Flexible Screw Conveyor

A screw housed in the hose rotates along the length of the hose, moving material from one location to another. , can be conveyed in any direction, from horizontal to vertical around fixed obstacles and equipment.

Hose diameter: 100mm, 120mm, 160mm

Length: 3-30 meters

Delivery capacity: 10-12 tons/h

Drive mode: single motor/three phase/Gasoline engine/diesel engine

Voltage: 220V/380V

Power: 3-7.5KW

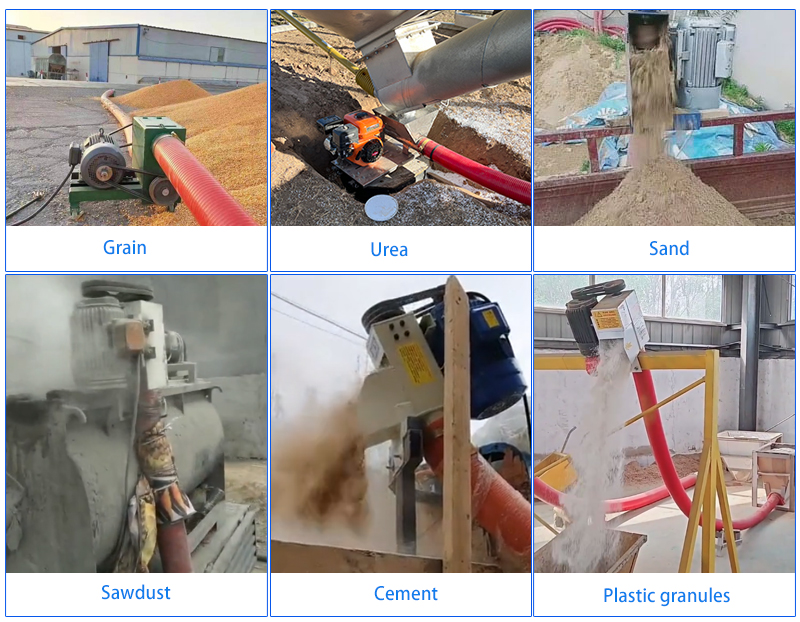

Application: suitable for grain transportation, loading, stacking, storage, etc., and can also be used to transport plastic granules, sand, feed granules

Flexible screw conveyor, also known as a flexible auger conveyor or helix conveyor, is a type of mechanical conveying system used to transport bulk materials in a flexible and efficient manner. It consists of a flexible screw enclosed in a flexible or rigid tube, with one end of the screw connected to a motor or drive mechanism.

Flexible screw conveyors can handle a wide range of bulk materials, including powders, granules, flakes, pellets, and small particles. They can be used for conveying materials such as grains, chemicals, fertilizers, plastics, pharmaceuticals, food products, and more.

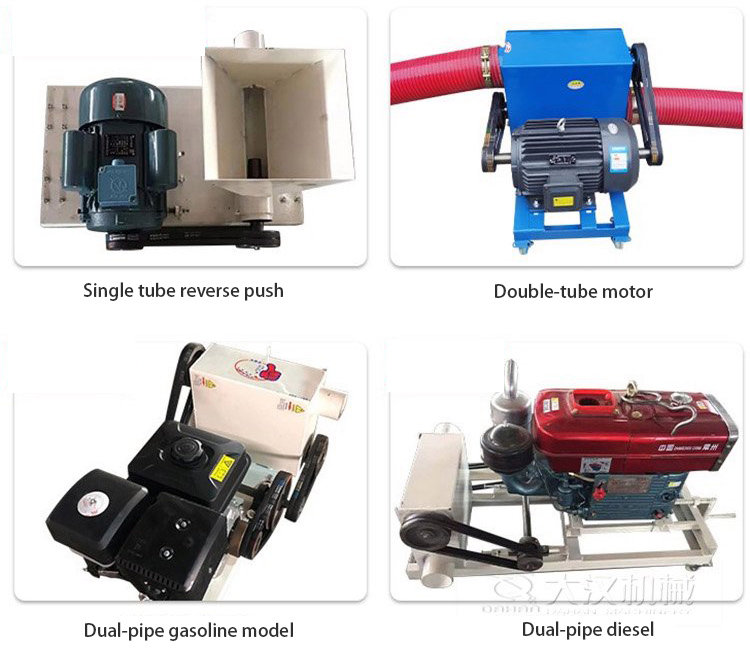

Types of Flexible Screw Conveyor

The machine is light in weight, small in model design, and small in thrust when working, which enables it to work hand-held and reduce work intensity.

2、Mobile Grain Suction Machine

The movable gripper design can clamp the side wall of the truck and realize the transportation of grain from low to high without other arrangements.

Technical parameters

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

Application

Function

Loading: The flexible screw conveyor can convey materials from storage bins, containers or other equipment to production lines or processing equipment.

Unloading: The materials can be conveyed to vehicles or containers by adjusting the angle and position to improve loading efficiency.

Pouring and bagging: When the stored materials need to be poured out or transferred to other equipment or containers, the flexible screw conveyor can pour the materials out of the hose by reversing the rotation direction of the spiral blades, which is convenient for emptying and transferring materials.

Application scenarios

Grain processing industry: used to convey powdered and granular grains such as corn, wheat, paddy, rice husks, etc.

Chemical industry: used to convey chemical raw materials such as fertilizers, plastic granules, urea, etc.

Building materials industry: used to convey cement, sand, stone, concrete and other materials, suitable for mixing stations.

Other Industries: Due to its high conveying efficiency and adaptability to a variety of materials and conveying paths, hose screw conveyors are also suitable for long-distance conveying of sand and gravel, cement, fly ash, dried sand, quartz sand, wood chips, sawdust, biomass, etc.

Video

Single Flexible Screw Conveyor Conveys Grain

Single Flexible Screw Conveyor Conveys Sand

Features and Benefits

1. One machine is multi-purpose, which can suck and transport grain, and can suck and transport granular fertilizer, feed, chemical products and other non-corrosive granular materials.

2. The Flexible Screw Conveyor is small, lightweight and designed as a flexible hose, the pipe can be bent in any direction, and can easily handle bulk material conveying at various angles.

3. It can be used for loading, bagging, warehousing or unloading of a single grain suction machine, or it can be used with other conveying equipment and screening equipment.

4. The grain suction mouth is a special suction nozzle for particle suction, which can work deep into the grain pile with a depth of 6 meters.

Features and Benefits

Difference Between Flexible Screw Conveyor and Rigid Screw Conveyor

| Difference | Flexible Screw Conveyor | Rigid Screw Conveyor |

|

|

|

| Screw shaft | Flexible spiral, no central axis | Rigid spiral with central axis |

| Conveying pipe | Flexible tube, usually made of rubber or plastic | Rigid pipe, usually made of carbon steel or stainless steel |

| Applicable materials | Suitable for dry powder, granular, flaky materials | Dry and wet powder, granular, flaky materials |

| Wear rate | Soft polymer or rubber can reduce the wear of materials compared to rigid conveyors made of metal. | Rigid spiral and pipe wall have greater wear on materials, not suitable for fragile materials. |

| Flexibility | Long conveying distance, can be bent arbitrarily according to actual needs, and adapt to complex spatial layout. | Conveying distance is limited, and pipeline layout is relatively fixed. |

| Cost | Low cost | High cost |

Structure of Flexible Screw Conveyor

Flexible screw auger conveyor is composed of five parts: a flexible outer pipe, a auger spring, the head and tail

of the machine, and motor.

Flexible outer pipe: The spiral tube is made of high-quality beef tendon material, and the tendon tube has the characteristics of wear resistance and cold resistance.

Auger spring: Made of manganese steel, the spiral blade adopts shaftless structure, which is convenient for rotating of the auger spring.

The head and tail: The user-friendly design makes the machine convenient and fast.

Motor: The motor adopts 220V single-phase electric / 380V three-term electric, power 2.2 -4kw.

The motor shaft and the coil spring are connected by a screw. When the motor is started, the motor drives the coil spring to rotate, and the grain in the collecting port will rise along the direction of the helix angle of the spring under the action of the rotating spring, and when it reaches the discharge port , Due to the action of gravity, the grain is automatically unloaded.

Available options

By drive mode:

Single drive: The motor is on the grain discharge side, with relatively small power, suitable for small operations, such as family farms and small grain storages.

Medium drive: It adopts intermediate drive mode, generally with a length of more than 10 meters, usually used for more complex transportation needs, suitable for large-scale operations.

By power type:

Motor drive: It uses electric motors as the power source, suitable for occasions with sufficient power supply, stable operation and simple maintenance.

Gasoline engine drive: It uses gasoline engines, suitable for outdoor occasions where there is a lack of power supply or mobile operations are required, with high flexibility.

Diesel engine drive: It uses diesel engines, suitable for high power requirements and long-term operations, and is usually used in agriculture and industry.

Solutions by Industry

Flexible screw conveyor manufacturers

Dahan Machinery Flexible Screw Conveyor has a length of 5-10 meters, a grain suction capacity of 2-6 tons/hour, and a weight of about 60 kilograms. Regular models will be shipped on the same day, special orders will be shipped within 7 days, and design drawings can be provided.