Biomass pellets auger conveyor

Monday December-16 2024 17:33:59

Biomass pellets auger conveyor is a type of conveyor system specifically designed for handling and transporting biomass pellets. It uses an auger (a rotating helical screw blade) to move biomass pellets along a tube or trough to a desired location.

Working principle of biomass pellets auger conveyor

Feeding: Biomass pellets are fed into the auger conveyor from a hopper or storage bin.

Screw Mechanism: The conveyor consists of a rotating helical screw (the auger) within a tube. As the screw rotates, it moves the pellets along the length of the conveyor.

Transporting: The rotation of the screw lifts the pellets upward or pushes them horizontally, depending on the configuration of the conveyor.

Discharge: At the end of the conveyor, the pellets are discharged into a storage area, processing unit, or another conveyor system.

Common applications of biomass pellets auger conveyor

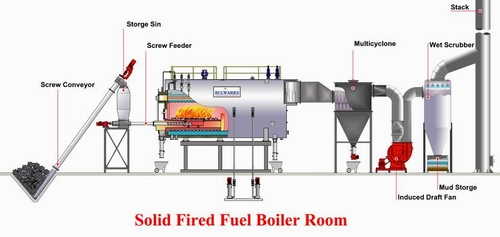

Biomass Boilers and Furnaces: Screw conveyors are often used to feed biomass pellets into boilers and furnaces.

Pellet Storage Silos: They can be used to transfer pellets from storage silos to feed points.

Pellet Production Plants: Screw conveyors are used to transport pellets within pellet production plants.

Advantages of biomass pellets auger conveyor

Efficient conveying: It can efficiently convey biomass pellets to ensure the continuity and efficiency of the production process.

Reliability: This conveyor has a simple structure, stable operation, high reliability, and can run for a long time without failure.

Wide applicability: The biomass pellets screw conveyor is suitable for biomass pellets of different types and sizes and has strong versatility.

Space saving: Compared with other traditional conveying equipment, it occupies a small area and can save production site space.

Protect pellet quality: Using the principle of screw conveying, biomass pellets are subjected to less extrusion and friction during the conveying process, which helps to protect the integrity and quality of the pellets.

Automation integration: The biomass pellets auger conveyor can be integrated with the automation system to realize the automated control of the production process and improve production efficiency.

Low cost: Compared with other conveying equipment, the manufacturing cost and operating cost are lower, making it an economical choice.

How to choose a biomass pellets auger conveyor?

Capacity: The capacity required of the conveyor in terms of pellet flow rate.

Distance: The distance the pellets need to be transported.

Vertical lift: The height the pellets need to be lifted if vertical transport is required.

Pellet size and moisture content: The size and moisture content of the pellets will affect the performance of the conveyor.

Environmental conditions: The operating environment, such as temperature and humidity, will affect material selection and design.

Biomass pellets auger conveyor is essential in the biomass processing industry, enhancing the efficiency of material handling and contributing to the overall productivity of operations. Its robust design, versatility, and efficiency make it a valuable asset for any facility dealing with biomass pellets.