Bentonite clay powder auger feeder

Thursday January-16 2025 14:09:01

Bentonite clay powder auger feeder conveys bentonite powder from the storage hopper to the processing or blending point. The auger feeder is designed to handle the specific characteristics of Bentonite clay powder, such as its fine particle size and cohesive nature. By using an auger feeder, operators can ensure a consistent and reliable supply of Bentonite clay powder to downstream processes, such as mixing, blending, or packaging.

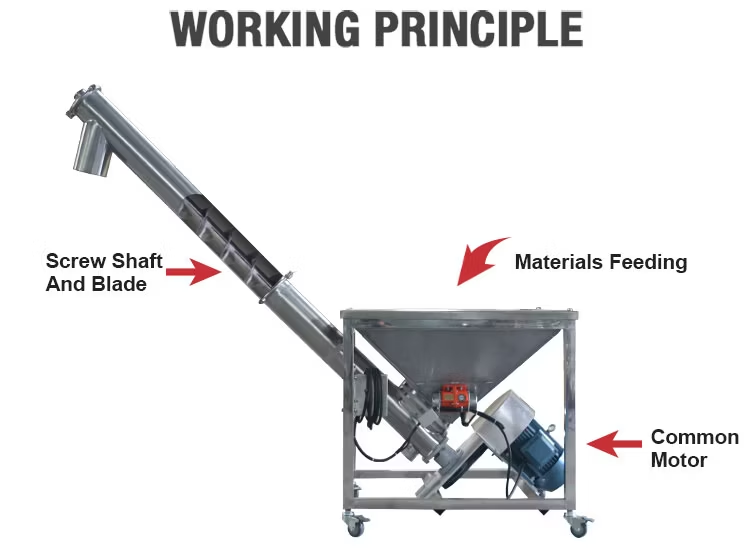

Working principle of bentonite clay powder auger feeder

Feeding: Bentonite clay powder is loaded into the hopper.

Conveying: The auger rotates, pushing the powder along the trough.

Discharge: The powder is discharged through the chute at the desired rate.

Application of bentonite clay powder auger feeder

1. Drilling fluid preparation: auger feeder can continuously and stably feed bentonite clay powder and other additives into the mixing system in proportion to ensure the quality of drilling fluid.

2. Foundry industry: bentonite clay powder can be evenly mixed with sand to ensure the bonding strength of the molding sand.

3. Papermaking industry: bentonite as a filler can improve the smoothness and printability of paper. auger feeder can evenly add bentonite clay powder to pulp.

4 Chemical industry: In the chemical production process, bentonite is often used as an adsorbent, carrier, etc. auger feeder can transport bentonite clay powder to the reactor or storage tank.

5. Sewage treatment: bentonite as a flocculant can effectively remove suspended matter in water. auger feeder can continuously and stably add bentonite clay powder to sewage.

Advantages of bentonite clay powder auger feeder

Bentonite clay powder auger feeder has the following advantages when conveying bentonite clay powder:

Precise metering: Accurate material metering and control can be achieved by adjusting the speed and feed rate of the screw to ensure accurate conveying of bentonite clay powder and avoid waste and overfeeding.

Uniform conveying: It can convey bentonite clay powder evenly, avoid blockage or unevenness during conveying, and ensure the stability and consistency of the production process.

Simple structure: The structure of bentonite clay powder auger feeder is relatively simple, and it is easy to install and maintain, which reduces the downtime and maintenance cost of the production line.

Space saving: bentonite clay powder auger feeder usually occupies a small area and can be flexibly arranged in a limited space, suitable for various production sites.

Reducing dust: When conveying bentonite clay powder through a screw feeder, the generation of dust can be effectively controlled, the working environment can be improved, and the health of employees can be protected.

Bentonite clay powder auger feeder selection considerations

Bentonite clay powder auger feeder is a common powder conveying equipment, and its selection is directly related to the equipment's efficiency and life. When selecting, the following aspects need to be considered comprehensively:

1. Material characteristics

Particle size: The particle size distribution of bentonite clay powder directly affects the gap and rotation speed of the spiral blade.

Density: The material density determines the thrust of the spiral and the motor power.

Water content: Too high water content may cause the material to stick to the spiral, affecting the conveying effect.

Flowability: Materials with poor flowability may require special spiral blade design.

2. Conveying volume: Determine the required conveying volume based on the production capacity of the production line.

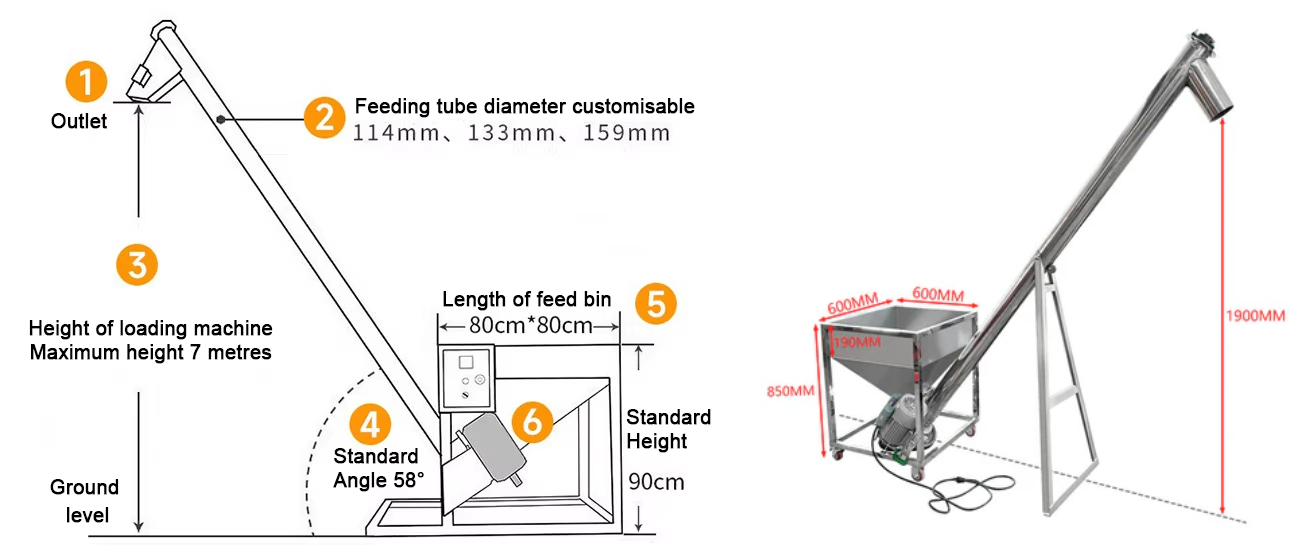

3. Horizontal distance and vertical height: The longer the conveying distance, the higher the torque requirement for the spiral.

4. Pipeline layout: The rationality of the pipeline layout affects the conveying efficiency and energy consumption.

5. Drive mode

Motor power: Select the appropriate motor power based on material characteristics, conveying volume and conveying distance.

Frequency conversion speed regulation: Frequency conversion speed regulation can achieve stepless speed regulation and improve the flexibility of transportation.

6. Auxiliary equipment

Vibrator: Prevent material bridging and ensure smooth flow of materials.

Dust removal device: Reduce dust pollution and improve the working environment.

Bentonite clay powder auger feeder can be customized to meet the specific requirements of handling bentonite clay powder, including considerations for flow rate, accuracy, and ease of maintenance. By accurately metering the powder, the auger feeder helps optimize production processes and minimize waste or inconsistencies in the final product.