Wheat Grain Suction Machine

Horizontal and inclined conveying of wheat, soybean, corn, rice, sorghum, plastic, resin, rice and other particles

Length: 15m-25m

Conveying capacity: 10-12 tons/h

Voltage: 220V/380V

Introduction of Mobile Wheat Grain Suction Machine

Wheat grain suction machine is a commonly used raw material in the food production process. During the food production process, wheat often needs to be mixed with other raw materials. In order to complete the mixing process, it needs to be transported to a certain location. For example, the wheat feeding system in a food factory can be directly transported. Bulk wheat can greatly reduce the time and cost of packaging, and prevent the unloading of wheat dust from polluting the environment.

Application

The Wheat Grain Suction Machine is a Flexible Screw Conveyor designed for grain crops such as wheat, corn, soybeans, etc. It is suitable for individuals, farmers, granaries, grain buyers, flour mills, food processing plants and many other industries. Lightweight and easy to move, the Wheat Grain Suction Machine can be deployed and stowed away at any time with minimal wear and tear without compromising the integrity of the grain.

Video

Features and Benefits

1. The length of the fuselage can reach 8 meters, the grain pumping can reach 6-8 tons per hour, the horizontal conveying distance can reach 6-12 meters, and the vertical lifting height can reach 3-5 meters.

2. According to the requirements of the conveying process, it can be operated by a single unit, a combination of multiple units, or a conveying system with other equipment to meet different operational requirements.

3. Flexible pipe design, can be bent 360°, save space, and can work in narrow and curved spaces.

4. Fully automatic machine work, can run outdoors, with handheld and vehicle-mounted forms, saving labor costs and reducing labor intensity.

Structure of Wheat Grain Suction Machine

Thickened beef tendon tube: The wheat grain suction machine adopts thickened beef tendon tube, which has the advantages of cold resistance, pressure resistance and wear resistance, and can be customized for a long time.

Fully open enlarged foreign body bin: In the process of sucking grain, if there is a foreign body stuck on the screw, the foreign body can be removed by opening the screw, with high stability.

Spiral: The soft spiral is made of manganese steel, with high hardness, good elasticity and wear resistance.

Grain inlet: There is no dead angle for grain feeding, and it is more convenient to transport grain.

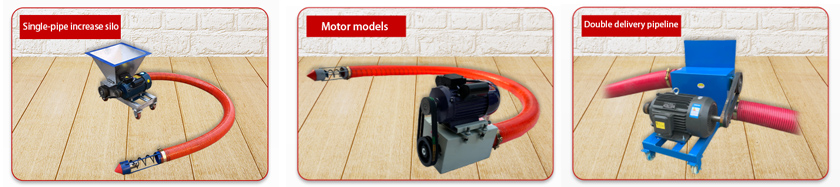

Special customization example

Technical parameters

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

Solutions by Industry

Factory service

Dahan Machinery is a manufacturer with 15 years of experience in the production of conveying equipment. We have dealt with tens of thousands of conveying problems. We not only provide products, but also provide the most appropriate solutions.

Our Wheat Grain Suction Machine has a 1-year warranty, during which we provide free repairs for loss of quality. The company has a dedicated production team, assembly team, logistics tracking team, can provide a full set of engineering drawings, rapid design within 2 hours, no need for subcontracting steps, shorten the construction period, reduce rework, standard parts inventory, special customization can be completed within 7 working days.