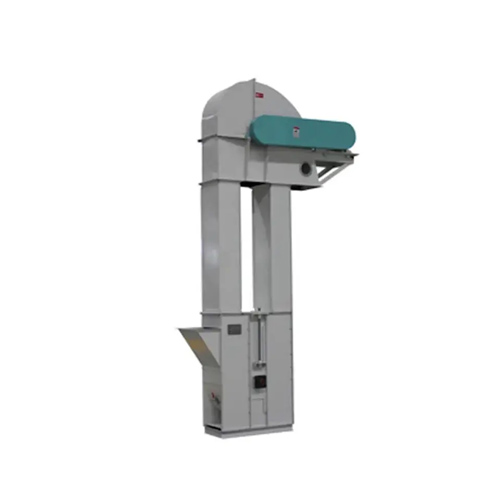

Bucket Elevator In Cement Plant

Tuesday July-25 2023 14:12:55

What is bucket elevator in cement plant?

Bucket elevator in cement plant is a kind of equipment used to vertically lift bulk materials (such as cement, ore, coal, etc.) to a certain height. It is composed of hoist tower, hoist bucket, driving device and so on. The working principle of the bucket elevator is to use the bucket elevator bucket to grab the bulk material from the discharge port under the guidance and pulling action of the elevator tower, and rise along the elevator bucket chain, and finally unload it at the target position. Bucket elevator in cement plant has the characteristics of simple structure, stable operation and low energy consumption, and is widely used in bulk material transportation projects in cement plants and other related industries.

Working Principle

The working principle of bucket elevator in cement plant is to drive the chain wheel or pulley to rotate through the motor, so that the chain or belt drives the bucket to move in a circular manner. During the movement, the material enters the bucket, and under the action of gravity and the traction force of the chain or belt, the material is lifted to the set height and falls naturally by gravity. During the whole process, the gravity, the traction force of the chain or belt and the friction force of the material itself interact to realize the continuous lifting and conveying of the material.

Advantages

1. Large conveying capacity: Bucket elevator in cement plant can choose the appropriate frame height and bucket length according to the production requirements, provide different conveying capacities, and adapt to different process requirements.

2. Long conveying distance: Bucket elevator in cement plant can be installed in multiple sections according to the needs, so as to meet the material conveying distance requirements on the production line to the greatest extent.

3. Simple and reliable structure: The structure of the bucket elevator is relatively simple, consisting of a small number of components, easy to install and maintain, and high in reliability.

4. With automatic control function: Bucket elevator in cement plant can be integrated with the control system to realize automatic control and improve production efficiency and work safety.

Types

According to different usage scenarios and requirements, bucket elevators in cement plants can be divided into various types. Common types include:

1. Bucket Elevator: This is the most common type of elevator in a cement plant, where a series of buckets are hung on the chain, and the material is lifted to the target position by the lifting motion of the chain. The bucket elevator has the characteristics of simple structure, stable operation and large conveying capacity, and is suitable for use in small and medium-sized cement plants.

2. Chain plate elevator: Different from the bucket elevator, a plate is directly welded on the chain of the chain plate elevator without bucket processing. The chain plate elevator is suitable for the situation where the material particles are large and viscous, and can effectively transport the adhered material.

3. Bucket elevator: The bucket elevator is a special bucket elevator. Compared with the ordinary bucket elevator, its bucket shape is more special, like a bucket. The bucket elevator is suitable for the transportation of wet materials and powder materials, and can effectively prevent materials from being scattered and spilled.

Application

Bucket elevators in cement plant are widely used in the material transportation process of cement, chemical industry, metallurgy, electric power, mining and other industries. Its main application scenarios include:

1. Cement production line: used to transport cement clinker, limestone and other materials from underground mines or stockyards to kiln front silos or crushing devices.

2. Chemical production line: used to transport chemical raw materials, finished powder or granules and other materials, such as chemical fertilizers, plastic granules, etc.

3. Metallurgical production line: used to transport concentrate, coke and other materials, such as iron ore, copper ore, etc.

4. Electric power industry: used to transport fuel materials such as pulverized coal.

5. Mining industry: used to transport ore, coal gangue and other impurity materials.

In short, bucket elevator in cement plant is a widely used material conveying equipment. With its advantages of simple structure, high reliability and strong adaptability, it has become an indispensable important equipment in the process of material handling in various industries.