Alumina powder auger conveyor

Monday December-16 2024 17:28:57

Alumina powder auger conveyor can effectively transport alumina powder from one point to another within a processing or manufacturing facility, and can realize the functions of conveying, mixing, feeding, packaging and storage of alumina powder, improve production efficiency and ensure the smooth progress of the production process.

Application of alumina powder auger conveyor

The main role of auger conveyor in alumina production line:

Raw material conveying: conveying the raw materials of alumina, such as bauxite, limestone, etc., from the raw material yard to crushing, grinding and other processes.

Intermediate product conveying: conveying the intermediate products in the alumina production process, such as aluminum hydroxide in the Bayer process and roasted alumina, between different processes.

Finished product conveying: conveying the final alumina product to the packaging or storage area.

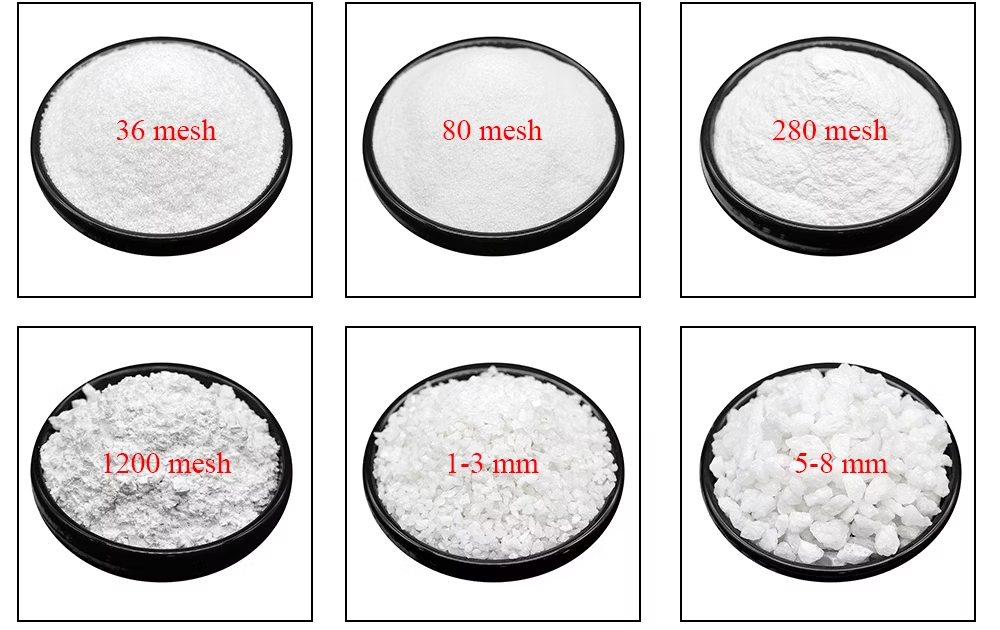

Powder conveying: Alumina powder has the characteristics of poor fluidity and easy to stick to the wall. The screw conveyor can effectively convey alumina powder and ensure the continuity of the conveying process.

Advantages of alumina powder auger conveyor

Strong adaptability: The screw conveyor is suitable for horizontal, inclined and vertical conveying, and can be customized according to process requirements.

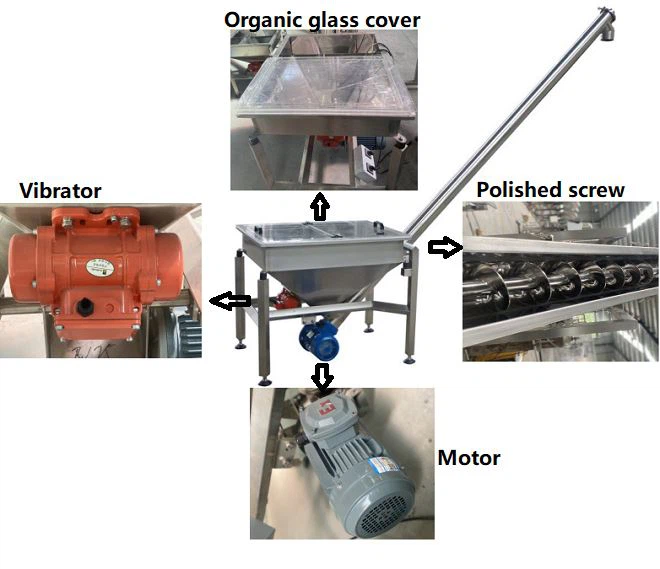

Sealed design: In order to reduce the generation and spread of dust, screw conveyors usually adopt sealed design to reduce environmental pollution.

Small footprint: The screw conveyor has a simple and compact structure and occupies a small space, which is suitable for material transportation in a limited space.

Special spiral design: In view of the characteristics of alumina powder, the screw conveyor may adopt a specially designed spiral to reduce the risk of blockage.

Wear-resistant: Wear-resistant and corrosion-resistant materials are selected to manufacture screw conveyors to reduce the wear of alumina powder on equipment and reduce losses.

How is the alumina powder prevented from clumping in the auger?

Preventing alumina powder from clumping in the auger of a screw conveyor is crucial to maintaining efficient material flow and preventing blockages. Here are some strategies to prevent clumping:

Proper material handling:Ensure that the alumina powder is stored in a dry environment to prevent moisture absorption, which can lead to clumping.

Proper auger design:Use augers with appropriate flight designs and pitches to ensure smooth material flow and prevent accumulation of powder in the conveyor.

Augers with specialized features like ribbon flights or shaftless designs can help in handling powders prone to clumping.

Auger speed and operation:Optimize the speed of the auger to ensure a consistent and controlled flow of alumina powder through the conveyor.

Regular maintenance:Regularly inspect and maintain the screw conveyor to prevent buildup of powder residue, which can contribute to clumping.

In conclusion, an alumina powder auger conveyor is a valuable tool for industries that rely on the efficient and safe handling of alumina powder. By understanding its key features and advantages, you can select the right conveyor for your specific application and optimize your production processes.