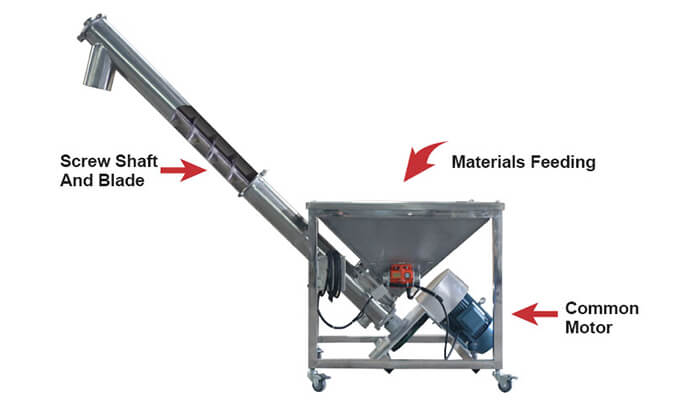

Cereal screw conveyor

Friday December-27 2024 17:40:50

Cereal screw conveyor can transport cereals quickly and continuously, suitable for large-scale production lines to ensure production efficiency. In the production process of cereals, screw conveyors can connect different processing links, such as conveying from the mill to the mixer. In the packaging link, screw conveyors can efficiently transport cereals to the packaging machine to ensure a smooth production process.

Function of cereal screw conveyor

The screw conveyor transports cereal from one place to another along the pipe or channel of the conveyor by spiral rotation. In cereal production, the screw conveyor can be used in the following aspects:

Feeding: transporting raw cereal from storage bins or containers to processing equipment, such as dryers, roasters, etc.

Mixing: It can be used to mix different types or batches of cereals to ensure product uniformity.

Packaging: On the packaging production line, the screw conveyor can help transport cereal to the packaging machinery quickly and efficiently, improving production efficiency.

Unloading: Transporting the processed cereal from the production line to the packaging area or storage bin for use.

Application of cereal screw conveyor

The application scenarios of cereal screw conveyor include the following aspects:

1. Grinding to mixing: In the cereal production process, after the mill grinds the raw materials into powder, the powder is conveyed to the mixer by a screw conveyor to mix with other ingredients (such as sugar, spices, etc.).

2. Mixing to the molding machine: The mixed cereal is conveyed to the molding machine by a screw conveyor to ensure uniform feeding and consistency of the finished product.

3. Molding to the baking oven: After molding, the screw conveyor can convey the cereal to the baking oven for heating treatment.

4. Cooling after baking: After baking, the cereal needs to be cooled, and the screw conveyor can convey the hot cereal to the cooling area to avoid the subsequent processing due to excessive temperature.

5. Cooling to the sieving machine: The cooled cereal is conveyed to the sieving machine by a screw conveyor to remove unqualified particles and ensure product quality.

6. Conveyor to the packaging machine: In the packaging stage, the screw conveyor conveys qualified cereal to the automatic packaging machine to achieve fast and accurate packaging.

7. Transport to storage tank: After production is completed, the screw conveyor can transport the cereal to storage tanks or silos for subsequent inventory management and distribution.

Advantages of cereal screw conveyor

1. Continuous operation: It can achieve continuous and stable transportation, is suitable for large-scale production, and significantly improves production efficiency.

2. Gentle handling and reduced damage: The spiral design reduces the mechanical impact on the cereal during transportation, effectively maintaining the integrity and appearance of the cereal and avoiding breakage.

3. Small space occupation: The vertical or inclined installation method of the cereal screw conveyor saves production line space and is suitable for use in environments with limited space.

4. Strong sealing: The sealing design can effectively prevent dust leakage and keep the working environment clean, especially suitable for handling fragile cereal.

5. Flexibility: It can be flexibly installed according to the layout of the production line, adapt to different conveying heights and angles, and is easy to connect with other equipment.

6. Precision adjustment: When used in conjunction with an automatic control system, it can achieve precise control of the conveying speed and flow rate, improving overall production efficiency.

Selection suggestions for cereal screw conveyor

Choosing the right cereal screw conveyor is crucial to ensuring production efficiency and product quality. Here are some recommended selection points:

Conveying Capacity: Determine the amount of cereal you need to convey, including the weight or volume that needs to be processed per hour. root

Conveying distance and height: Consider where the cereal needs to be transported from and to, including horizontal distance and vertical height.

Conveying speed: According to the speed requirements of the production line and the characteristics of the cereal (such as density, particle size, etc.), select the appropriate conveying speed to ensure that the cereal can be smoothly conveyed and not damaged during the production process.

Material selection: Choose sanitary materials suitable for the food industry to ensure that the conveyor components meet food safety standards and avoid contamination of cereals.

Spiral design: Consider parameters such as the spiral diameter, pitch and spiral pitch ratio, and select the appropriate spiral design based on the characteristics of the cereal and conveying requirements to ensure that the cereal can be conveyed evenly and stably.

By using the cereal screw conveyor, manufacturers can realize the automated conveying of cereal, thereby improving production efficiency and the overall operating efficiency of the production line.