Cement Suction Machine

Thursday May-08 2025 17:03:03

What is a cement suction machine?

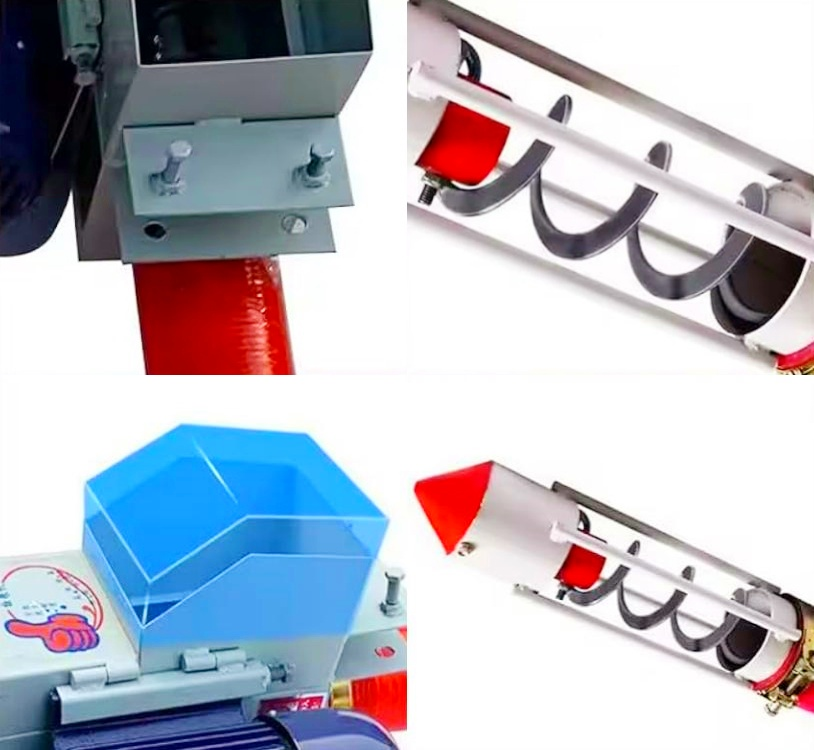

Cement suction machine is an industrial equipment used to convey and screen dry cement powder, which is commonly used in the fields of construction, building materials, warehousing and so on. The equipment uses negative pressure airflow to suck bulk cement into the machine through a hose, and then screens it through a screen to remove impurities and improve the purity of the material. It is often equipped with a screen mesh of 60 to 120 mesh, which is suitable for on-site construction or bulk cement loading and unloading operations. Depending on the conveying volume, the conveying capacity of common models is 3 to 10 tons/hour.

The core function of the cement suction machine

Suction of cement: Through negative pressure or mechanical power, the cement slurry, solidified residue or dust in the ground, pipeline or container is sucked into the equipment. The suction port can be equipped with auxiliary devices such as hoses, suction nozzles, filters, etc. to adapt to different working conditions.

Conveying cement: The absorbed cement material is transported over a long distance through the conveying pipeline to ensure that the cement will not leak or adhere to the pipeline wall during the transportation process. The conveying distance can range from tens of meters to hundreds of meters, which can meet the material transportation requirements of different places such as cement plants and construction sites.

Solid-liquid separation: During the transportation process, the cement material is separated from the air to avoid environmental pollution caused by dust emissions, while ensuring that the material can be accurately stored or enter the next production link.

What is the working principle of the cement suction machine?

① At the suction nozzle, due to the negative pressure, the outside air and cement powder form a mixture and are sucked into the feed pipe.

② The mixture is transported to the material-gas separation device in the feed pipe, such as a cyclone separator or a bag dust collector. In the separator, the cement particles are separated from the air by centrifugal force, gravity or filtration.

③ The separated cement particles fall into the storage bin below or directly enter the subsequent processing equipment.

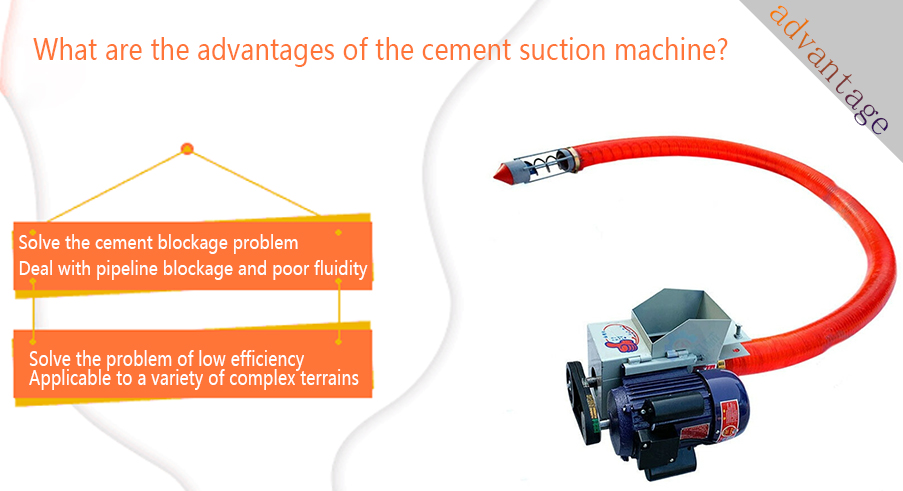

What are the advantages of the cement suction machine?

Solve the cement blockage problem: The feed port of the cement suction machine is usually designed with a larger diameter and a certain inclination angle to facilitate the smooth entry of cement into the machine and reduce the possibility of material accumulation and blockage. Vibrate or stir to keep the cement loose to prevent agglomeration and bridging.

Deal with pipeline blockage and poor fluidity: Cement is fine and sticky. During the transportation process, especially in humid or long transportation distances, pipeline blockage is easy to occur. Use a large-diameter, less-elbow pipeline layout to reduce resistance; the inner wall is coated with an anti-stick coating to reduce cement adhesion. Clean the inner wall of the pipeline regularly.

Solve the problem of low efficiency: The traditional intermittent conveying method is relatively inefficient, requires manual loading and unloading, and is time-consuming and labor-intensive. The cement suction machine realizes continuous automatic conveying. Once the system is started, cement can be continuously transported from the silo to the destination, greatly improving the conveying efficiency and production efficiency.

Applicable to a variety of complex terrains: For factories with complex terrain or occasions where transportation needs to cross obstacles, traditional mechanical conveying methods may be limited. The pipeline of the cement suction machine can be flexibly arranged according to actual needs, horizontally, vertically, and inclined, and can easily bypass obstacles and transport cement to the designated location, showing its high flexibility.

Technical parameters of cement suction machine

|

Host type |

Length |

Pipe diameter (inch) |

Efficiency (hour/ton) |

Motor power (kW) |

Lifting height (m) |

Machine weight (kg) |

|

220V-380V single power |

3 meters |

3.5 |

5-6 |

2.2 |

2 |

60 |

|

4 meters |

3.0 |

2.5 |

64 |

|||

|

5 meters |

3.0 |

67 |

||||

|

6 meters |

3.5 |

70 |

||||

|

7 meters |

73 |

|||||

|

8 meters |

3.0 enlarged motor |

82 |

||||

|

9 meters |

3.0 Larger motor |

3.0 |

85 |

|||

|

10 meters |

4-5 |

88 |

||||

|

11 meters |

92 |

|||||

|

12 meters |

95 |

|||||

|

4 meters |

7.8 |

3.0 |

2.0 |

65 |

|

|

|

220V-380V single electricity |

4 meters |

4 |

7.8 |

3.0 |

2.5 |

68 |

|

5 meters |

3.5 |

71 |

||||

|

6 meters |

75 |

|||||

|

7 meters |

3.0 enlarged motor |

3.0 |

80 |

|||

|

8 meters |

3.5 |

83 |

||||

|

Note: Length and pipe diameter can be customized! |

||||||

Note: Length and pipe diameter can be customized!

Selection recommendations for cement suction machine

Conventional cement suction operation: Use polyester coated cloth bags or nanofiber filter elements, the filtration accuracy can reach 3000 mesh (about 5μm), which can meet industrial dust collection and environmental protection standards.

Working conditions with dust recovery requirements: High-precision filter materials can be selected, such as PTFE coated filter cartridges, with a filtration accuracy of 5000~10000 mesh.

High temperature or special working conditions: For example, when conveying high-temperature clinker cement, it is recommended to use high-temperature resistant aramid filter media and select the appropriate filtration accuracy.

For fine-particle materials such as cement powder, the recommended filtration accuracy mesh is as follows:

|

Filter level |

Filter accuracy |

Corresponding mesh |

Applicable scenarios |

|

Ordinary dust removal |

5~10 microns |

About 1500~3000 mesh |

Applicable to general cement suction and delivery, no high cleanliness requirements |

|

High-efficiency dust removal |

1~5 microns |

About 3000~10000 mesh |

Applicable to factories or confined spaces with high environmental protection requirements |

|

Ultra-high accuracy |

≤1 micron |

>10000 mesh |

Usually used for fine powder or harmful gas control, non-standard cement delivery occasions |

Application of cement suction machine

Cement production field: In the raw material processing link of cement plants, cement suction machines can be used to transport raw materials such as limestone, clay, and iron ore from the yard to the production workshop. After cement is produced, it needs to be packaged and transported. The cement suction machine can transport cement from the storage bin to the packaging machine to achieve automatic packaging. The packaged cement bags are then transported to the warehouse or directly loaded and transported by conveying equipment. In addition, for bulk cement, the cement suction machine can transport cement from the storage tank to the bulk cement transport vehicle.

Construction field: The cement suction machine can transport cement from the transport vehicle or temporary storage point to the mixer or construction floor. In interior decoration, the cement suction machine can be used to transport cement to areas where wall plastering, floor leveling or tile pasting is required. Workers can use a small cement suction machine to accurately transport cement to the construction location, avoiding the dust and labor intensity that may be caused by manual handling of cement bags.

Cement product processing field: In concrete product factories, such as prefabricated board factories, cement pipe factories, etc., the cement suction machine can accurately transport cement to the concrete mixer, mix it with sand, gravel, water and other raw materials in a certain proportion, and produce concrete products of different strengths and uses. The accuracy of the concrete mix ratio can be guaranteed by the precise transportation of the cement suction machine. On the cement brick production line, the cement suction machine transports cement to the batching system, mixes it with other additives and aggregates, and then makes cement bricks through processes such as pressing.

Cement suction machine usually refers to equipment used to suck and transport cement powder. This type of equipment is usually used in the construction industry, warehouses, ports, etc., and can efficiently handle cement and other powdered materials. If you want to know the specific model of a certain type of cement suction machine, can you provide more details, such as the type of equipment you need to suck cement, or do you have other specific requirements? This way we can better help you.