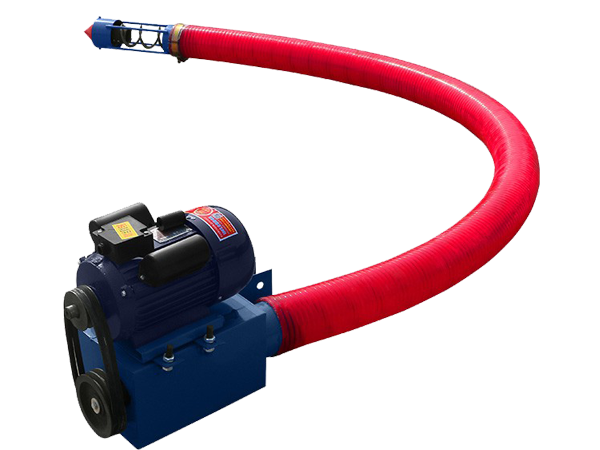

Truck Mounted Grain Auger

A truck-mounted grain auger is a piece of equipment used in the agricultural industry to move grain from one place to another. It is a portable system that can be attached to a truck and transported to different locations as needed.

Hose diameter: 100mm, 120mm, 160mm.

Length: 2-30 meters.

Vertical height: 5 meters

Delivery capacity: 2-20 tons/hour

Working voltage: 220V/380V (optional)

Introduction of Truck Mounted Grain Auger

A Truck mounted grain auger is a piece of equipment used in agriculture to load and unload grain from trucks or storage bins.It consists of a long, tubular metal pipe with a helical screw blade, known as an auger, inside. The auger is powered by a motor, typically hydraulic or electric, which rotates the screw blade and moves the grain along the length of the tube.

The standard length of the machine is 3 meters, and it can also be customized according to customer requirements. Specifications: 3 meters, 4 meters, 5 meters, 6/8/9/12 meters (can be customized), the lifting height is 5 meters, and the horizontal conveying distance can be adjusted. Up to 4-20 meters, 6-15 tons per hour, suitable for small and medium-sized farms and vendors who go to the countryside to collect grain, can be bagged and loaded, easy to use.

Types of Truck Mounted Grain Auger

Truck mounted grain auger

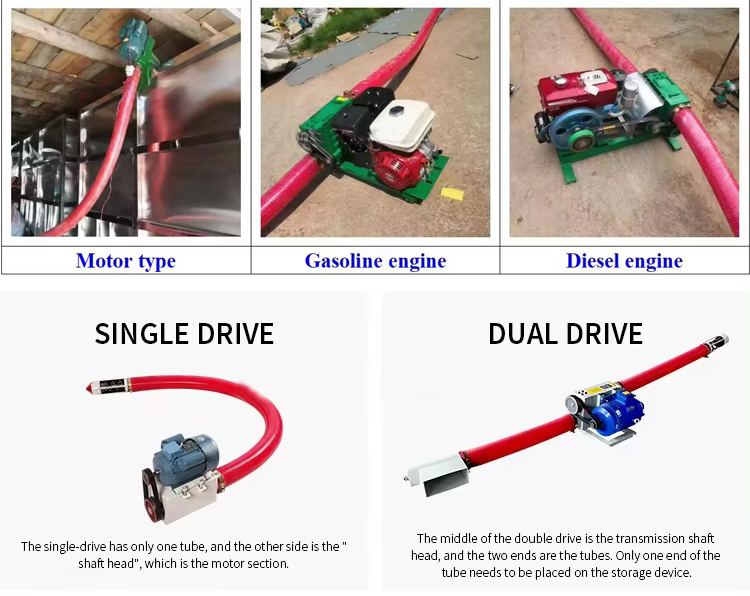

Truck mounted grain augers are usually divided into the following types:

1.Motorized truck mounted grain auger: uses an electric motor as a power source. It usually needs to be connected to a power source or powered by batteries. The machine is suitable for working in areas with power supply, such as places with power sources next to farmland.

2.Diesel engine truck mounted grain auger: uses a diesel engine as a power source. The diesel engine provides independent power, so it can operate in areas without electricity supply and is suitable for use outdoors and in more remote areas.

3.Gasoline engine truck mounted grain auger: uses a gasoline engine as a power source. Gasoline engines are usually smaller and lighter than diesel engines, and are suitable for smaller farmland or situations that require flexible movement.

Application

Truck-mounted grain augers find a wide range of applications in the agricultural sector and beyond. Some common applications include:

1.Loading and Unloading Grain: Truck-mounted grain augers are commonly used for loading harvested grain from fields into trucks for transport to storage facilities or markets. They are also used to unload grain from trucks into storage bins or silos.

2.Seed and Fertilizer Handling: These augers can be used for handling seeds and fertilizers, facilitating the efficient and controlled transfer of these materials onto fields or into storage.

3.Livestock Feed Handling: Truck-mounted grain augers can also be used for handling and transferring livestock feed, such as grains or pellets, into feed mixers or storage bins on farms.

4.Construction and Industrial Applications: In construction and industrial settings, these augers can be utilized for handling bulk materials such as sand, gravel, or other granular substances.

Features and Benefits

Mobility: One of the primary benefits of a truck mounted grain auger is its mobility. Being mounted on a truck chassis, it can be easily transported to different locations, providing flexibility in handling materials across various sites.

Efficiency: These augers are designed to efficiently move bulk materials such as grain, seeds, or fertilizers. They can quickly load or unload trucks, reducing downtime and increasing overall operational efficiency.

Versatility: Truck-mounted grain augers are versatile tools that can handle a wide range of materials beyond just grain. They can be used for various agricultural products, seeds, fertilizers, and other granular materials.

Labor Savings: Using a truck-mounted grain auger can reduce the need for manual labor in loading and unloading operations. This can lead to labor savings and increased productivity on the farm or at industrial sites.

Video

Technical parameters

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

Structure of Truck Mounted Grain Auger

A truck-mounted grain auger typically consists of the following components:

Auger tube: The auger tube is a long, hollow cylinder that transports the grain from one location to another. It is usually made of steel or other durable material and can range in diameter from a few inches to several feet.

Auger flighting: The auger flighting is a long, continuous spiral blade that runs the length of the auger tube. It is usually made of steel or other durable material and is attached to a rotating shaft at the bottom of the tube.

Power source: The power source for the auger is typically a gasoline or diesel engine that is mounted on the truck. The engine drives the rotating shaft that turns the auger flighting.

Wheels and frame: The wheels and frame provide support and stability for the auger. The frame is usually made of steel or other durable material and is mounted on the truck.

Controls: The controls for the auger are typically located on the truck and allow the operator to adjust the speed of the auger, control the direction of the grain flow, and stop the auger in case of an emergency.

Solutions by Industry

How to choose Truck Mounted Grain Auger?

When choosing a suitable truck mounted grain auger, you need to consider the following key factors:

Power Requirements: Determine the power required based on the size of your operation and the type of grain you will be handling. Grain type and density will affect the power requirements of the grain conveyor. Make sure the selected truck mounted grain auger is powerful enough to meet your operational needs.

Power source: Choose an appropriate power source based on available resources and job requirements. The motor type is suitable for areas with electric power supply, the diesel engine type is suitable for situations where there is no electric power supply or independent power is required, and the gasoline engine type is suitable for smaller-scale and flexible moving operations.

Capacity and speed: Choose a grain conveyor with the appropriate capacity and speed based on your operation needs and expected throughput. 100mm with 5-7t/h, 120mm with 7-10t/h, 160mm with 10-20t/h

Conveying length or lifting height: The longest conveying length is 30 meters, the lifting height is less than 3-8 meters, and the middle-driven truck mounted grain auger can only lift vertically 3 meters.