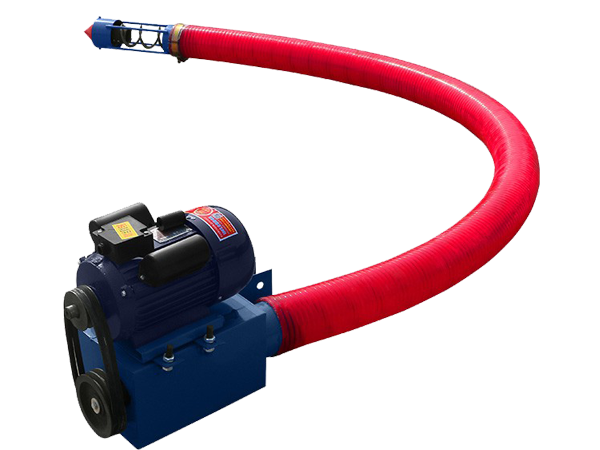

Small Grain Auger

A machine used to transport grain from one location to another, often used in agricultural operations to perform tasks such as loading and unloading grain bins, transferring grain to storage facilities, and filling planters.

Three models are available:

100mm with 5-7t/h

120mm with 7-10t/h

160mm with 10-20t/h

Conveying length: 3-30 meters

Conveying height: 2-8 meters

Power: single motor/three phase/Gasoline engine/diesel engine

Introduction of Small Grain Auger

Small grain auger, also known as a small grain suction machine, is usually used in agricultural applications, such as farms or grain storage facilities. It is a small device specially designed for rural grain transportation, loading, destacking, and storage. It can load and unload dust and granular materials , the cost is lower than any other delivery method.

When the material enters the Oxford tube uniformly and properly from the inlet, the motor (gasoline engine and diesel engine) drives the screw to rotate through the pulley, and the screw conveys the material to the outlet at one end of the chassis, and then falls into the carriage, warehouse, nylon bag and other materials place of reception.

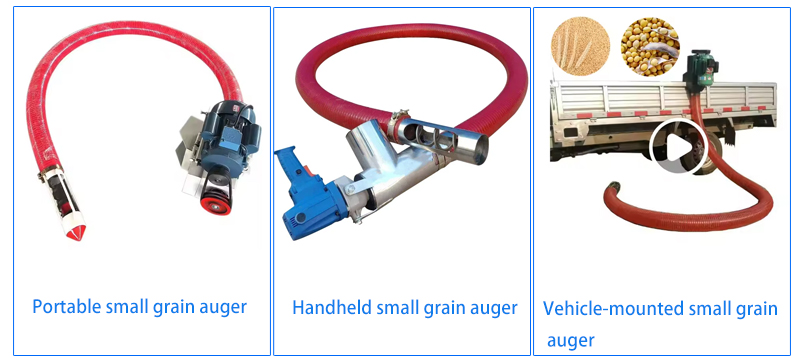

Types of Small Grain Auger

Small grain auger can be divided into portable, handheld and vehicle-mounted types according to different usage scenarios and functional requirements.

1.Portable small grain auger: usually designed as a lightweight and easy-to-carry device, suitable for occasions that require frequent movement and small-scale operations, convenient for users to carry and operate, and suitable for grain collection and transportation in farmlands, homes or small workshops.

2.Handheld small grain auger: usually designed as a small, single-person-operated device, which can be used to directly collect and transport granular materials such as grain by hand, suitable for narrow spaces, height restrictions or occasions that require delicate operations.

3.Vehicle-mounted small grain auger: usually installed on a vehicle and driven by the vehicle-mounted power system, suitable for large-area, large-volume grain collection and transportation.

Technical parameters

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

In addition to the smaller models mentioned above, small grain auger also has models such as 120mm (hourly output 7-10 tons/hour), 160mm (hourly output 9-20 tons/hour).

Application

Small grain auger plays an important role in some small-scale, limited space or frequent moving scenes due to its small and portable characteristics, improving the efficiency and convenience of material collection and transportation.

1. Farms and small grain warehouses: used for small-scale grain collection and transportation, which can easily transport grain from the field to the storage location, or from the storage location to the processing site.

2. Feed processing plant: used to absorb and transport raw materials such as feed, corn, soybean meal, etc.

3. Family farm: suitable for small-scale family farms, used to process self-grown grain.

4. Small grain processing enterprises: used for grain collection and transportation of small processing enterprises, suitable for small batch production.

Features and Benefits

Portability: Easy to move from one location to another, easy to carry.

Versatility: Ideal for handling small to medium grain loads, it can be used for tasks such as filling and emptying grain tanks, loading and unloading trucks, and transferring grain between storage facilities.

Efficiency: Grain can be transported quickly and easily, which helps to save time and labor costs, with a conveying capacity of up to 8 tons per hour.

Durability: Usually made of a strong material, such as steel, designed to withstand the wear and tear of grain. They are durable and can withstand the demands of heavy use.

Low Maintenance: There are few moving parts, which means they require very little maintenance. Regular cleaning and lubrication will help keep your conveyor running smoothly.

Viedo

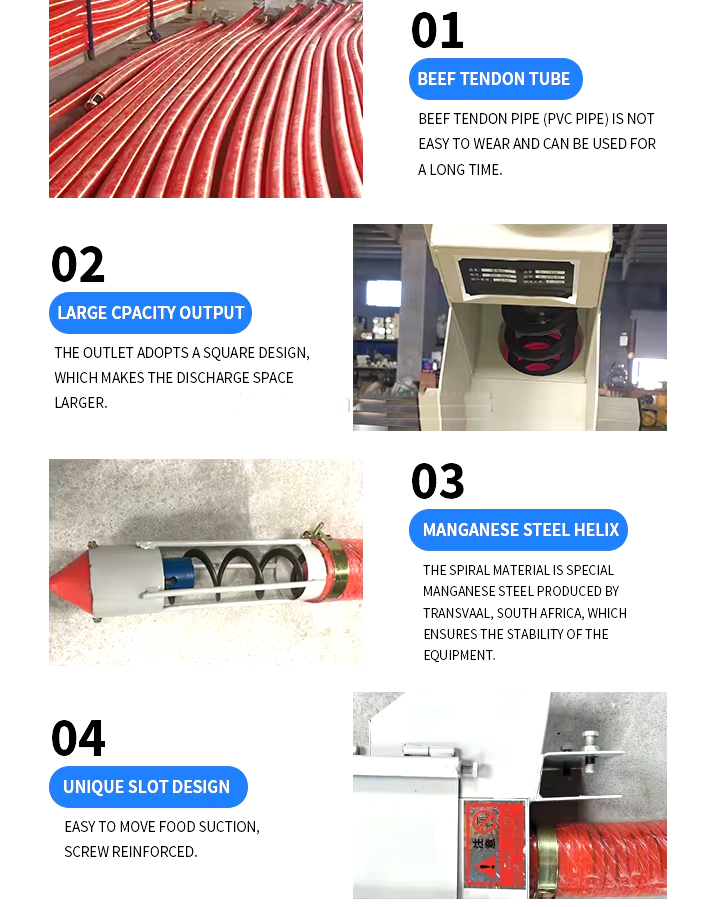

Structure of Small Grain Auger

Flexible outer tube: The spiral tube is made of high-quality beef tendon material, which is wear-resistant and cold-resistant.

Coil spring: Made of manganese steel, the helical blade adopts a shaftless structure, which facilitates the rotation of the coil spring.

Head and tail: Humanized design makes the machine convenient and fast.

Motor: The motor adopts 220V single-phase electric/380V three-phase electric, power 3-4kw.

Solutions by Industry

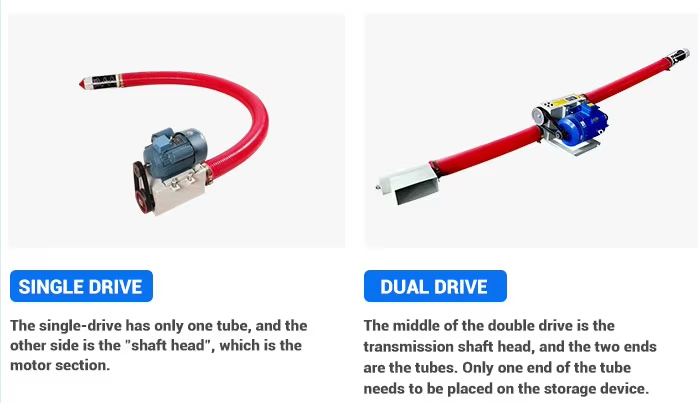

Different Configurations

1. Different appearances:

Single-drive small grain auger: It uses a single drive device, which is usually located on one side or one end of the grain auger. This design is simple and compact, suitable for some small or medium-sized operations, and suitable for some occasions with limited space or frequent movement.

Mid-drive small grain auger: The drive device is located in the middle part of the grain auger. The driving force is more uniform, which can better balance the load of the device and reduce the operating noise and vibration of the equipment. It is suitable for occasions that need to process large quantities of grain or long-term continuous operation, and can meet the needs of high-intensity and long-term use.

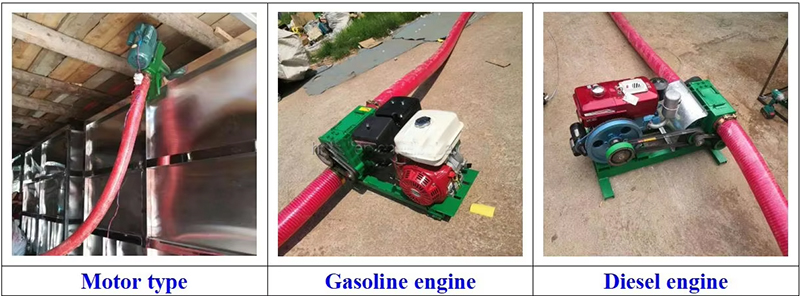

1. Different power sources

1. Single motor drive: 220V or lower voltage is used to supply a single power load, which is suitable for small or medium-sized grain collection and transportation operations, and suitable for home use.

2. Three-phase motor drive: Use three-phase power supply, voltage 380V, suitable for large-scale grain processing operations that require high power output.

3. Gasoline engine drive: Use gasoline as fuel, suitable for outdoor or no power supply occasions, such as farmland, field harvesting, etc.

4. Diesel engine drive: Use diesel as fuel, suitable for outdoor or no power supply occasions. Because diesel engines are too large and the transportation cost is high, diesel engines are generally not recommended.

Solutions by Industry