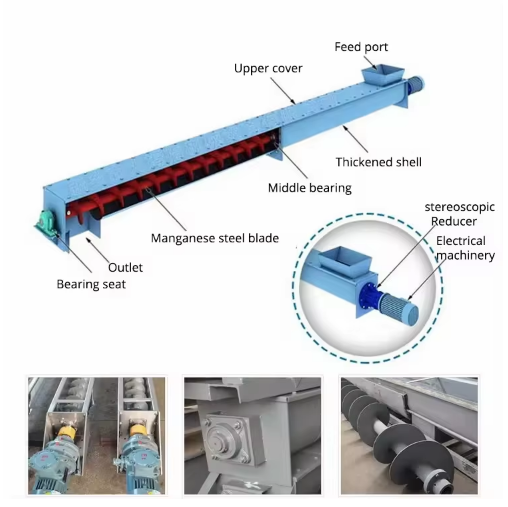

Auger conveyor for plastic scrap pellets

Tuesday September-10 2024 16:40:51

Auger conveyor for plastic scrap pellets is specially designed for conveying plastic fertilizer pellets in the recycling industry. It is ideal for transporting plastic waste pellets from one point to another within a recycling facility. The auger inside the conveyor rotates, pushing the pellets along the conveyor tube to the desired destination.

Application of auger conveyor for plastic scrap

Auger conveyor for plastic scrap pellets can be used in a variety of scenarios when handling plastic scrap pellets, including but not limited to the following aspects:

Plastic recycling plants: In plastic recycling plants, auger conveyors can be used to transport plastic scrap pellets from different processes to the next processing stage, such as from shredders to washing equipment or melting kilns.

Plastic production lines: In plastic product production lines, auger conveyors can be used to transport raw material pellets to processing equipment such as injection molding machines or extruders for automated production.

Waste treatment facilities: In waste treatment facilities, auger conveyors can be used to transport plastic scrap pellets from waste sorting equipment to crushers or other processing equipment for recycling or disposal.

Warehousing and logistics: In the field of warehousing and logistics, auger conveyors can be used to transport plastic scrap pellets to different storage areas or loading equipment for easy storage and transportation management.

Plastic recycling: In the process of plastic recycling, auger conveyors can be used to transport recycled plastic pellets to recycling processing equipment, such as extruders or injection molding machines, for the production of recycled plastic products.

Advantages of auger conveyor for plastic scrap

Efficiency: auger conveyors are known for their reliability and efficiency in transporting materials. They can operate continuously, requiring minimal maintenance and providing a cost-effective solution for handling plastic scrap pellets.

Gentle Handling: The auger conveyor's gentle action minimizes damage to the plastic pellets.

Integration: auger conveyors can be integrated into existing recycling systems and processes to streamline the handling of plastic scrap pellets.They can be connected to other equipment such as shredders, granulators, and extruders to create a continuous material handling system.

Reliability: auger conveyors are known for their durability and long service life.

Flexibility: They can be easily integrated into various production lines and storage systems.

Typical auger conveyor designs for plastic scrap

Single-Flight Screw: This is the most common design, featuring a single helical screw within the trough.

Double-Flight Screw: For higher capacities or to handle materials with varying flow properties.

U-Trough Screw: Used for elevating materials or transporting them around corners.

Factors to consider when selecting a auger conveyor for plastic scrap

Material Properties: The size, density, and flow characteristics of the plastic pellets will influence the conveyor's design.

Throughput Requirements: The desired rate of material transfer will determine the conveyor's capacity.

Distance and Inclination: The length and angle of the conveyor will impact its design and power requirements.

Environmental Factors: The conveyor's construction materials and sealing should be compatible with the operating environment.

Maintenance and Safety: Consider factors such as accessibility for maintenance and safety features like emergency stops.

Overall, utilizing a auger conveyor for handling plastic scrap pellets in recycling operations can improve efficiency, enhance material handling processes, and support sustainable practices in the recycling industry.