurethane or PVC, and is designed to be flexible and bendable. The casing is available in various lengths and diameters to fit the specific needs of the application.

Helical screw: The helical screw is the inner component of the conveyor. It is a spiral-shaped metal or plastic screw that runs the length of the casing. The screw is attached to the drive motor and rotates to move the grain along the length of the conveyor.

Drive motor: The drive motor is the power source for the conveyor. It is typically an electric motor that is attached to the end of the conveyor and drives the helical screw. The motor can be customized to meet the specific needs of the application, such as variable speed or explosion-proof motors for hazardous environments.

Grain inlet: The grain inlet is the point of entry for the grain into the conveyor. It is typically a funnel-shaped or rectangular opening that is placed near the grain source.

Grain outlet: The grain outlet is the location where the grain is released from the conveyor. It is typically a chute or pipe that directs the grain to its final destination, such as a storage bin or truck.

Solutions by Industry

Here are three customer cases of flexible grain lifters being used in various applications:

-

A small-scale food farmer needed a solution to transport harvested grain from the field to storage. They chose the flexible grain elevator because of its ability to handle different types of grain without causing damage or degradation. The flexible grain elevator's compact design also allows for easy handling in the field, and its low power requirements make it an affordable choice for farmers.

-

A malting plant needed a solution to transport germinated barley from the malting room to the drying kiln. They chose the flexible grain elevator because of its ability to handle the fragile and light malted barley without damage or loss. The flexible tube design also allows for easy installation in limited available space, and its low noise and vibration levels ensure a safe and comfortable working environment for the operator.

-

A seed processing plant needed a solution to transport different types of seeds from cleaning and sorting machines to the packing area. They chose the flexible grain elevator for its ability to handle the fragile seed without causing damage or contamination. The gentle lifting action also prevents the seeds from cracking or bruising, ensuring high quality and uniformity in the final product.