Apple food belt conveyor

Saturday December-28 2024 17:54:58

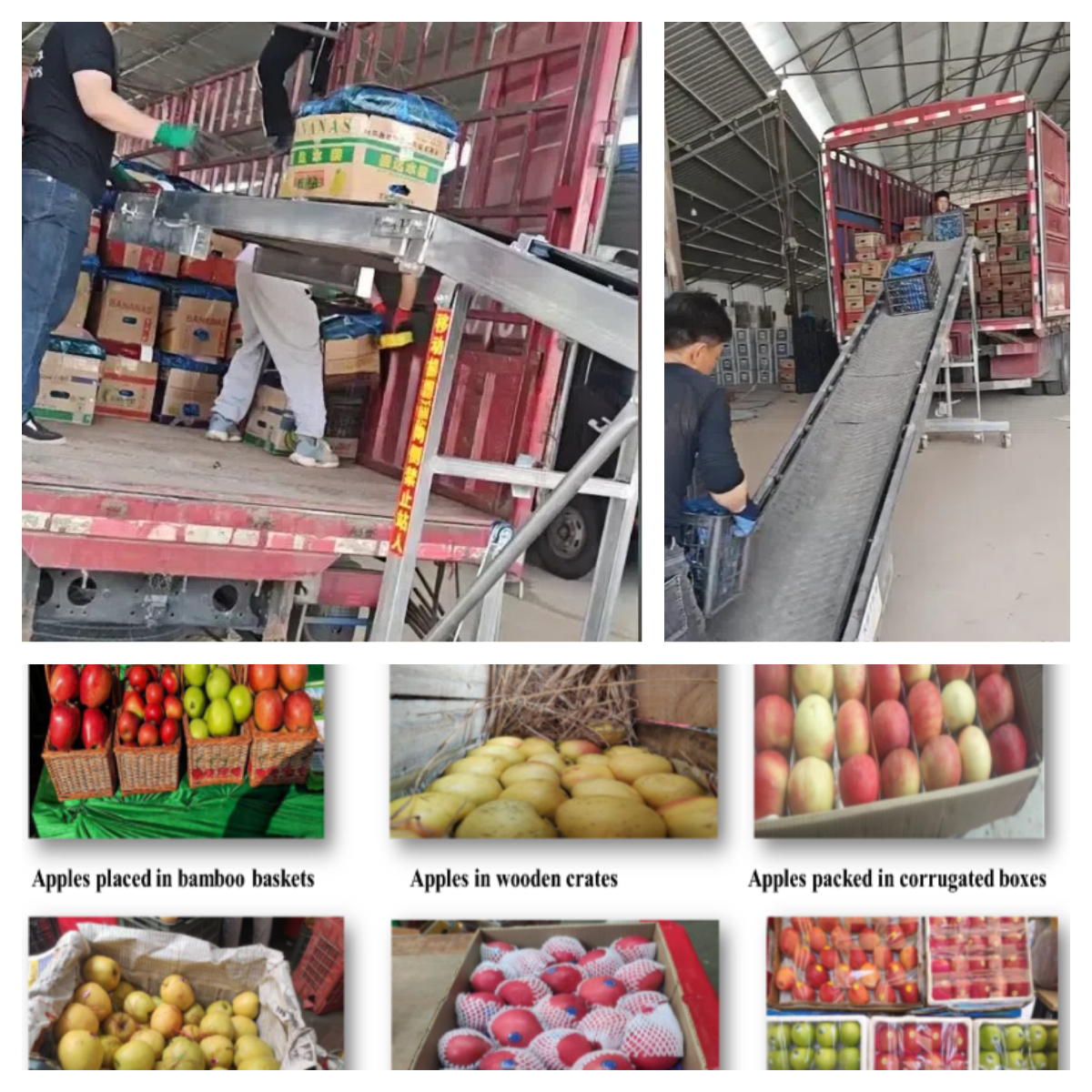

Apple food belt conveyor is used to handle apples and other foods in processing and packaging environments. It is suitable for apples in various packaging forms, such as bulk, bagged, boxed, basketed, etc. It has strong versatility and flexibility. In addition, appropriate anti-slip measures or auxiliary devices are added to the conveyor belt to ensure that apples will not slip or accumulate during transportation.Apple food belt conveyors can be integrated with other machines, such as washing machines, slicers or packaging machines, to create a streamlined production line.

Application of Apple food belt conveyor

Apple food belt conveyor has a wide range of application scenarios in the apple industry, mainly involving the production, processing, packaging and sorting of apples. The following are the specific application scenarios of apple food belt conveyor in the apple industry:

Orchard harvesting: used to transport picked apples from the orchard to the packaging station or temporary storage area to reduce manual handling and improve efficiency.

Cleaning and processing: used to transport apples to cleaning equipment, peeling machines, slicers, etc. to realize automated production line operations.

Grading and screening: used to grade and screen processed apples according to size, weight or quality to ensure product quality and uniform standards.

Packaging and boxing: used to transport packaged apples to packaging machines, packaging areas or boxing areas to improve packaging efficiency.

Quality inspection link: used to transport packaged apples to the quality inspection link to detect the appearance, quality and integrity of apples to ensure that the products meet market standards.

Refrigerated storage: When storing apples in refrigerated warehouses or storage areas, belt conveyors can be used to transport apples from the production line to storage equipment to reduce manual handling and loss.

Outbound transport: used to transport stored apples from a cold storage warehouse or storage area to a shipping area or transport vehicle, ready for delivery to the market or customers.

What types of apples can be transported by apple food belt conveyor?

Apple food belt conveyor is widely used in the food industry and can be used to transport various forms of packaged apples, including but not limited to the following:

Bulk apples: Belt conveyors can transport bulk apples, that is, unpackaged apples taken directly from the place of production or storage area.

Packaged apples: suitable for conveying bagged apples, which are usually packed in plastic bags, mesh bags or paper bags.

Boxed apples: transport packaged apples in cartons, wooden boxes or plastic boxes.

Basketed apples: transport apples in baskets or other containers, such as fruit baskets, plastic baskets, etc.

Palleted apples: conveyors can transport apples on pallets, which are usually used for large-scale transportation and storage.

Canned apples: used to transport canned apples from one location to another.

Advantages of apple food belt conveyor

Versatility: Apple conveyors can be customized to fit various production line configurations and specific needs, such as inclination, length, and width.

Hygiene and safety: These conveyors are typically made of food-grade materials such as stainless steel to ensure hygiene and prevent contamination of the food products.

Adjustable speed: The speed of the belt can usually be adjusted to control the flow of apples on the conveyor according to production needs.

Gentle handling: The design of the conveyor belt ensures that the apples are handled gently to prevent bruising or damage to the fruit.

Customizable: Apple food belt conveyors can be customized to suit the specific requirements of the production line, including size, length, width, and additional features like washing systems or sorting mechanisms.

Apple food belt conveyor selection considerations

When using a belt conveyor to transport apples, there are some key things to pay attention to to ensure that the production process is efficient, safe and meets hygiene standards:

Cleanliness: Ensure that the apple food belt Keep the conveyor and its surroundings clean, and regularly clean the belts, conveyor structures and related components to prevent cross-contamination of food.

Food-grade materials: Select belt conveyors made of materials that meet food safety standards to ensure that the conveyed apples are not contaminated.

Maintenance: Regularly perform maintenance on the belt conveyor, including lubricating bearings, adjusting belt tension and checking transmission components to ensure the normal operation of the equipment.

Reasonable adjustment of speed: According to production needs and the characteristics of apples, reasonably adjust the conveying speed of the belt conveyor to avoid damage or blockage of apples due to excessive or slow speed.

Pay attention to anti-slip: Ensure that apples do not slip or accumulate during transportation. Consider adding appropriate anti-slip measures or auxiliary devices to the conveyor belt.

Avoid squeezing: Avoid squeezing, collision or damage of apples during transportation, and ensure that the design of the conveyor belt and conveyor can protect the integrity of apples.

Overall, an apple food belt conveyor plays a crucial role in the food processing industry by providing a safe, efficient, and hygienic way to transport apples along the production line.